Heat-dissipating method of LED (Light-Emitting Diode) heat-dissipating module and LED heat-dissipating module

A technology of LED modules and heat dissipation modules, applied in lighting and heating equipment, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve the problems of shortened service life, high cost, and excessive use of materials. Achieve the effect of reducing the speed of light decay, solving heat dissipation problems, and increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

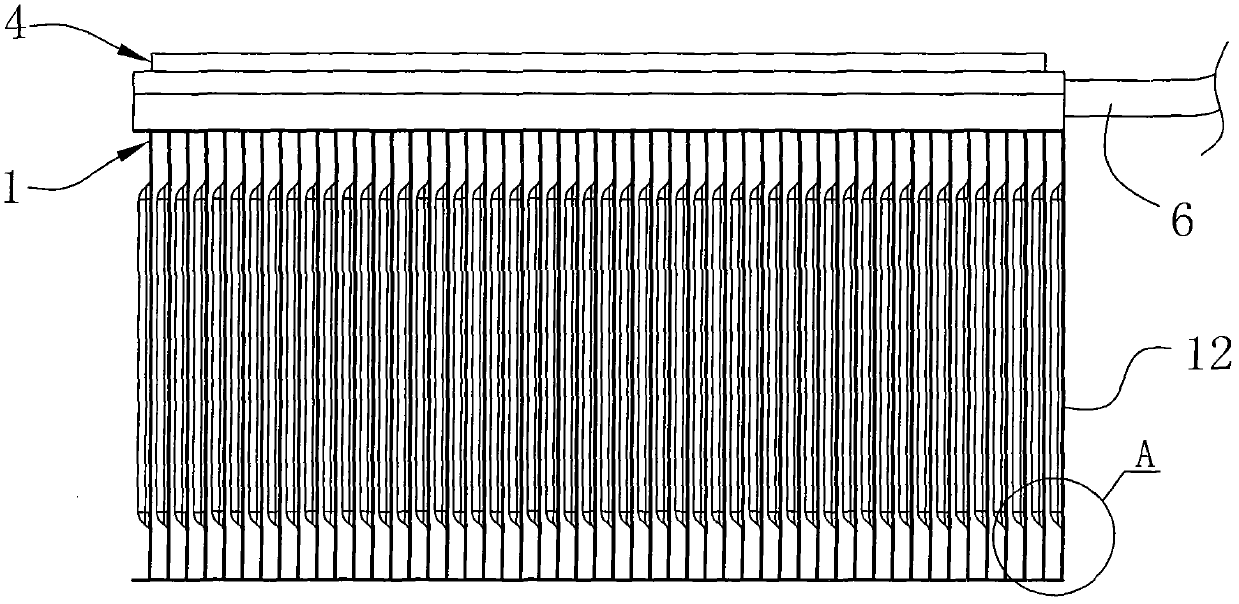

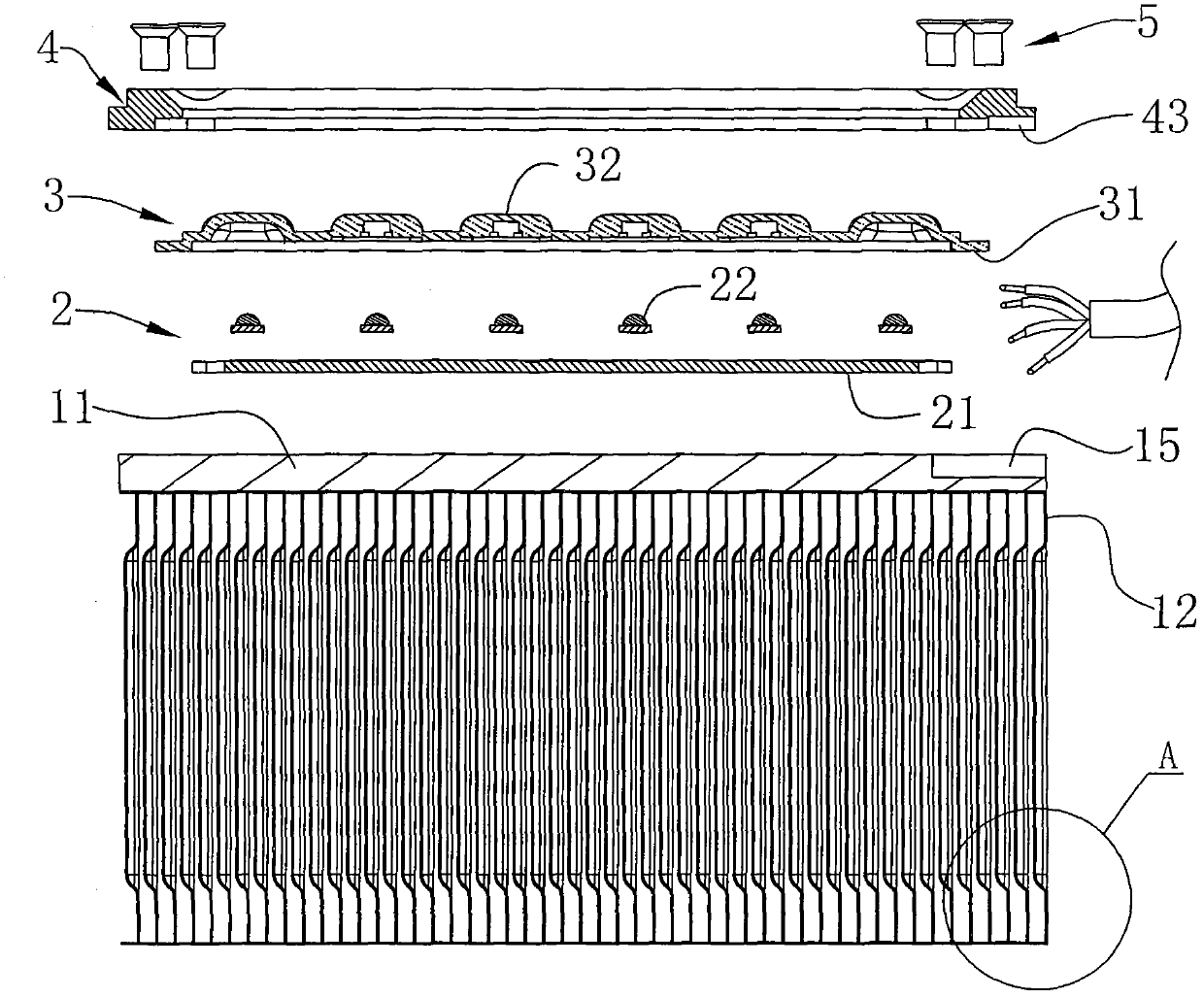

[0032] Example: see Figure 1 to Figure 4 , an embodiment of the present invention provides a heat dissipation method for an LED heat dissipation module, which includes the following steps:

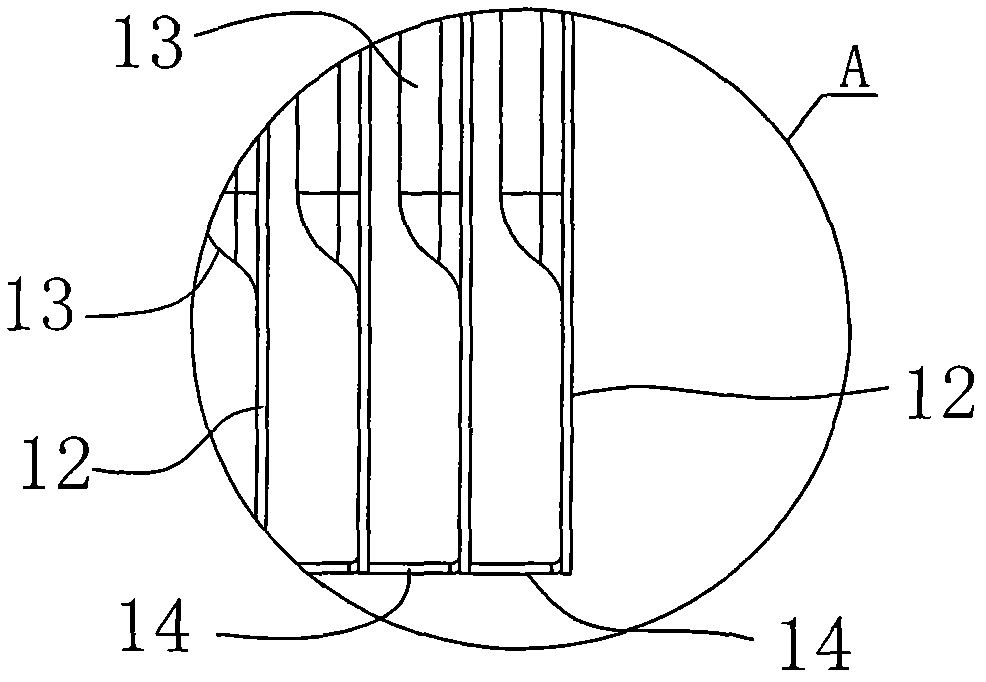

[0033] (1) Preparation of cooling fins 12: prepare sheet metal material, punch it, punch it, and shape it to produce a plurality of cooling fins 12, and the middle part of each cooling fin 12 has multiple rows side by side to enhance its structural strength and increase The heat dissipation area and the elongated vertical protrusion 13 for improving the heat dissipation effect, the top of the heat sink 12 is provided with an insertion part, and the bottom edge of the heat sink 12 is provided with at least one fixed foot 14;

[0034](2) Preparation of heat dissipation bottom plate 11: prepare plate-shaped metal material, punch it, drill holes, and shape it to produce a heat dissipation bottom plate 11, and on the bottom surface of the heat dissipation bottom plate 11, there are a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com