Outward double-row tapered roller bearing inner race measurement method

A technology for tapered roller bearings and measuring methods, which is applied in the directions of measuring devices, mechanical measuring devices, and mechanical clearance measurements, etc., and can solve problems such as difficulty in ensuring dimensional accuracy and difficulty in grinding the small end face of the inner ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

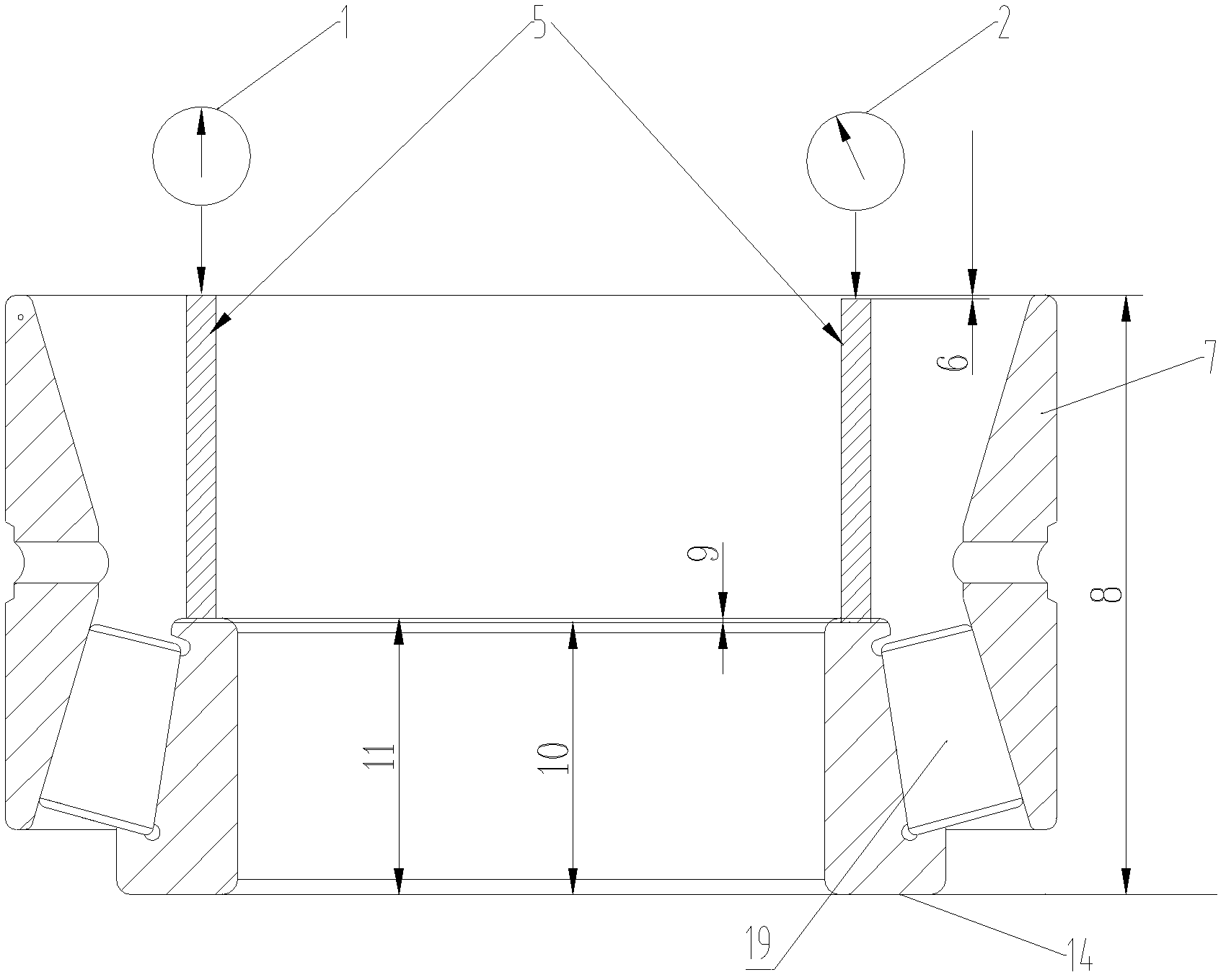

[0041] 352064 bearings, the national standard stipulates that the inner ring width is 100(0~-0.40)mm, the outer ring width is 168(0~-0.40)mm, the assembly height is 220(+0.8~-0.8)mm, α=17°, group C0 Axial clearance: (0.46~0.68) mm. Inner ring raceway B1=B2=220mm-100mm-(220-168)mm÷2=94mm.

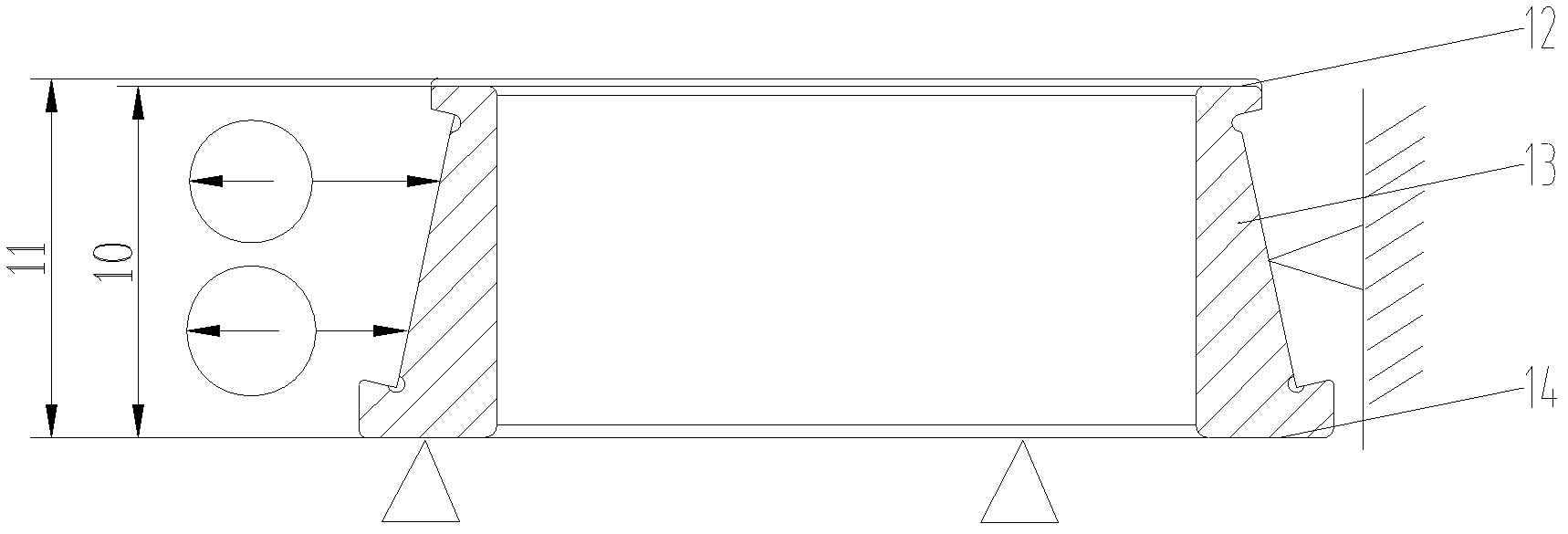

[0042] (1) Taking the small end face 12 of the inner ring as the reference, the measurement steps are as follows:

[0043] ① Process the actual width of the inner ring from 10 to 100 (0~-0.40) mm;

[0044] ② Grinding and processing the inner ring raceway B1 and raceway B2 based on the large end face 14 of the inner ring;

[0045] ③Measure the inner ring raceway B1 and raceway B2 based on the small end face 12 of the inner ring:

[0046] Such as Figure 4 As shown, the measured size range of the raceway B1 is about 94 (-0.017~+0.017) mm, and the measured size range of the raceway B2 is about 94 (-0.017~+0.017) mm, that is, the two inner rings Due to the difference in the size of the race...

Embodiment 2

[0058] 352236 bearings, the national standard stipulates that the width of the inner ring is 86 (0~-0.25) mm, the width of the outer ring is 152 (0~-0.25) mm, the assembly height is 192 (+0.5~-0.5) mm, α=16°41'57 ”, C0 group axial clearance: 0.23mm~0.36mm. Inner ring raceway B1=B2=192mm-86mm-(192-152)mm÷2=86mm.

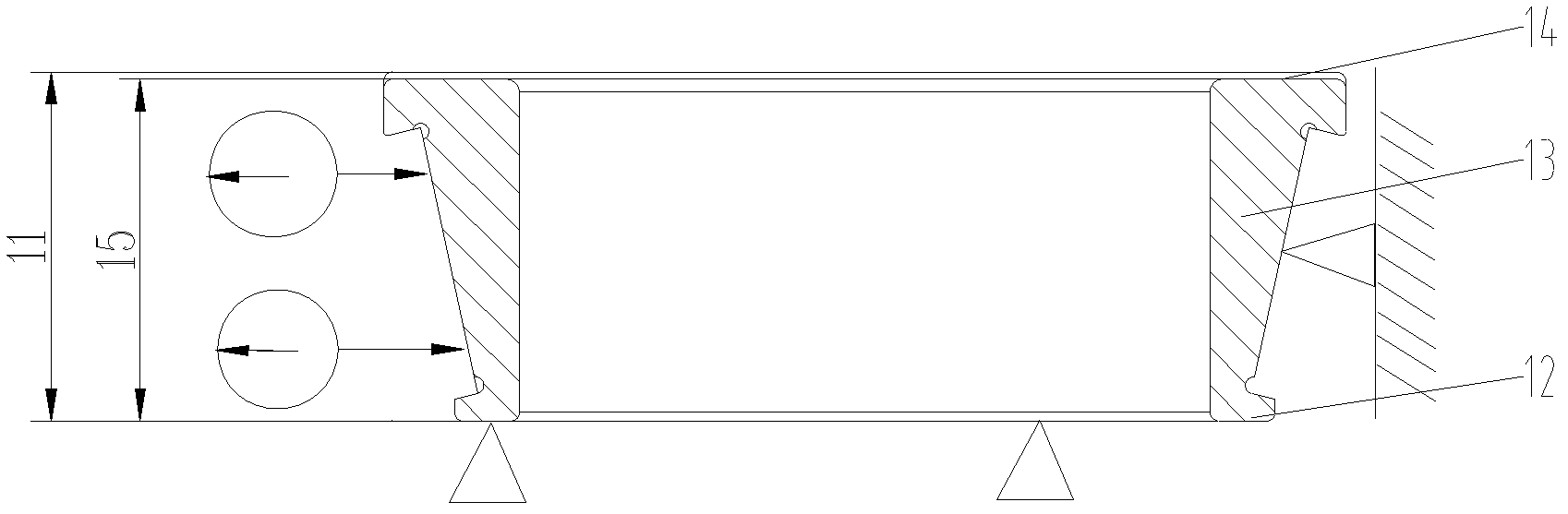

[0059] (1) The measurement steps based on the small end face are as follows:

[0060] ① Process the actual width of the inner ring from 10 to 86 (0~-0.25) mm;

[0061] ② Grinding and processing the inner ring raceway B1 and raceway B2 based on the large end face 14 of the inner ring;

[0062] ③Measure the inner ring raceway B1 and raceway B2 based on the small end face 12 of the inner ring:

[0063] like Figure 4 As shown, the measured size range of raceway B1 is about 86 (-0.017~+0.017) mm, and the size range of raceway B2 is about 86 (-0.017~+0.017) mm, that is, the two inner ring raceways Due to the difference in processing size, the maximum actual axial clear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com