10kv-35kv optical fiber composite overhead insulated cable with rated voltage

An overhead insulated cable and optical fiber composite technology, which is applied in the direction of insulated cables, power cables for overhead applications, communication cables for overhead applications, etc., can solve the problems of increasing investment costs and increasing construction complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

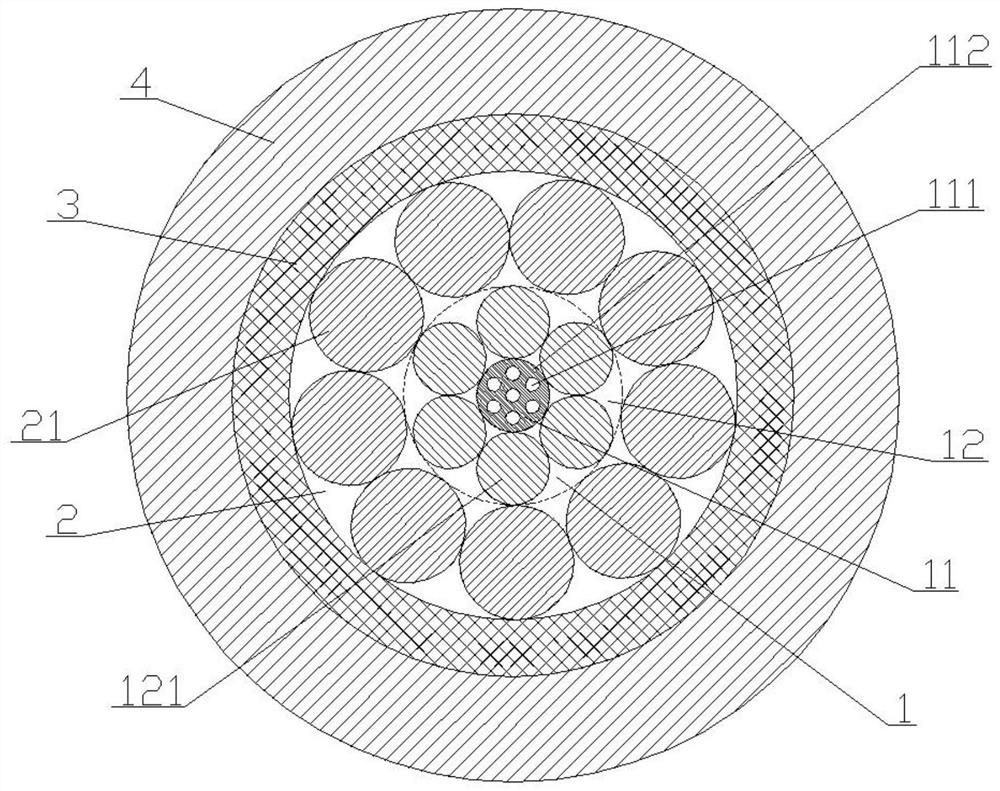

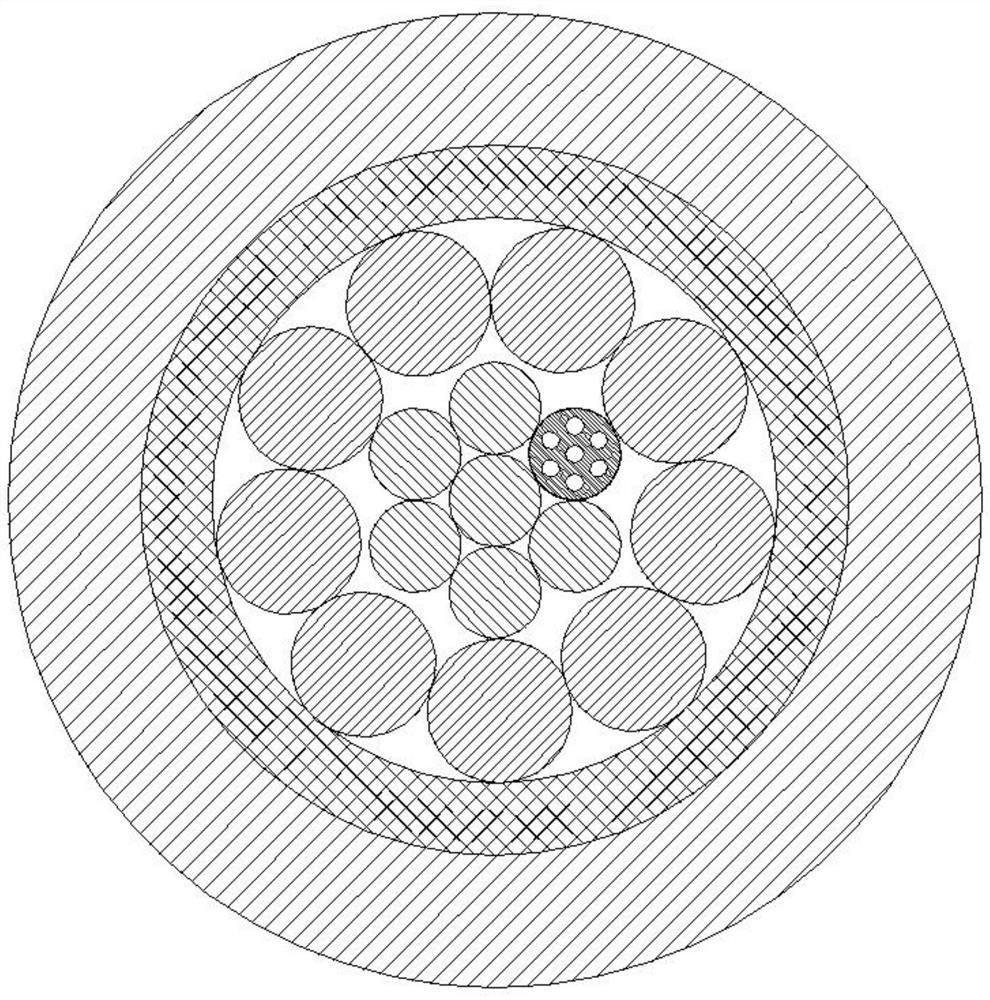

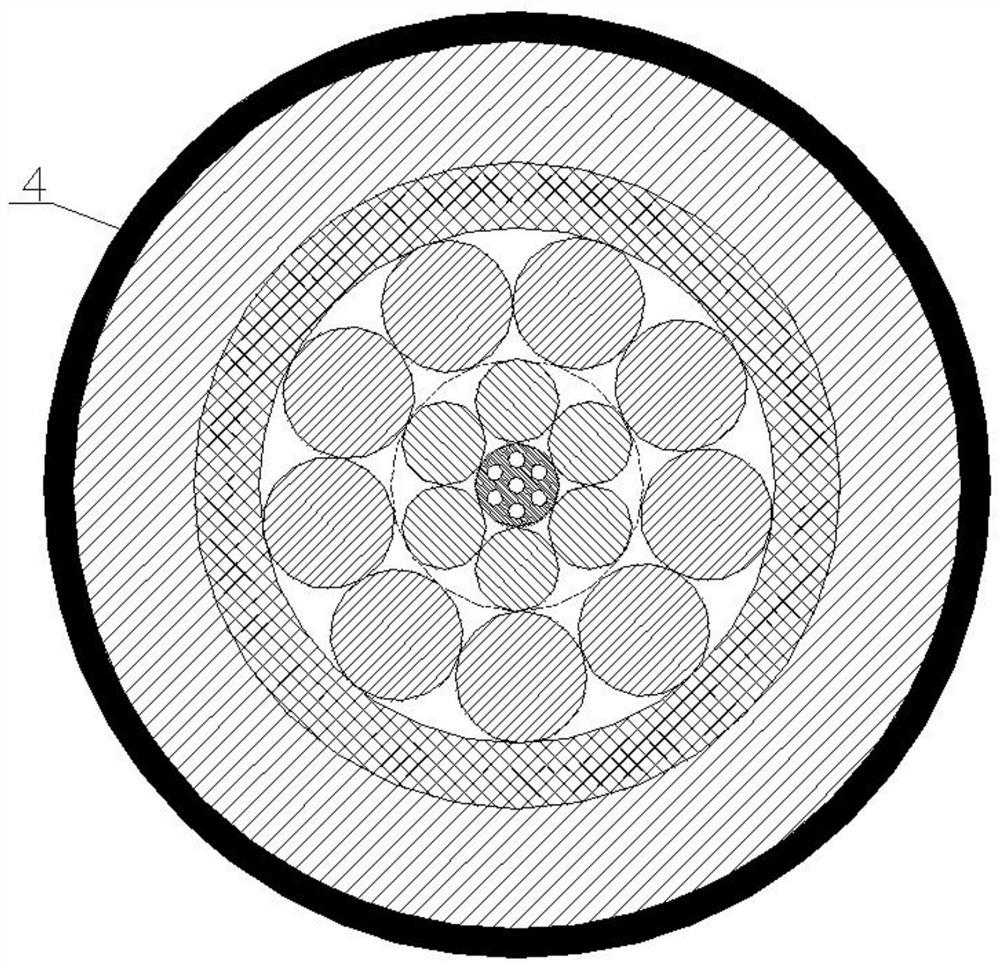

[0021] Below in conjunction with specific embodiment, content of the present invention is described in further detail, figure 1 It shows the structural schematic diagram of the first embodiment of the 10kv-35kv optical fiber composite overhead insulated cable with rated voltage in the present invention. Layer 4 is composed of several parts. Wherein, the internal strengthening core 1 includes an optical fiber unit 11 and an aluminum-clad steel wire layer 12 twisted with the optical fiber unit 11 . Along the extending direction of its length, the optical fiber unit 11 is always surrounded by the aluminum-clad steel wire layer 12 . The aluminum-clad steel wire layer 12 is composed of a plurality of aluminum-clad steel wires 121 uniformly distributed and twisted around the periphery of the optical fiber unit 11 , and twisted with the optical fiber unit 11 as the stranding center line. The conductive layer 2 is composed of a layer of aluminum wires 21 twisted around the periphery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com