Device for detecting leak rate of sealing ring

A technology of detection device and sealing ring, which is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement, etc., to achieve the effects of convenient processing, fast response speed and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

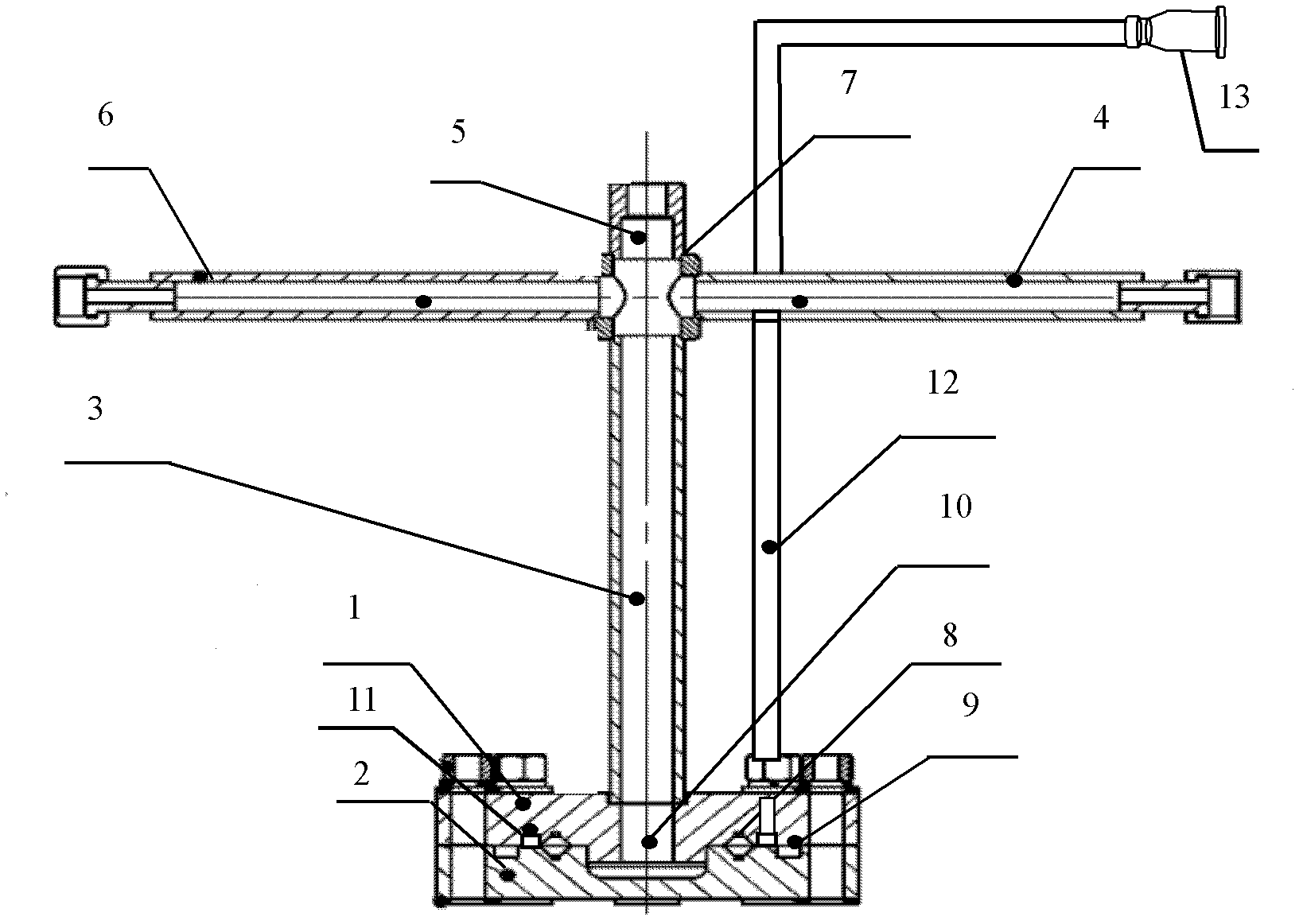

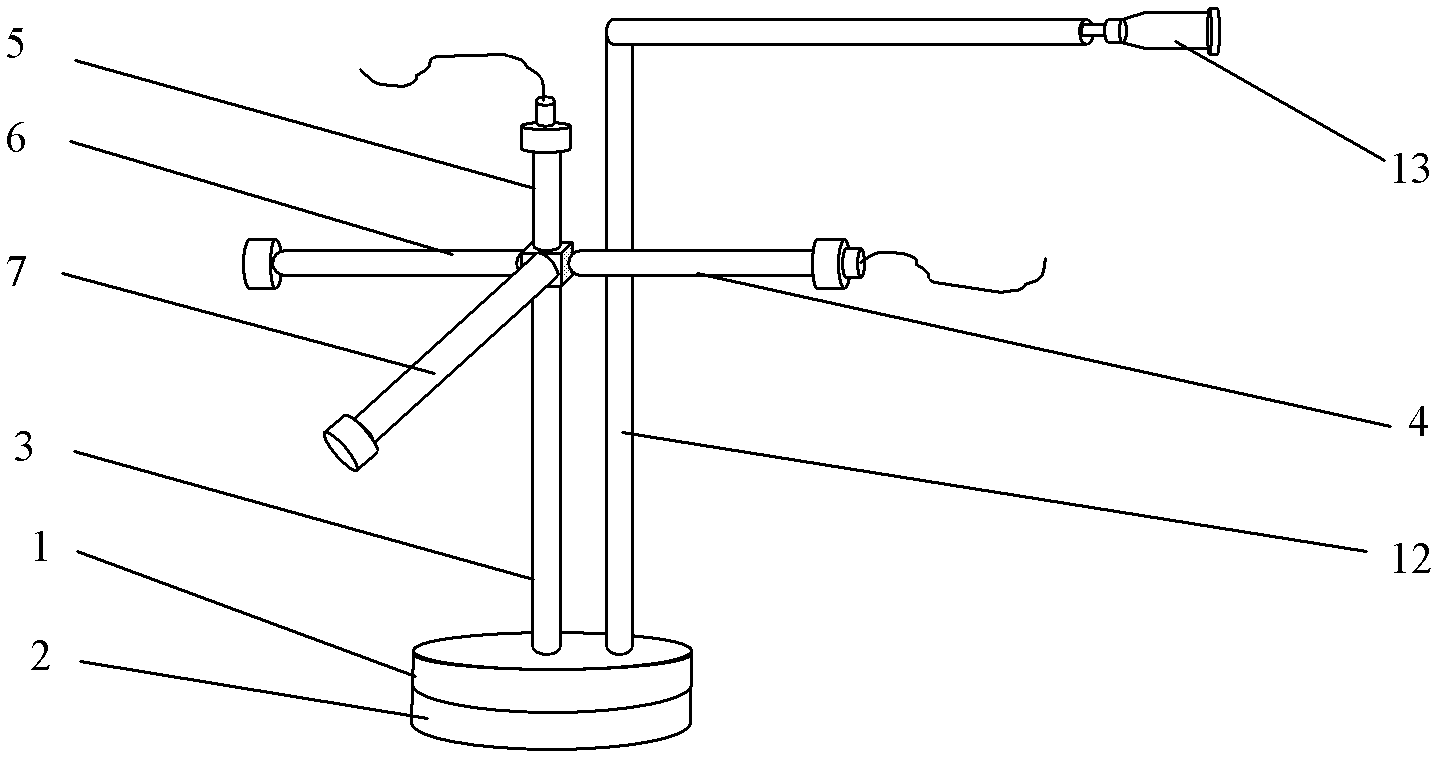

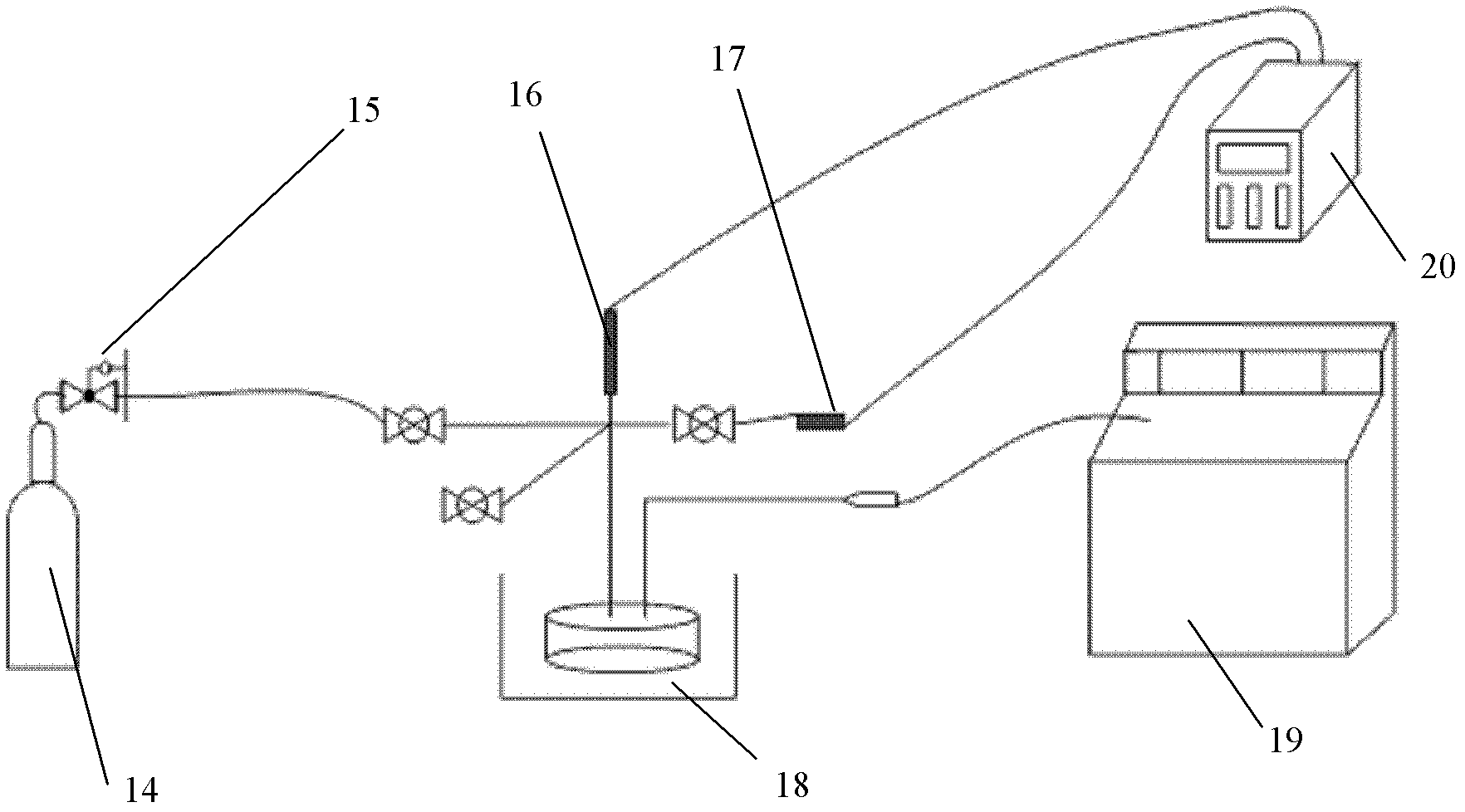

[0028] Such as figure 1 As shown, the sealing ring leakage rate detection device of the present invention includes a flange that is hermetically connected to the flange 2 and the flange cover 1, and the inner sealing groove 8 and the outer sealing groove 8 arranged between the flange 2 and the flange cover 1 The sealing groove, wherein the sealing ring to be tested is placed in the inner sealing groove 8, and the standard sealing ring is placed in the outer sealing groove 9. Open an annular leak detection groove 11 at the contact point between the flange plate 2 and the flange cover 1. The annular leak detection groove 11 can be opened on the flange plate 2 or on the flange cover 1. The circular leak detection groove 11 is set It is between the outer sealing groove 9 and the inner sealing groove 8, and is in non-leakage communication with the external leak detection pipe 12 for detection of leakage rate. A gas cavity 10 is opened at the center of the flange, and communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com