Conductive elastomer roller and manufacturing method thereof as well as image forming device

A conductive, body roll technology, which is applied to corona discharge devices, electrical recording processes using charge patterns, and equipment using electrical recording processes using charge patterns, etc. and other problems, to achieve the effect of improved surface performance, good electrification characteristics, and uniform distribution of electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

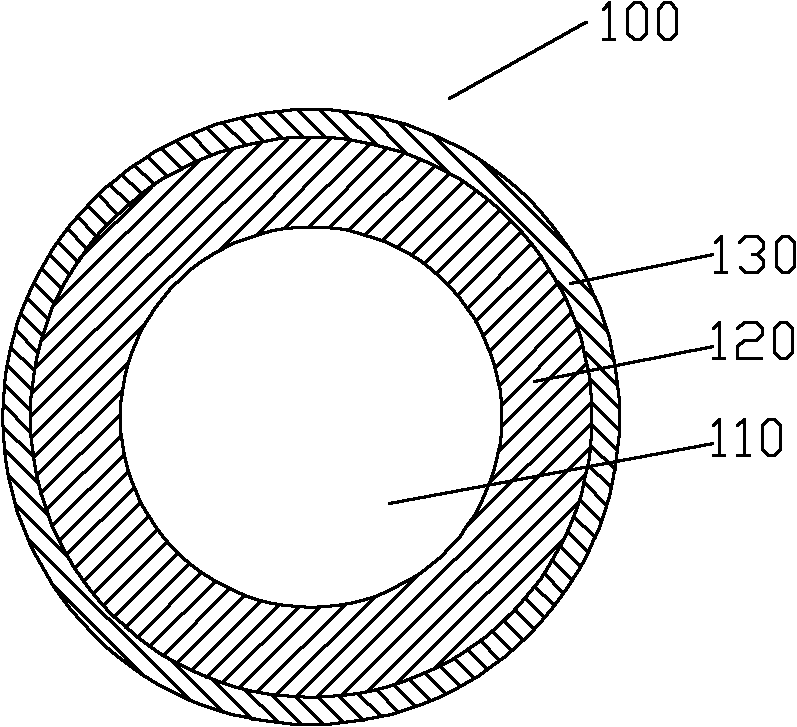

[0062] The preparation method of the elastic layer is generally to mix rubber with compounding agents, conductive materials, and fillers to form a conductive rubber mixture, and then vulcanize to form a conductive elastomer. The conductive elastic body is covered on the outside of the conductive shaft core 110 to form the conductive elastic layer 120 . There is no limitation on whether the obtained roller with the elastic layer is subjected to surface treatment, and it belongs to conventional technology in the art. For example, if surface treatment is carried out to described roller, can carry out grinding or other mechanical treatment to its surface, also can carry out chemical treatment to its surface, as carrying out photochemical modification or electrochemical modification, or coating adhesive layer etc. .

[0063]

[0064] The surface layer 130 is formed by coating the outer surface of the elastic layer with a coating resin solution containing two resin materials with...

Embodiment 1

[0089] With respect to the rubber and its compound used for forming the elastic layer, the "parts" described below refer to parts by mass.

[0090] Mix 100 parts of epichlorohydrin rubber (trade name: EPICHLOMER CG-102; produced by Dasao Co., Ltd., Japan) with 6.5 parts of zinc oxide, 1 part of stearic acid, and 30 parts of activated calcium carbonate (particle size: 1250 mesh; Nanjing Omiya Fine Chemicals Co., Ltd. Co., Ltd.), 8 parts of carbon black (trade name: VULCAN XC72; produced by Cabot Corporation) are mixed evenly in the mixing equipment, and then add 0.5 parts of sulfur, 2 parts of dicumyl peroxide (trade name: DCP-40C ; Produced by Sinopec Shanghai Gaoqiao Petrochemical Company) and mixed evenly to obtain an unvulcanized conductive rubber mixture.

[0091] The unvulcanized conductive rubber mixture was coated on the outside of a conductive shaft core with an outer diameter of 8 mm, and then placed in a cylindrical mold with an inner diameter of 15 mm, and the two w...

Embodiment 2

[0096] A developing roller was obtained in the same manner as in Example 1, except that an acrylic resin (trade name: TCA-837B-1; manufactured by Taichang Resin Co., Ltd.) was used as the first resin. The resulting developing roller had a surface layer thickness of 12 micrometers and a surface roughness Rz of 5-7 micrometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com