Combined powder removing and paper clipping machine and using method

An all-in-one, combined technology, applied in the fields of electrography, optics, instruments, etc., can solve the problems of high time and manpower consumption, low production efficiency, hidden quality problems, etc., to save printers and computers, save time and manpower, The effect of saving turnaround time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

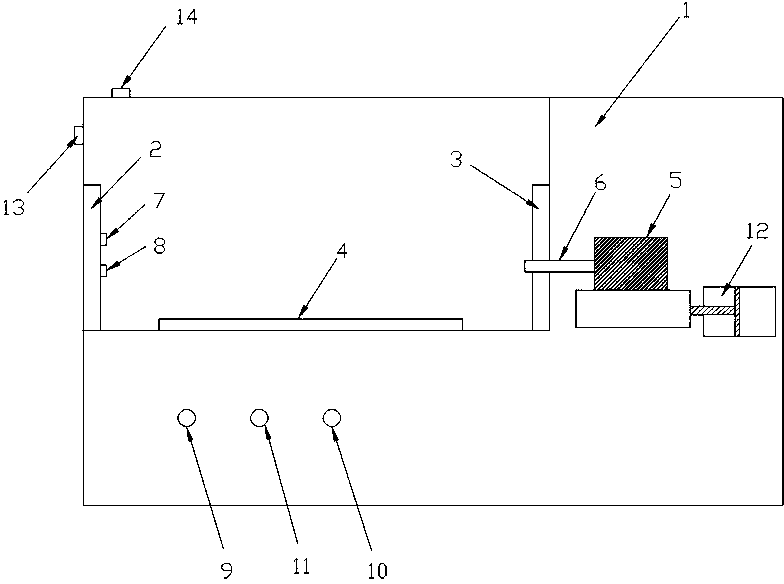

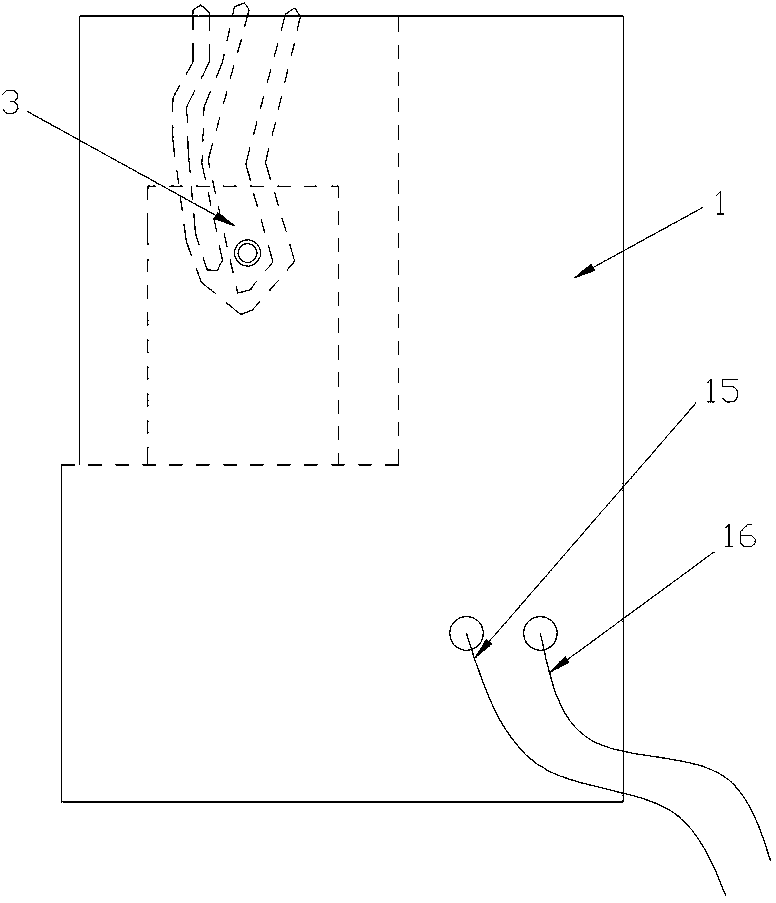

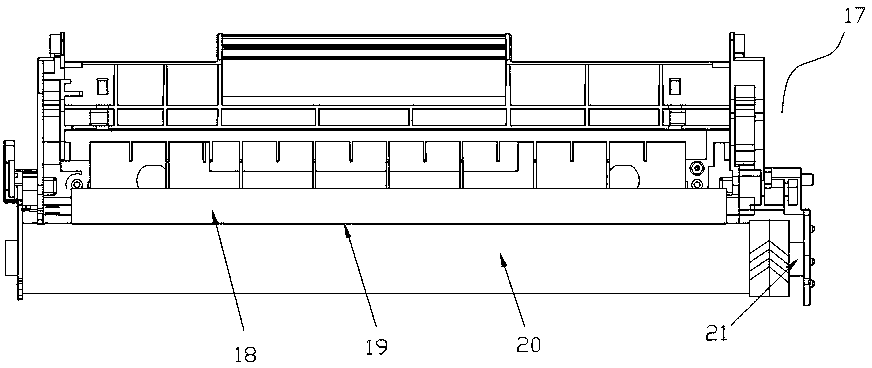

[0026] Such as figure 1 , figure 2 As shown, the combined machine for powder removal and paper clamping according to the present invention includes a machine base 1 and an internal controller, and the first toner cartridge clamping position 2 and the second toner cartridge are respectively installed on both sides of the machine base 1 Cartridge clamping position 3, photosensitive drum conductive contact 7 and magnetic roller conductive contact 8 are provided on the first toner cartridge clamping position 2, and the photosensitive drum conductive contact 7 and magnetic roller conductive contact 8 are respectively connected with The photosensitive drum on the toner cartridge is in contact with the conductive sheet on the end surface of the magnetic roller; a drive motor 5 is also arranged in the base 1, and the base 1 controls the forward rotation switch 9 and reverse rotation of the drive motor 5. switch 10 and stop switch 11, the rotating shaft 6 of the drive motor 5 extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com