Terminal for connecting wires to printed circuit boards

A printed circuit board and cable technology, applied in the directions of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problem that the cable cannot be reliably maintained, and achieve the effect of optimizing the maximum utilization, optimizing the elasticity, and optimizing the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

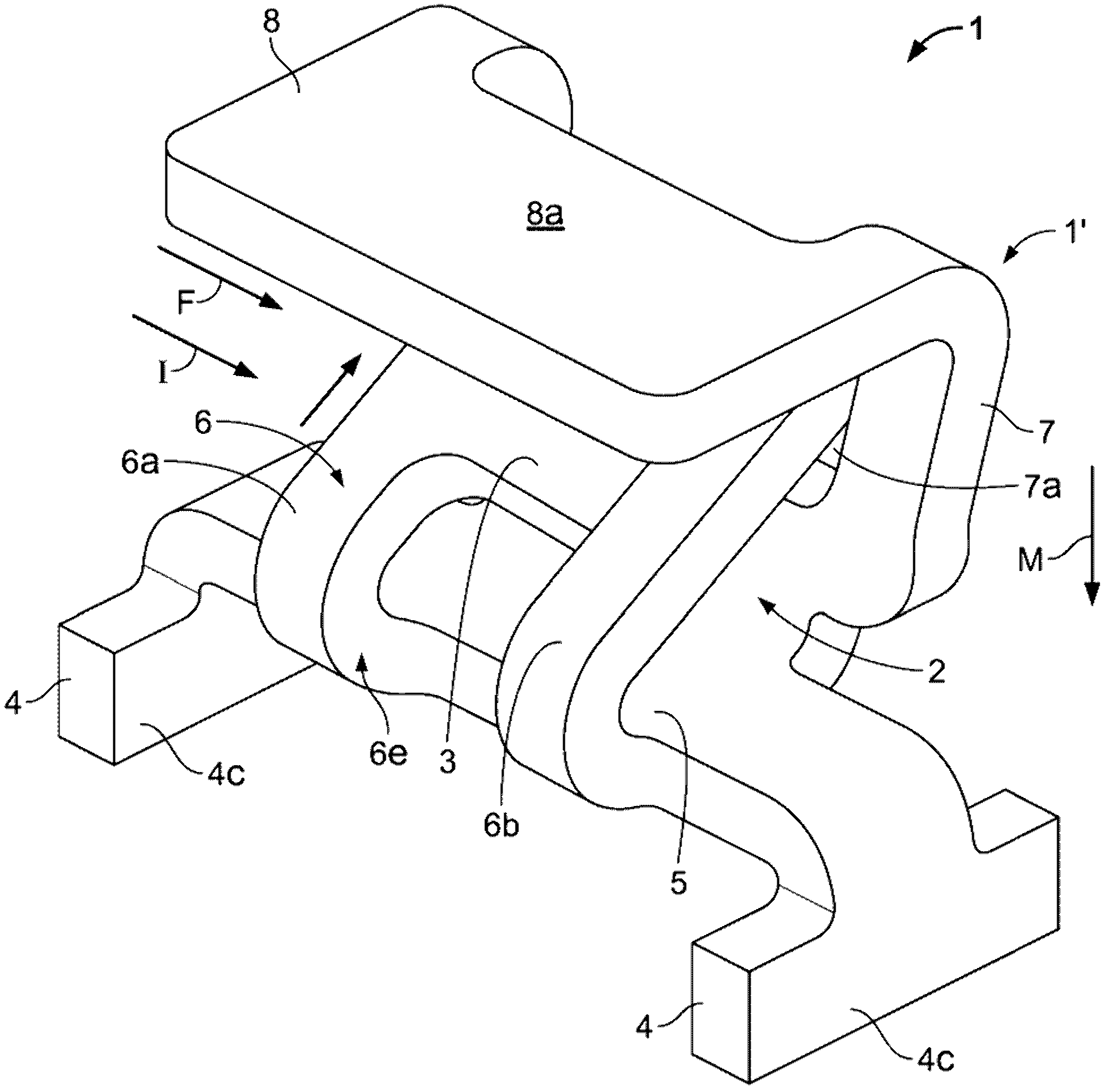

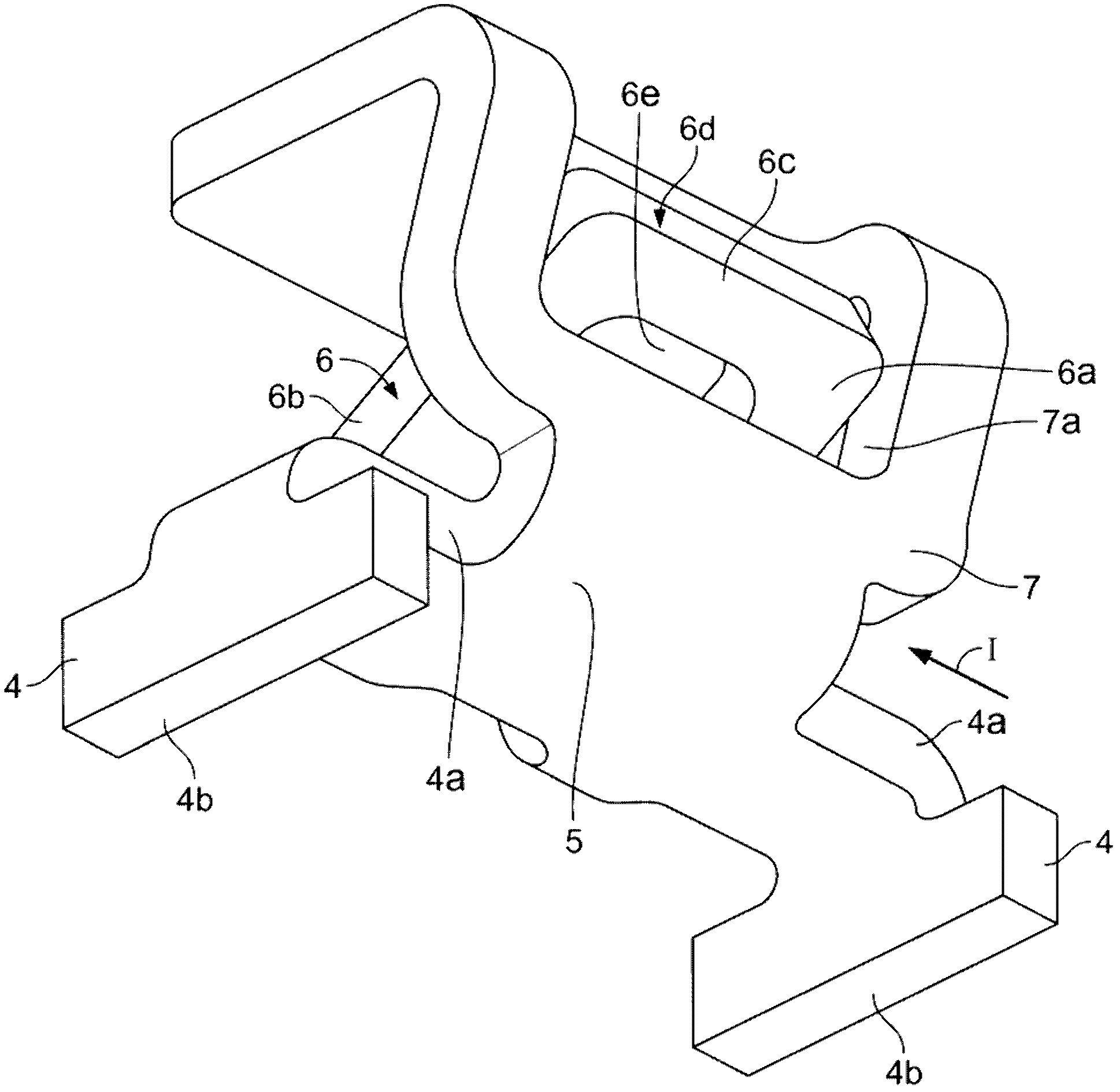

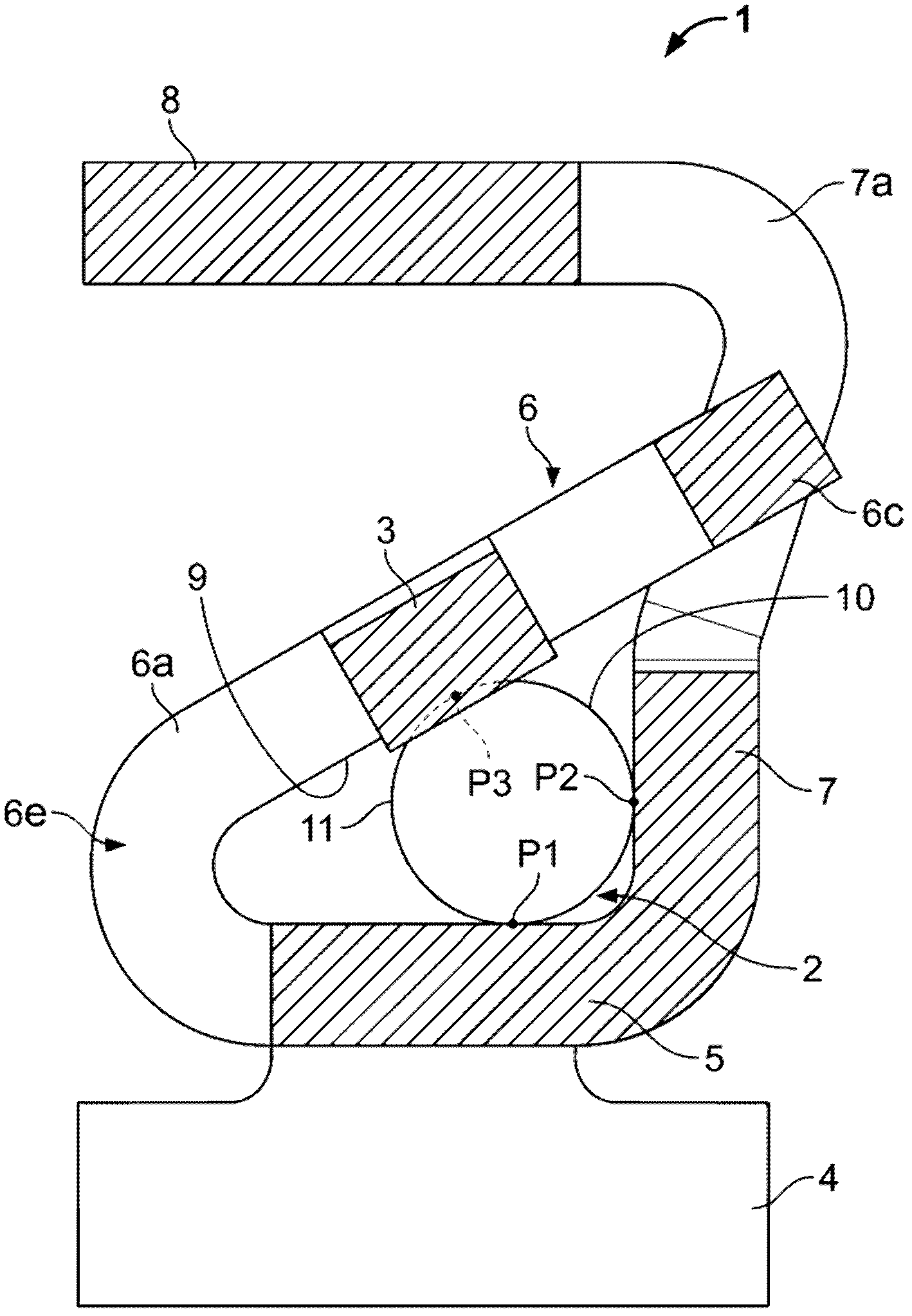

[0035] First, refer to figure 1 The structure of the terminal 1 configured according to the present invention is described.

[0036]The terminal 1 is configured as a poke-in terminal, that is, a cable can be electrically connected as well as mechanically connected to the terminal by poking the cable into the terminal 1 . The terminals are formed by a thin metal plate 1'. The sheet metal can be made of any type of alloy, preferably a copper alloy.

[0037] To receive at least the contact portion of the cable, the terminal comprises a cable receiver 2 . The cable receiver 2 is provided with a cable retainer 3 which is pressed onto the cable in the fitted state of the terminal 1 of the cable receiver 2 receiving the cable to overcome the action on the cable or the cable. external traction while maintaining the cable. The cable holder 3 protrudes from the holder spring 6 . The cable retainer 3 and the retainer spring 6 are arranged in series so that when the cable 11 is pushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com