High speed electric spindle supported by all-permanent magnet bearing

A technology of high-speed electric spindle and permanent magnetic bearing, which is applied in the direction of casing/housing/support, magnetic attraction or thrust holding device, electrical components, etc., and can solve the problems that cannot be widely applied, complex system, high cost, etc. , to achieve the effect of eliminating the need for lubrication and sealing devices, strong environmental adaptability, and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

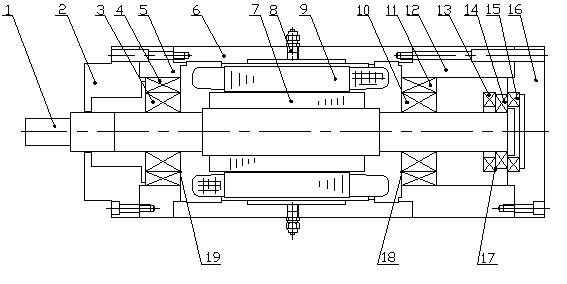

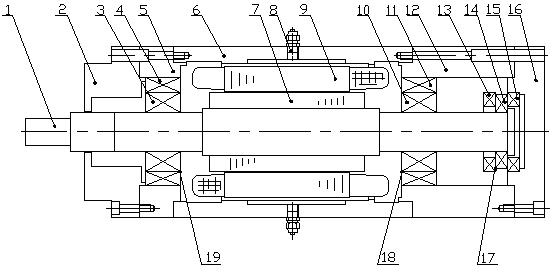

[0025] Preferred embodiments of the present invention are described as follows in conjunction with the accompanying drawings:

[0026] This example is: see figure 1 , the high-speed electric spindle supported by full permanent magnetic bearings, including motor stator (9), motor rotor (7), rotating shaft (1), casing (6), front cover (2), front bearing seat (5), rear bearing Seat (12), back cover (16) and supporting system etc. The support system includes: two pairs of radial permanent magnetic bearings (moving magnetic rings 3 and 10, static magnetic rings 4 and 11) as radial support bearings, two-way permanent magnetic thrust bearings (static magnetic rings 13, 15 and moving magnetic rings 14) As an axial support bearing. The two pairs of radial permanent magnetic bearings (moving magnetic rings 3 and 10, static magnetic rings 4 and 11) are installed on both sides of the motor rotor 8, and the two-way permanent magnetic thrust bearings (static magnetic rings 13, 15 and dyna...

Embodiment 2

[0028] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0029] see figure 1 The motor stator (9) and the motor rotor (7) installed in the electric spindle are placed in the cavity in the housing (6), and the motor stator (9) is fixedly connected to the inner wall of the housing (6). A cooling water channel (8) is arranged on the casing (6) to connect to the cooling system to cool the outside of the built-in motor stator (9).

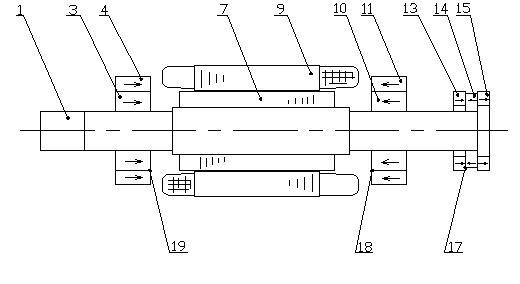

[0030] The supporting system principle and supporting system layout of the rotating shaft (1) can be found in figure 2 , the magnetic pole direction of the moving magnetic ring (3) and the static magnetic ring (4) in the radial permanent magnetic bearing (19) at the left end are the same, and the moving magnetic ring (10) and the static magnetic ring (11) in the radial permanent magnetic bearing (18) at the right end ) The magnetic poles have the same direction, and they are all repulsive radial permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com