Pressure sensor and method of adjusting the same

A technology of pressure sensor and adjustment method, which is applied in the direction of converting sensor output, measuring fluid pressure, measuring fluid pressure through electromagnetic components, etc., to achieve the effect of simple range adjustment method, cost reduction, and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

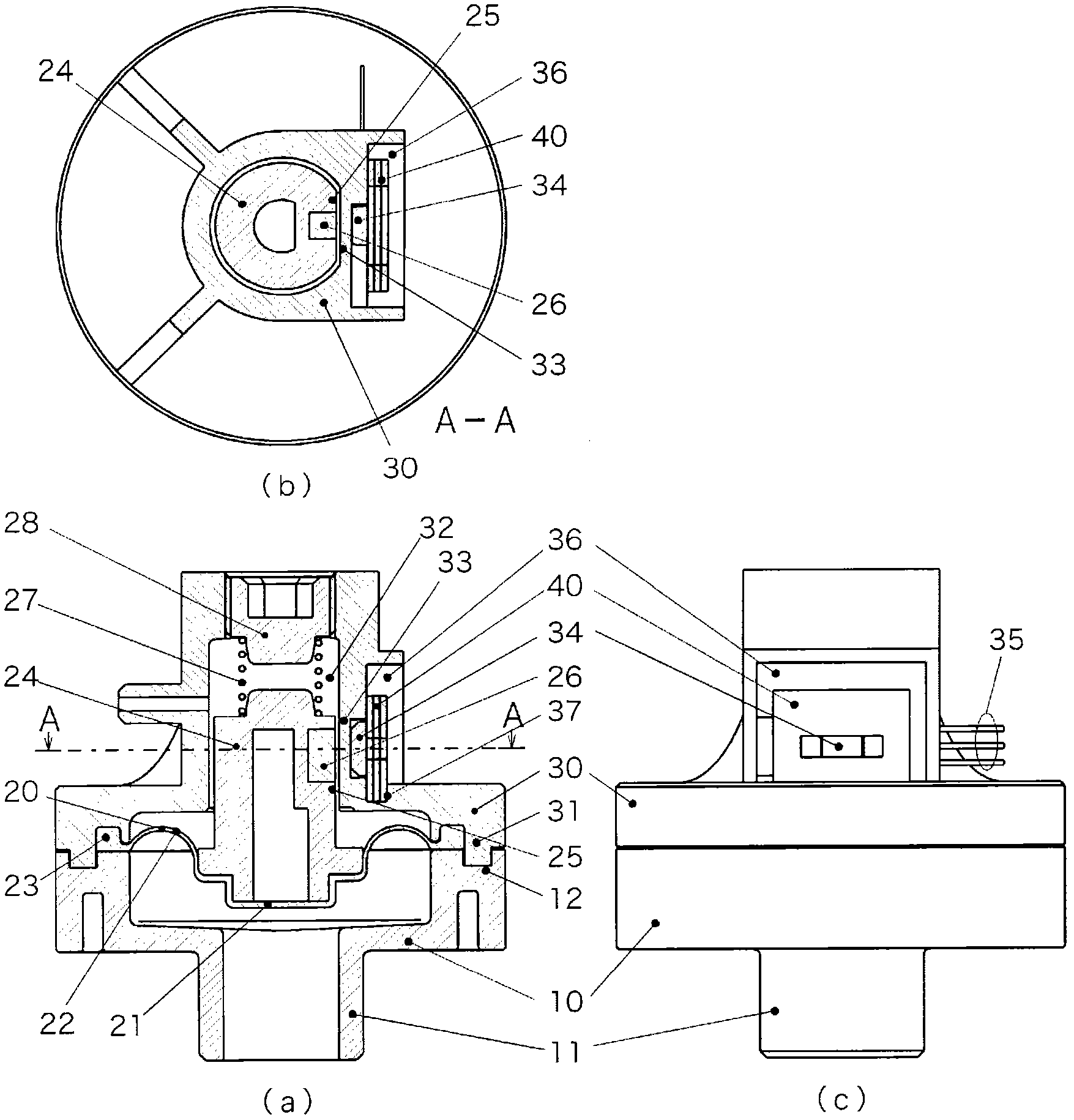

[0047] figure 1 It is a figure which shows the structure of the 1st Embodiment of the pressure sensor of this invention, (a) is a cross-sectional view of the pressure sensor of this embodiment, (b) is A-A line cross-sectional view of (a), (c) is a side view. Furthermore, the pressure sensor of the present invention is used, for example, as a micro-pressure sensor for a rice cooker.

[0048] In this figure, 10 is a joint body, 20 is a diaphragm, and 30 is an upper body. At the center of the bottom surface of the joint body 10 is provided a joint portion 11 having an inlet for introducing a fluid to be measured, and a stepped portion 12 is formed on the upper surface of the joint body 10 . The above-mentioned diaphragm 20 is made of, for example, high-hardness silicone rubber, and a pressure-receiving plate support portion 21 is formed at the center, and a ring-shaped thick-walled elastic force applying portion 22 is formed around it, and a flange portion is formed on the perip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com