Automatic multi-claw hydraulic returning and clamping chuck and use method thereof

A clamping chuck and hydraulic technology, applied in the direction of chucks, etc., can solve the problems of low efficiency, inapplicability to automatic production, high processing waste rate, etc., and achieve the effects of uniform force, high processing yield, and easy fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

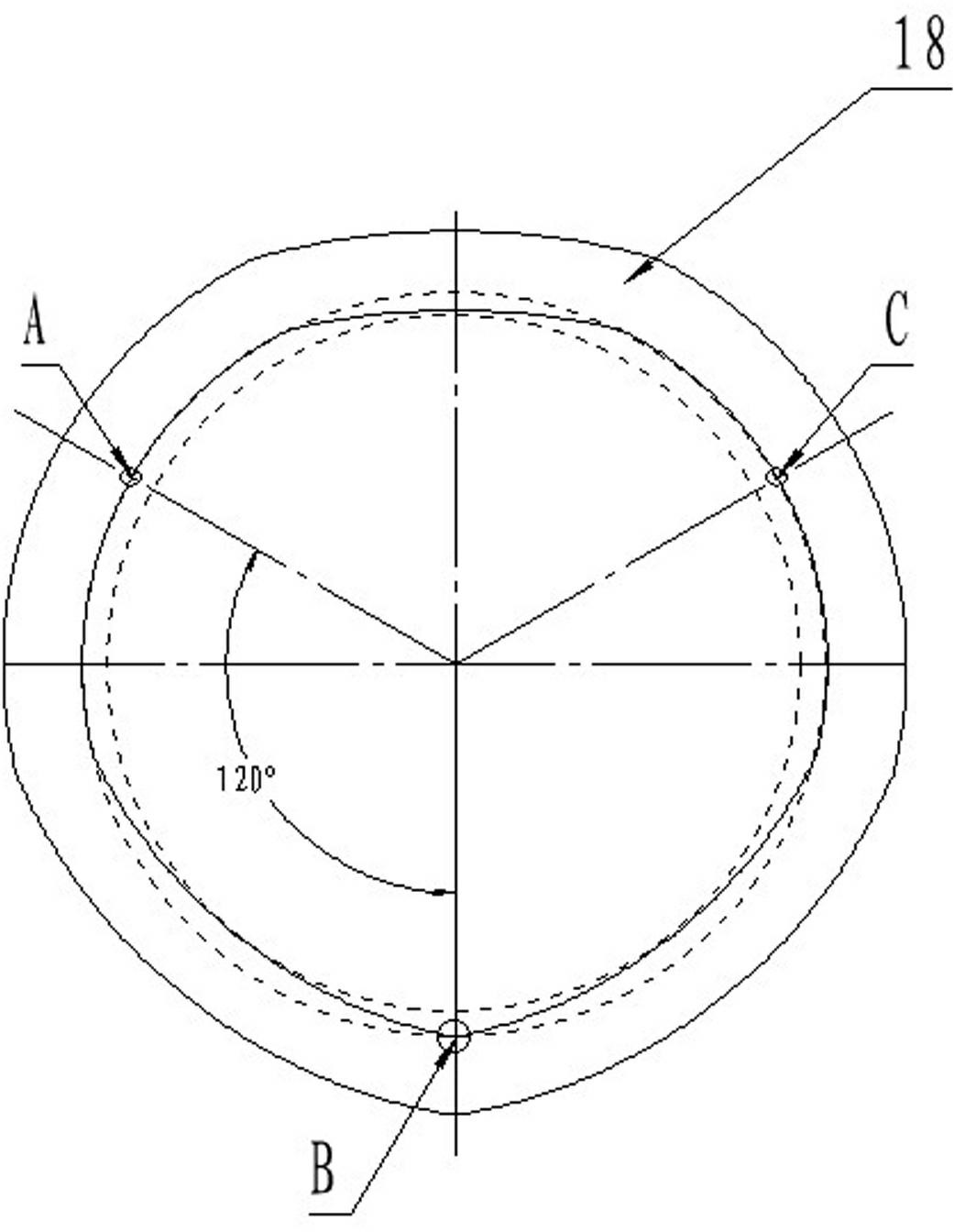

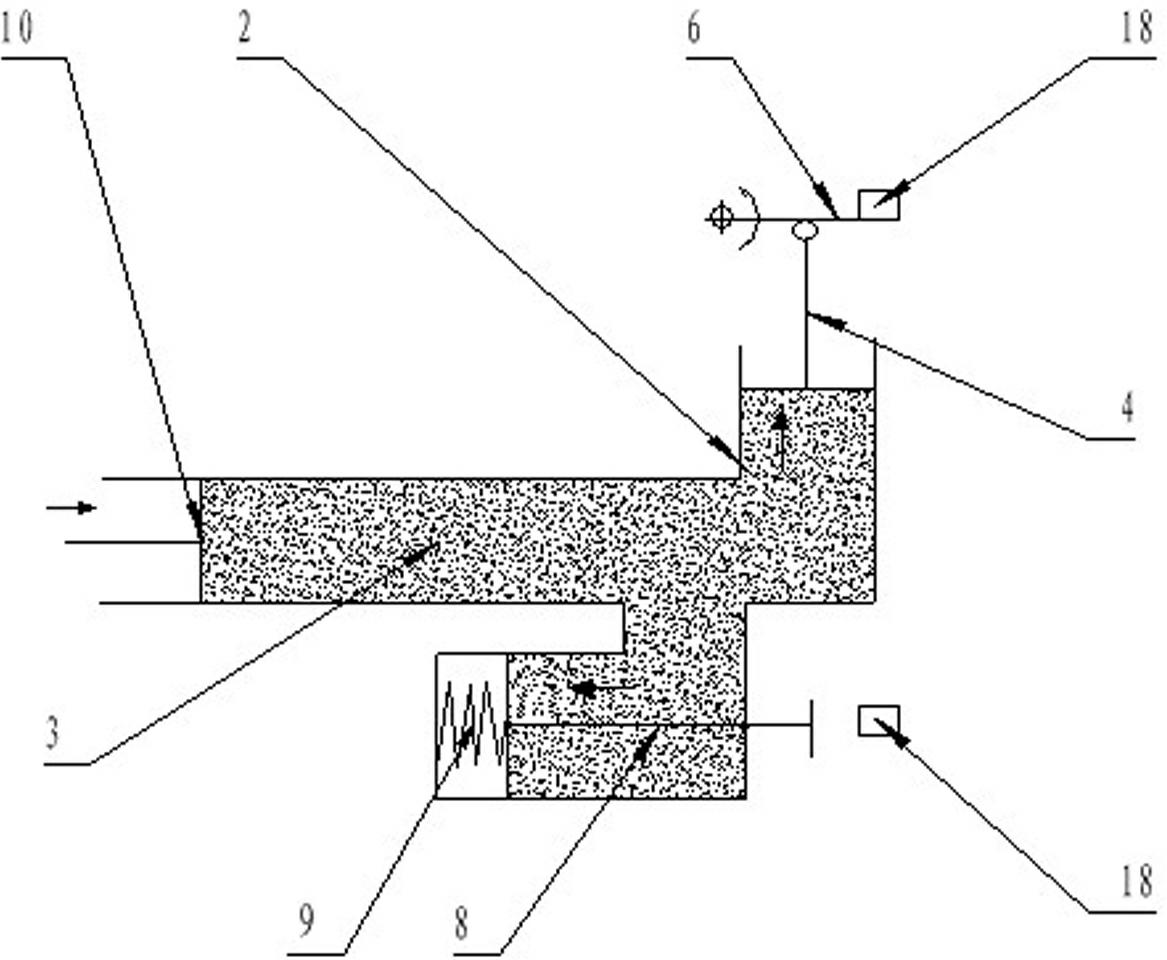

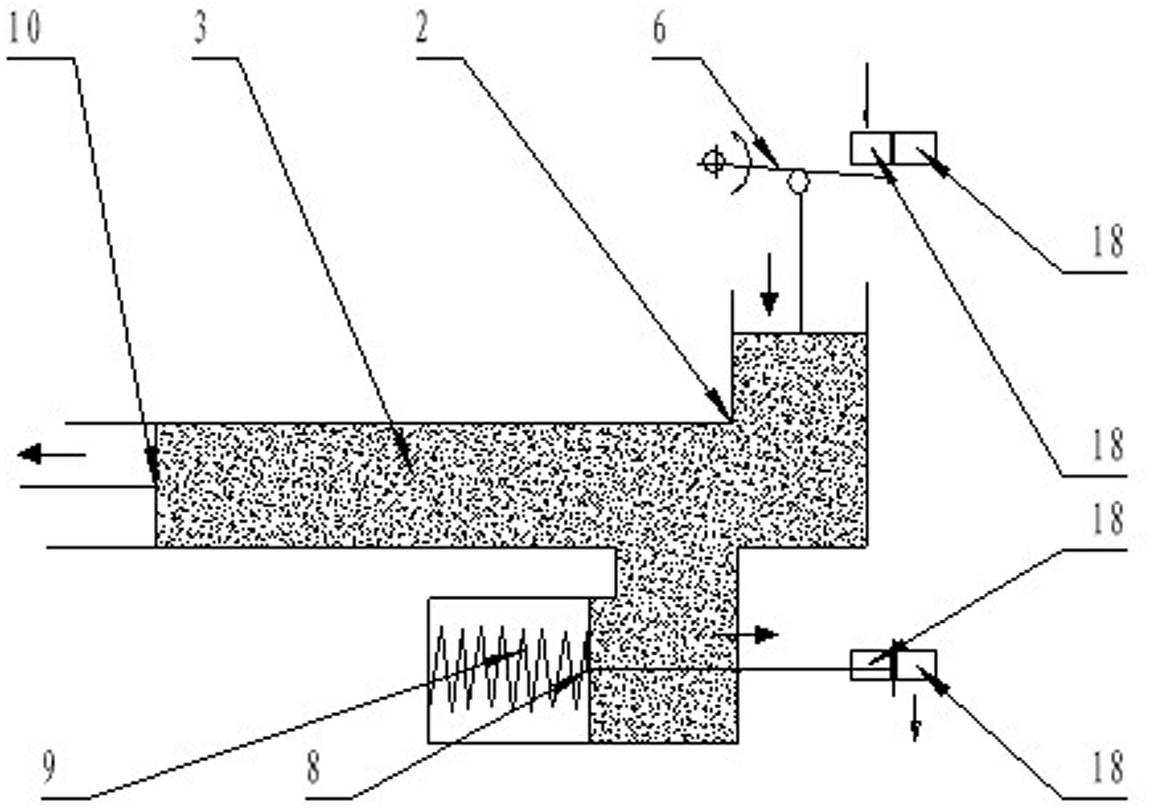

[0029] The multi-jaw hydraulic automatic material return clamping chuck of the present invention and its use method will be further described below in conjunction with the accompanying drawings.

[0030] Such as Figure 4 , Figure 5 , Figure 6 It can be seen that the multi-claw hydraulic automatic material return clamping chuck of the present invention includes a rotary cylinder 1 and a chuck body 2. The inner cavity of the chuck body 2 is provided with a connector oil chamber 3, and the chuck body 2 is arranged along its radial direction. A plurality of clamping plunger chambers 40 communicating with the oil chamber 3 of the connector are provided, and each clamping plunger chamber 40 is provided with a clamping plunger 4 .

[0031] The clamp body 2 is also provided with rocker-arm claws 6 matching the clamping plunger 4 through a plurality of pin shafts 5, and claw springs are respectively arranged between the multiple rocker-type claws 6 and the clamp body 2. 7. The fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com