Rotor blade adopting flat design

A technology for rotor blades and blades, which is applied in the directions of rotorcraft, motor vehicles, and aircraft, can solve the problems of low degree of automation, a lot of manual work, and cost concentration, and achieves low manufacturing cost, small thickness, light weight, and large bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

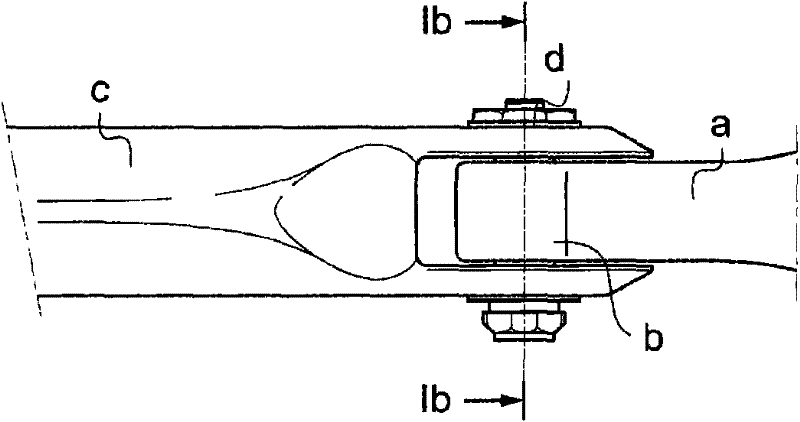

[0018] Figure 1 shows the prior art. To this end, FIG. 1 a shows a part of the rotor system at the point where the rotor blades are connected. The immediately recognizable blade part a transitions into the connecting part b in which the ring connection is formed. This forms the interface with the drive c, which surrounds the connection part b in a fork shape. Bolt d connects device c to connection part b.

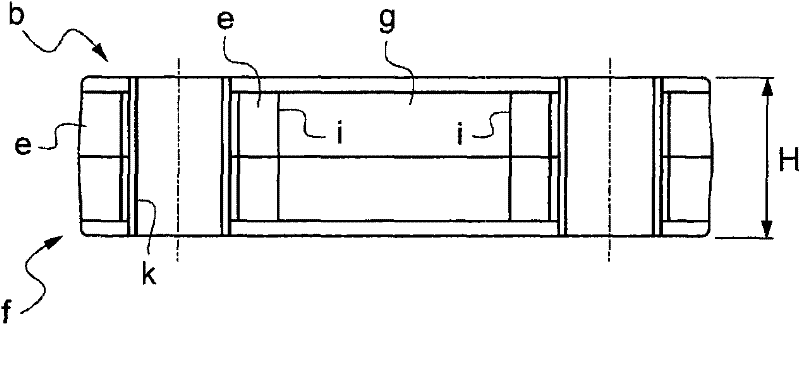

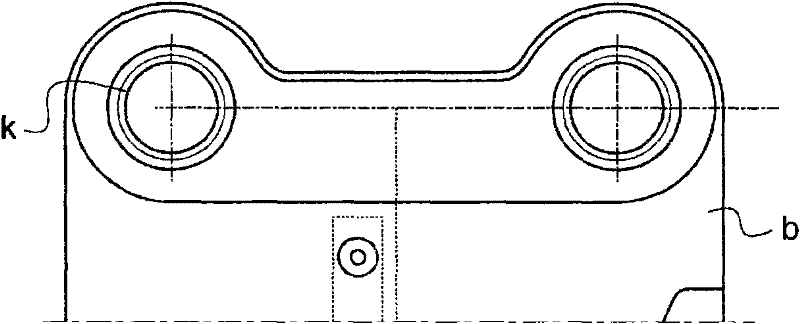

[0019] FIG. 1 b shows a sectional view according to FIG. 1 a in the region of the bolt d. The blade section consists of loops of glass fibers called rovings. A roving e is wound into a loop f around a wound fiber lining k. In the sectional view of FIG. 1 b , the plane of the roving e therefore extends parallel to the axial direction of the bolt d and lining k or perpendicular to the plane of extension of the connection part b. They form a "standing" loop f which imparts a height H to the connecting portion b. Between them is a central space g filled with horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com