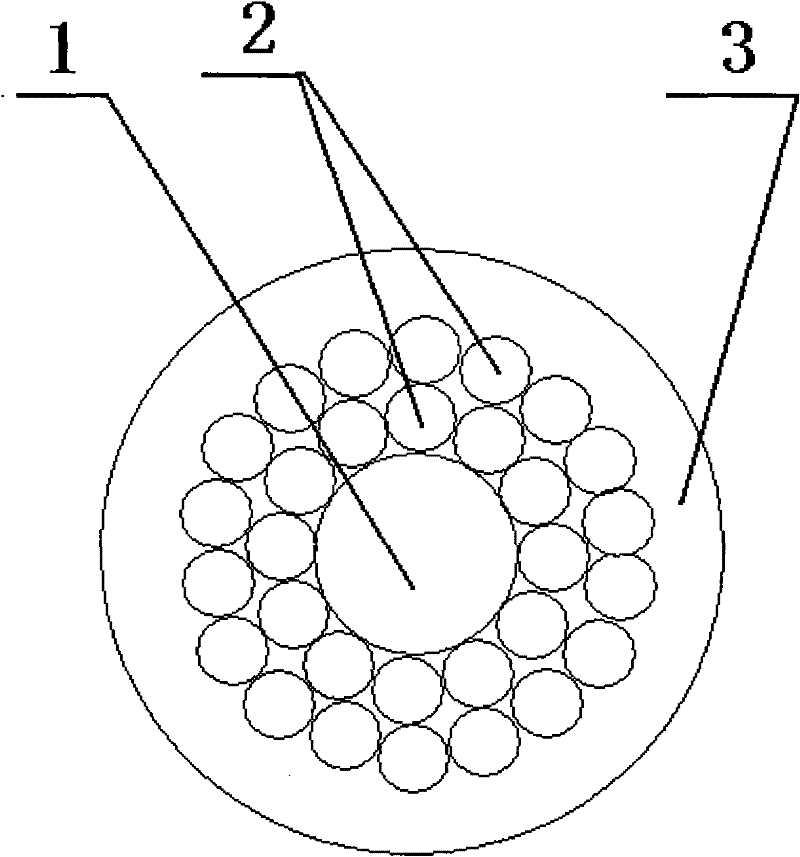

Plastic coated steel wire rope with thirty one wires

A steel wire rope and steel wire technology, applied in the field of steel wire rope, can solve the problems of steel wire rope performance differences, easy peeling of the surface layer, easy corrosion and rust, etc., and achieve the effect of compact structure, good wear resistance and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0014] according to figure 1 As shown, a thirty-one-one plastic-coated steel wire rope of the present invention includes a steel wire rope. The steel wire rope is twisted by stainless steel wires, and the steel wires are in point contact. The steel wire rope is twisted by thirty-one steel wires once The center of the steel wire rope is a steel wire 1, and its periphery is wrapped with twelve and eighteen two-layer steel wires 2 in turn, and the diameters of the thirty steel wires 2 wrapped around the center steel wire 1 are the same; The diameter of the central steel wire 1 is greater than the diameter of the thirty steel wires 2 wrapped around it; the twisted steel wire rope is provided with a nylon plastic-coated layer 3; the torque of the steel wire rope is 9; The cross-section of the thirty one plastic-coated steel wire rope is circular. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com