Gas floating cushion for gas floating bearing

A technology of air bearings and air bearings, applied in the field of air bearings, which can solve the problems of no flexible connection, adjustment, and inability to adjust the thickness of the air film, so as to increase the hardness and wear resistance and reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

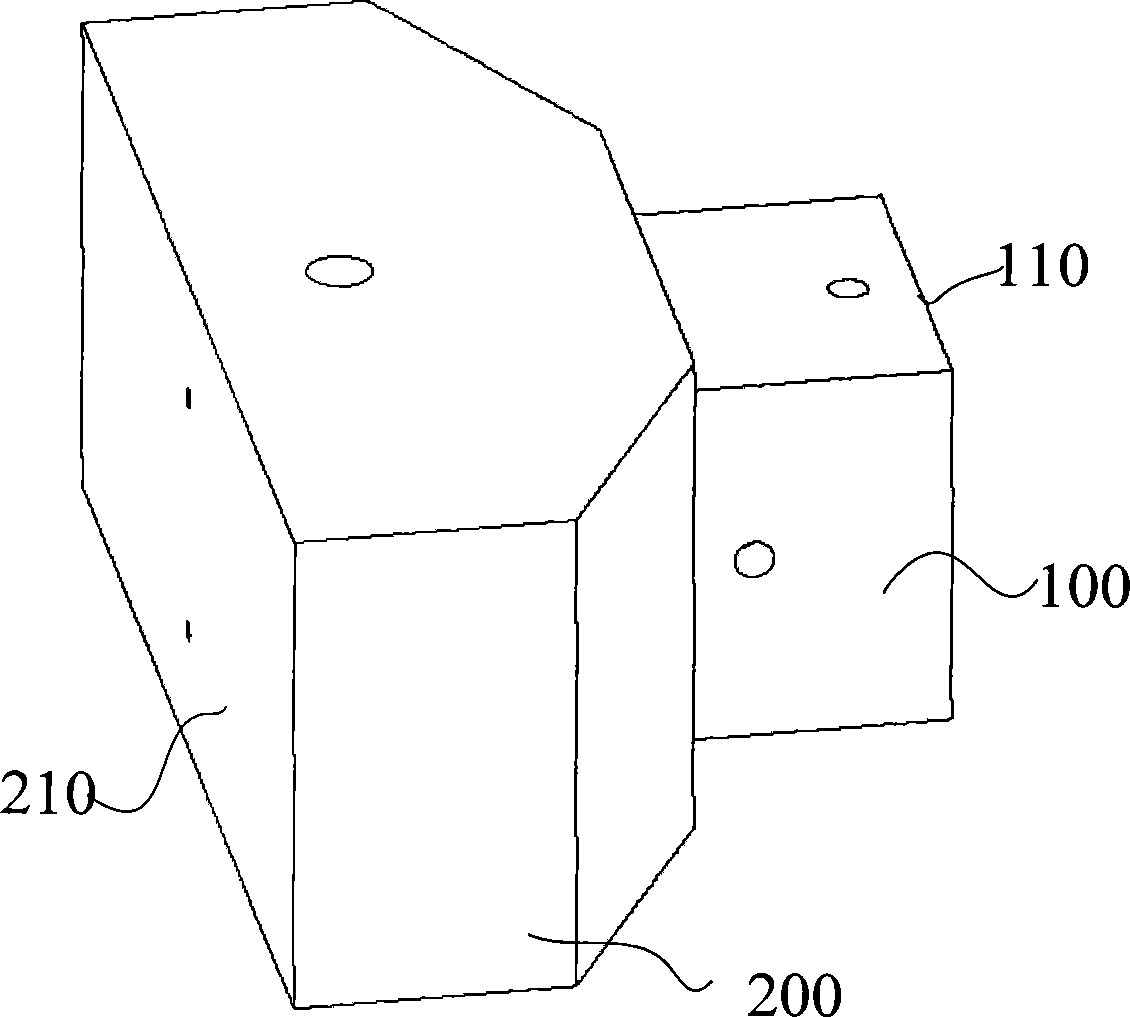

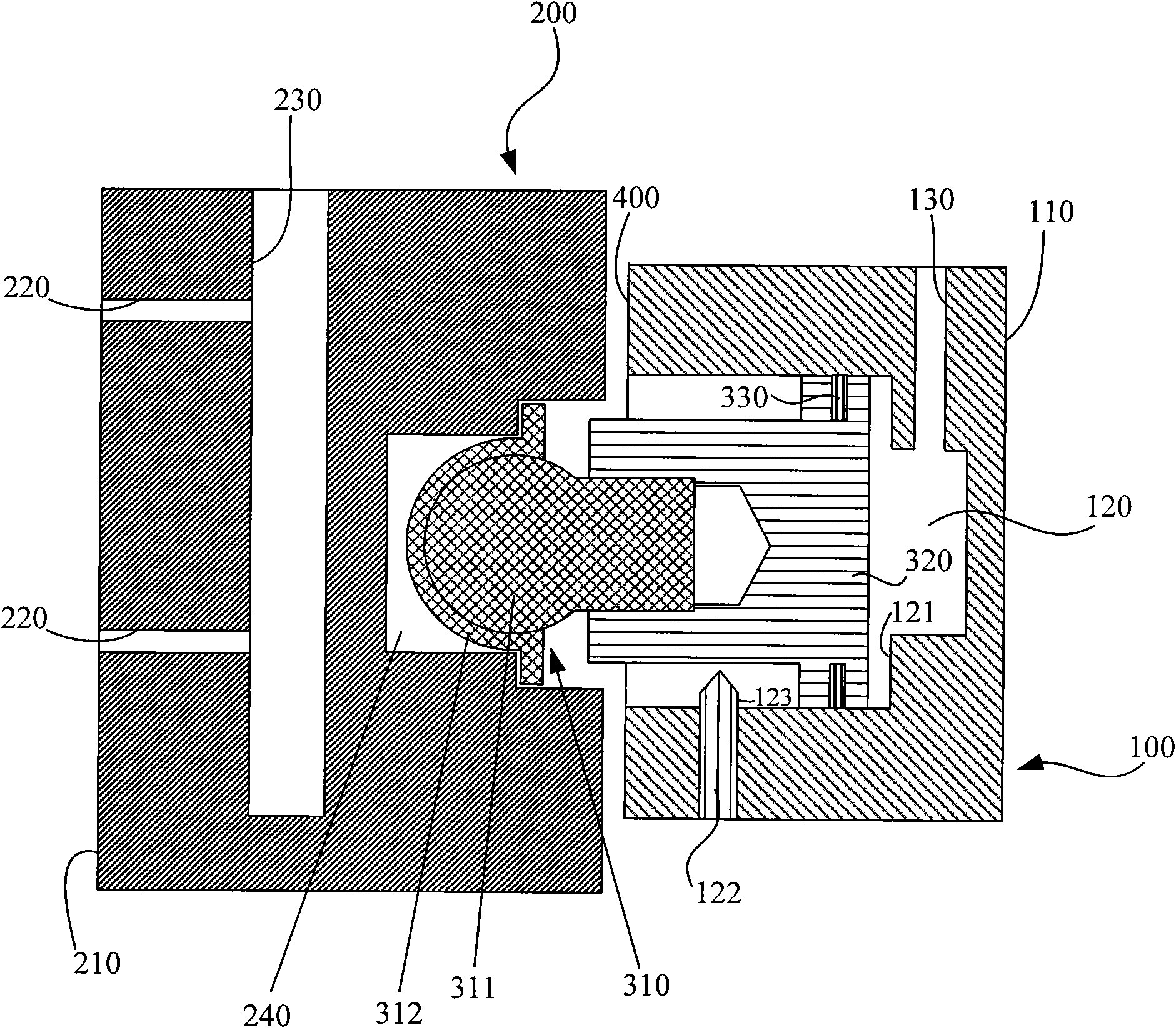

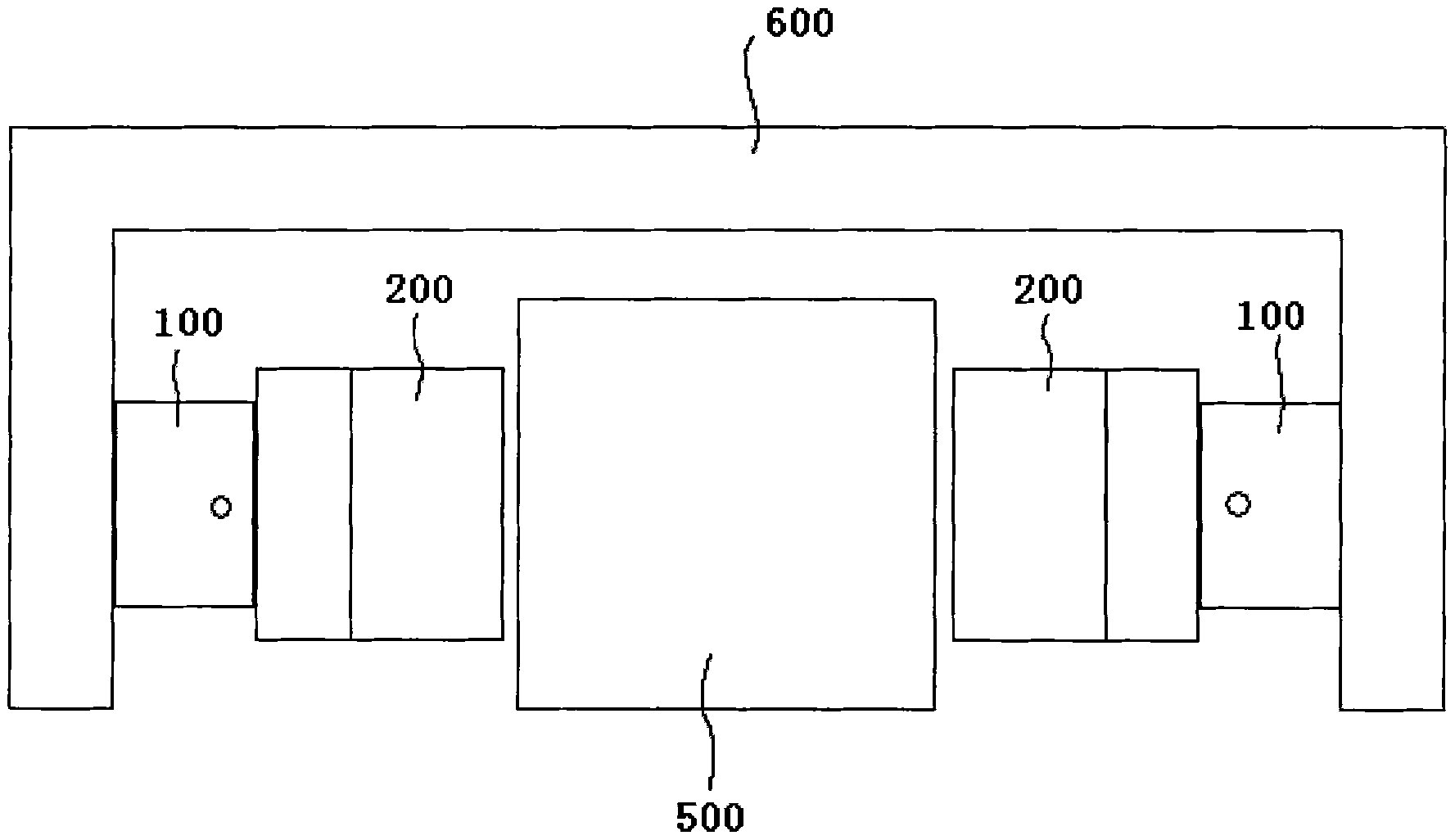

[0029] The following will combine Figure 1 ~ Figure 3 The air bearing pad for air bearing of the present invention will be further described in detail.

[0030] The air bearing pad used in the air bearing of the present invention includes an upper support, a lower support and a connecting part;

[0031] One end of the connecting part is movably connected with the upper support, and the connecting part can move within a certain range relative to the upper support;

[0032] The other end of the connecting member is connected to one end of the lower support, and the end surface of the other end of the lower support is an air floating surface;

[0033] The movement of the connecting part relative to the upper support drives the movement of the lower support, thereby changing the distance between the air bearing surface and the guide rail.

[0034] The air bearing pad for air bearing of the present invention is now described in detail with a preferred embodiment:

[0035] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com