Pad conveying mechanism of combined grinder of automobile brake pad

A brake pad and pad feeding technology, applied in the field of the disc feeding mechanism of the combined grinder, can solve the problems of the variation of the feeding speed, the inconsistent feeding force, and the non-moving pads, etc., so as to achieve continuous transportation speed, improve processing quality, and balance the driving force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

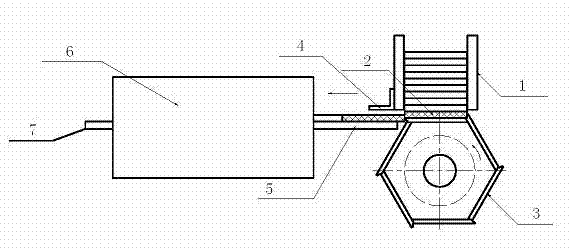

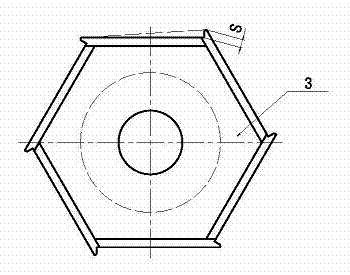

[0014] figure 1 Among them, the film feeding ratchet 3 is placed at the film outlet of the film loading box 1. One side of the sheet-feeding rotation direction of the ratchet wheel 3 is provided with a guide rail 5, and the guide rail 5 stretches into the combination mill 6, and the combination mill 6 outlets are provided with a joint place 7. One side of the film outlet of the loading box 1 is equipped with a pressing plate 4 forming a film feeding channel with the guide rail 5 . The slice sending ratchet 3 is connected with the power system, and the shape of the end surface of the slice sending ratchet 3 is a regular polygon.

[0015] figure 2 Among them, the shape of the end surface of the sheet-feeding ratchet 3 is a regular polygon, that is, the rear end of the previous ratchet is moved toward the center by S (S is 10-20 mm), so that the front end of the latter ratchet is higher than the previous ratchet. The rear end position of tooth is 10~20 millimeters, is 10~20 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com