Transfer device with magnetic field drying device

A technology of transfer device and transfer layer, applied in transfer printing, rotary printing machine, general parts of printing machinery, etc., can solve the problems of strengthening finishing quality, unevenness, damage, etc., and achieve the effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

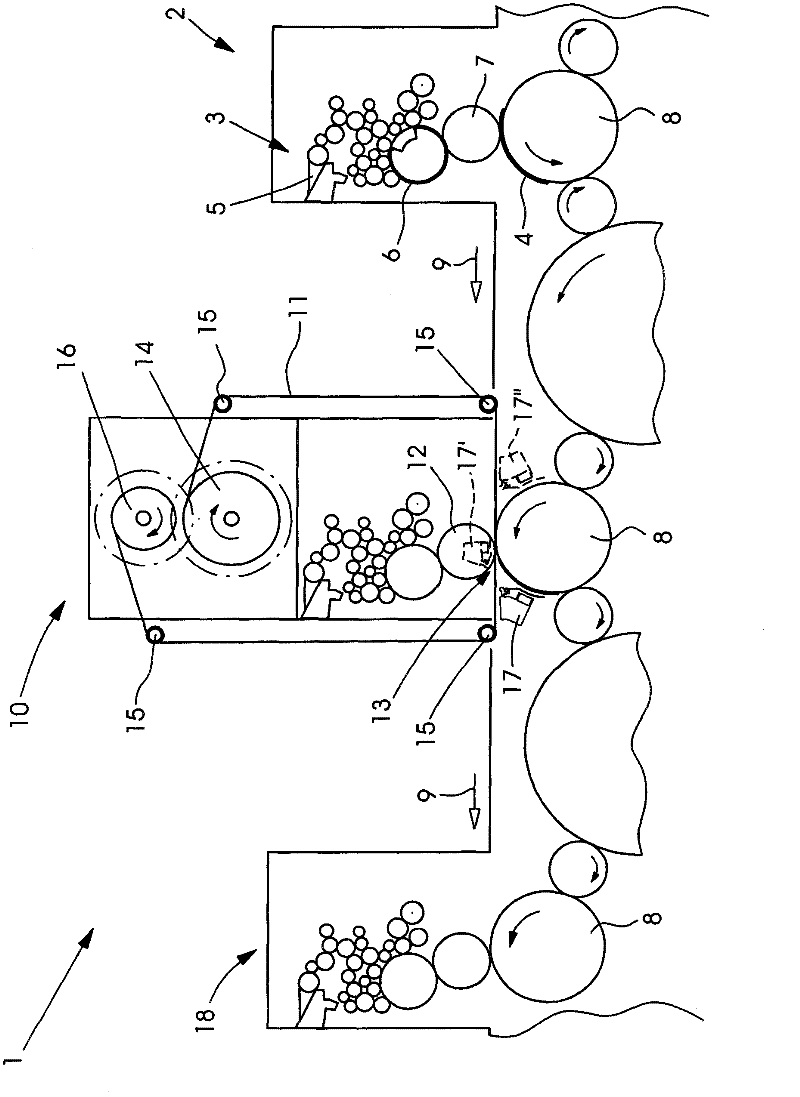

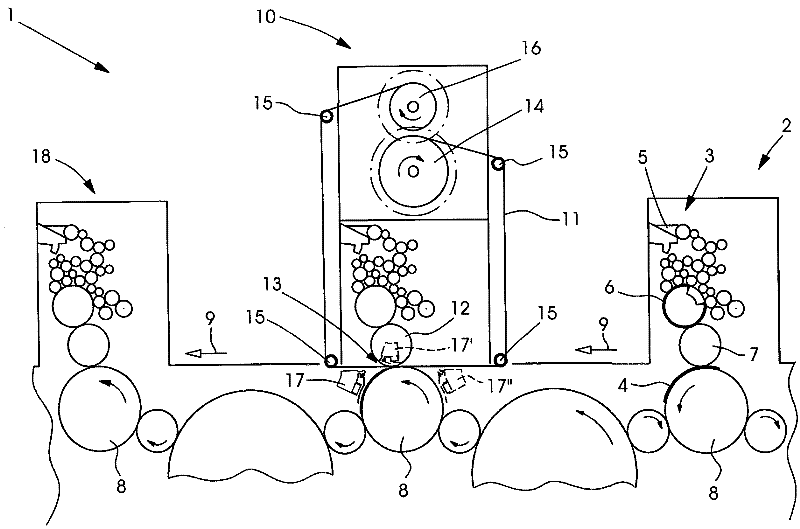

[0021] the only attached figure 1 A partial view of a cold foil embossing device 1 is schematically shown. The cold foil embossing device 1 comprises at least one application device 2 arranged upstream of the transfer device 10 . The cold foil embossing unit 1 can have one or more subsequent processing units, for example printing units 18 , downstream of the transfer unit 10 . A further sheet processing device arranged upstream of the application device 2 is likewise conceivable.

[0022] The adhesive 3 is applied to the sheet 4 in the application device 2 . For this purpose, adhesive 3 is provided in an adhesive supply 5 . For example, the adhesive 3 can be applied from the adhesive supply 5 to the printing plate 6 by means of a conventional ink unit. For this purpose, the printing forme 6 is tensioned on the forme cylinder. The adhesive 3 can also be applied to the printing form in a similar manner by means of a dampening device. An inking unit or dampening unit is esp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com