Gallium nitride-based chip with ceramic substrate and manufacturing method

A gallium nitride-based, ceramic substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the complex process of stripping sapphire substrates, low thermal conductivity of sapphire substrates, and matching of thermal expansion coefficients Poor and other problems, to achieve the effect of small stress, reduced defect density, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation examples of the present invention are used to illustrate the principle of the present invention, rather than limit the present invention to the following specific implementation examples.

[0058] Note that the following apply to all embodiments of the invention:

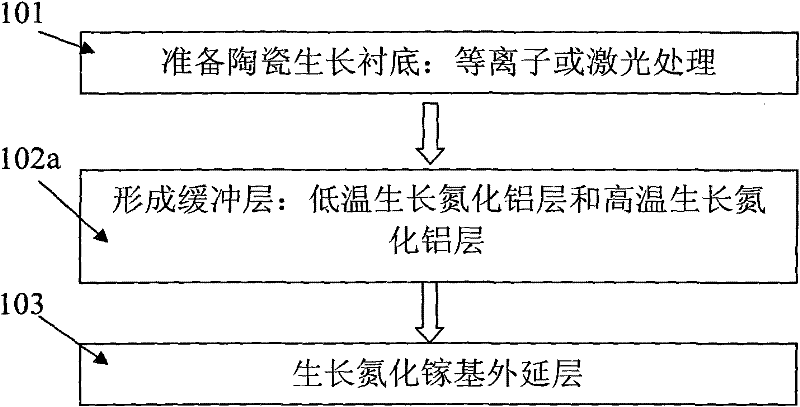

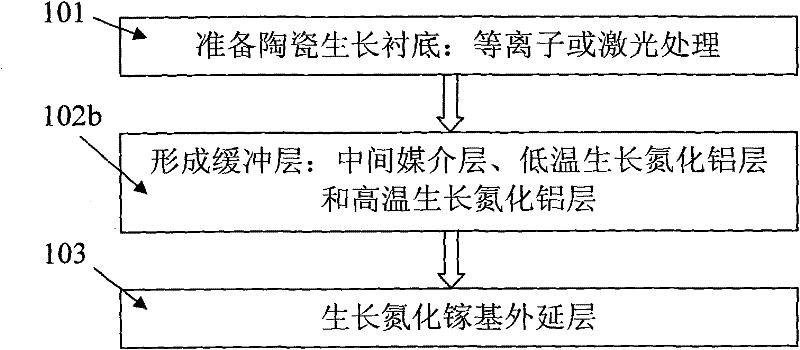

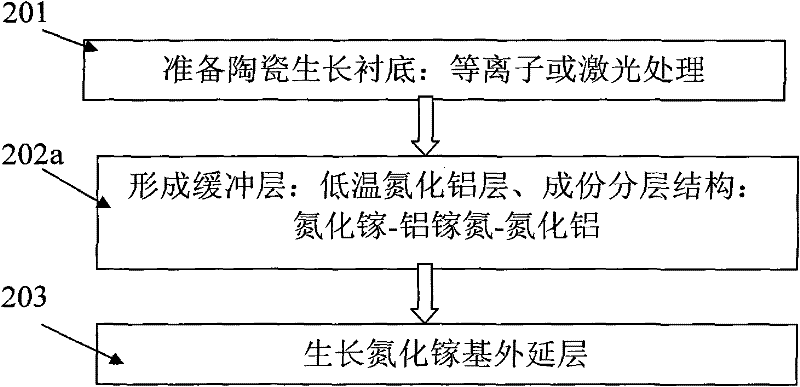

[0059] (1) The gallium nitride-based chip of the front-mount structure of the ceramic substrate of the present invention comprises a ceramic substrate, a buffer layer, and a gallium nitride-based epitaxial layer. A buffer layer is formed on the ceramic substrate, and a GaN-based epitaxial layer is formed on the buffer layer.

[0060] (2) Ceramic substrates include aluminum nitride ceramic substrates, alumina ceramic substrates, silicon carbide ceramic substrates, boron nitride ceramic substrates, zirconia ceramic substrates, magnesium oxide ceramic substrates, silicon nitride ceramics Substrate, zirconia ceramic substrate, beryllium oxide ceramic substrate.

[0061] (3) Plasma tr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap