Hydrogen sensor

A sensor and pressure sensor technology, applied in the field of hydrogen sensors, can solve problems such as the increase of pressure in the detection chamber, and achieve the effects of short time constant, high sensitivity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

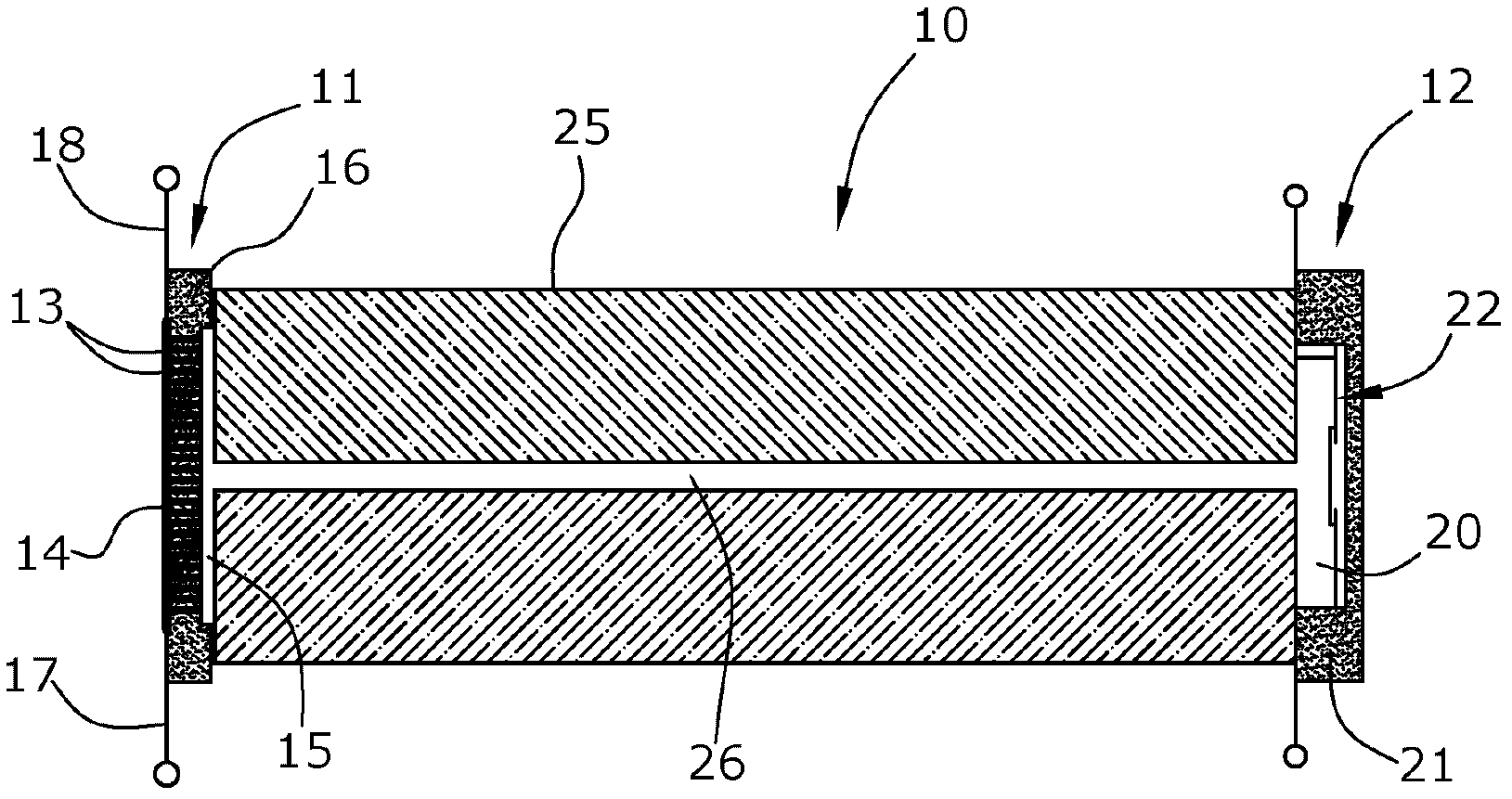

[0028] The hydrogen gas sensor has a pressure-tight housing 10 which is closed at one end by a carrier part 11 made of silicon and at the opposite end by a second carrier part 12 made of silicon. The carrier forms an end wall of the housing. The housing 10 comprises the smallest possible gas volume.

[0029] The first carrier 11 is a plate made of silicon material, the thickness of which is so great that the plate can withstand atmospheric pressure. The first carrier 11 is provided with a large number of through-throughs 13 . These are holes that pass through. A membrane 14 made of palladium is located on the outer side of the first carrier 11 . The membrane is a thin film with a thickness of approximately 1 μm.

[0030] On the inner side of the housing there is provided a carrier 11 with a recess 15 which is surrounded by a raised edge 16 . The membrane 14 can be heated by direct current, or the membrane can be provided with an additional heating layer. Another possibil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com