Energy saving device and energy saving method of solvent purifying system of fluidized floatation bed

A purification system and energy-saving device technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low-concentration solvent waste gas energy saving and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

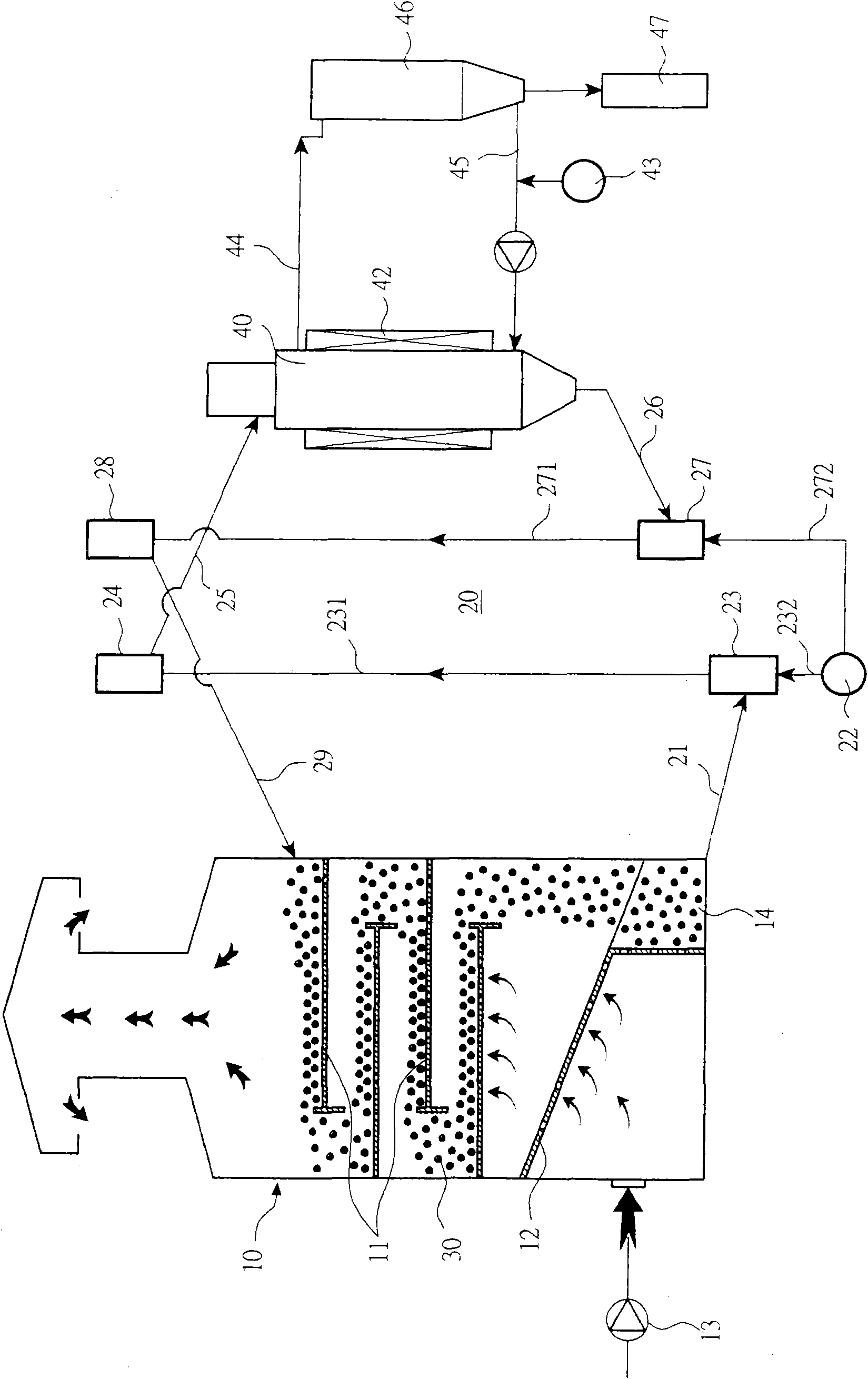

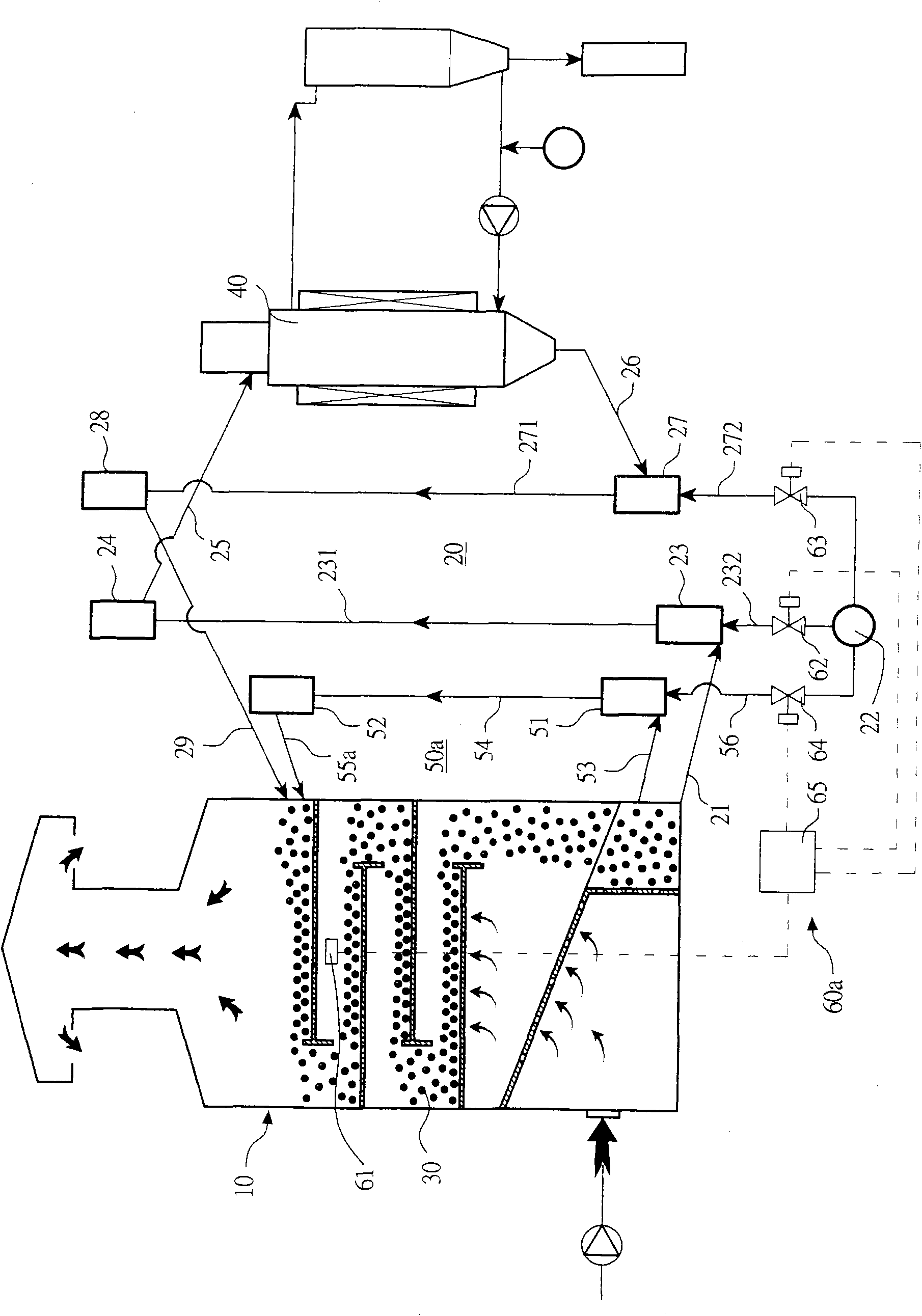

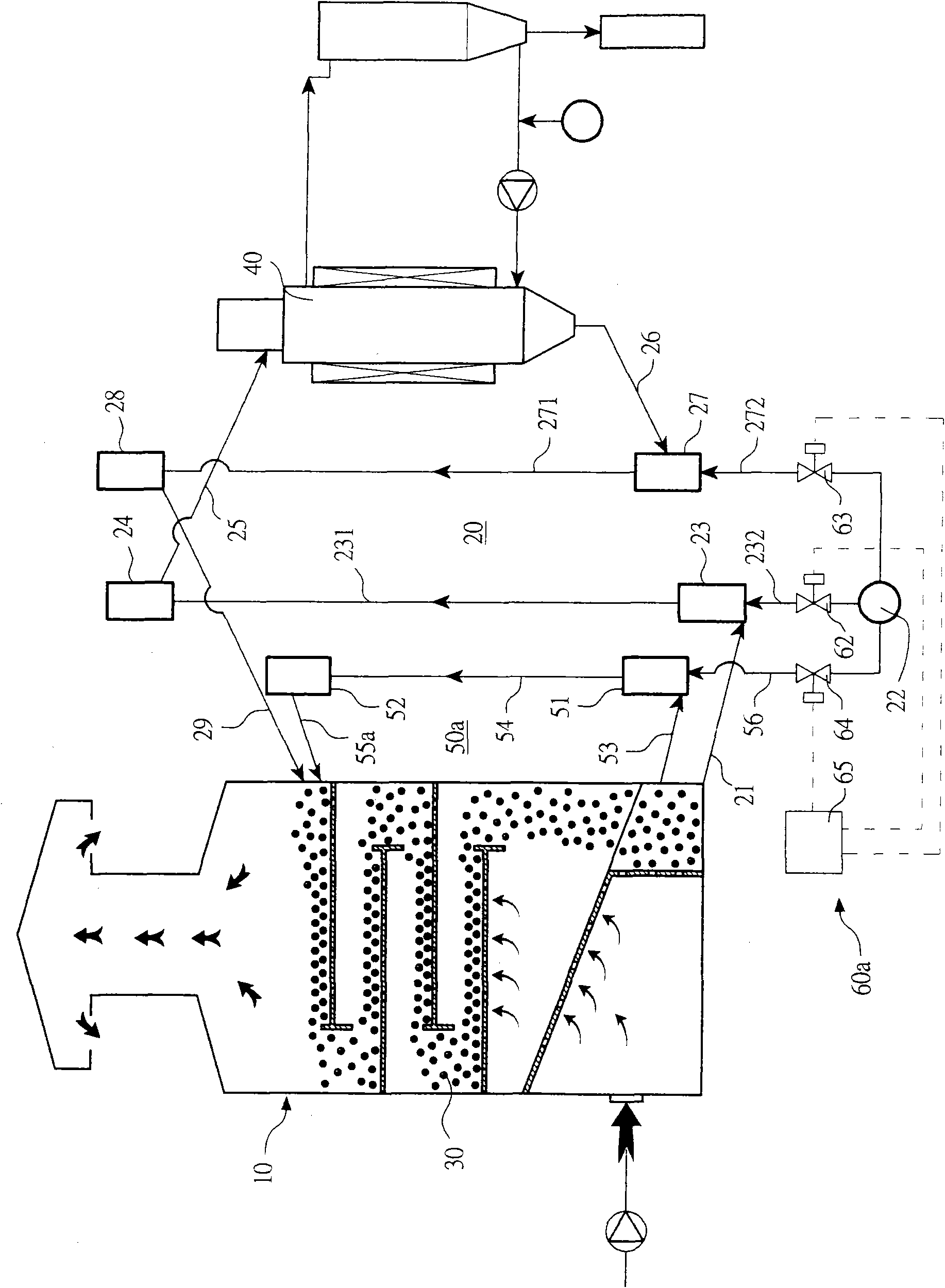

[0054]First, see figure 1 As shown, a common fluidized floating bed solvent purification system includes: a fluidized floating bed 10, allowing the adsorbent 30 to fall from the top to the bottom to absorb the solvent in the waste gas; a desorption tower 40, allowing the adsorbent 30 to The top falls to the bottom and the adsorbed solvent is heated and desorbed; an adsorbent material absorption and desorption conveying device 20 transports the adsorbent material 30 falling to the bottom of the fluidized floating bed 10 to the top of the desorption tower 40, and The adsorbent material 30 at the bottom of the desorption tower 40 is transported to the top of the fluidized floating bed 10 .

[0055] Furthermore, the adsorption and desorption conveying device 20 of the adsorbent includes: a first conveying gas source 22, a first lower conveying transfer device 23, a first upper conveying adapter 24, a second lower conveying transfer device 27, a second upper conveying device Deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com