Improved full-automatic forming machine for crayon

An improved and fully automatic technology, applied in non-active pencils, printing, writing utensils, etc., can solve the problems of low efficiency in mass production, non-continuous production, and less output, and achieve strong practicability, improve production efficiency, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

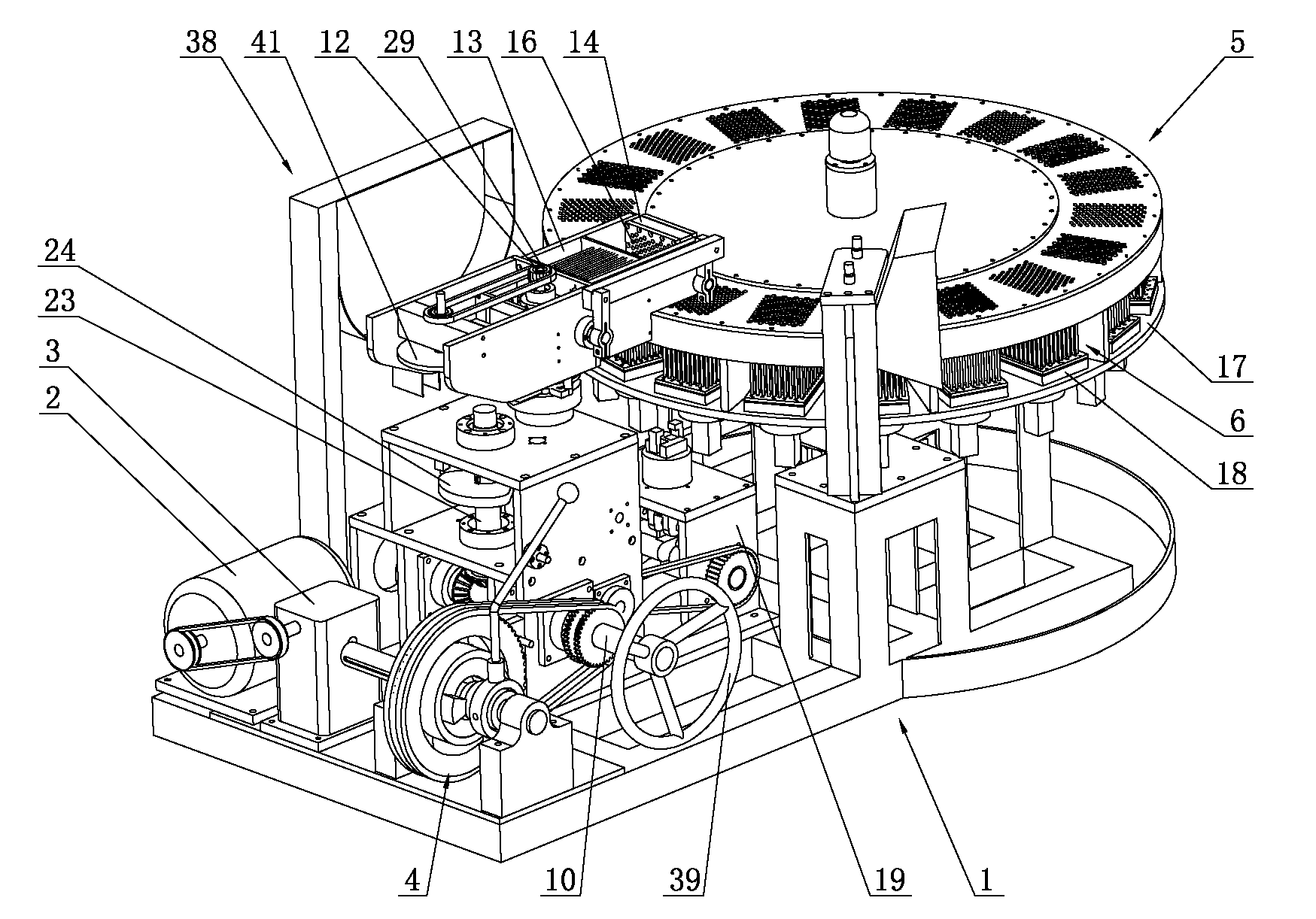

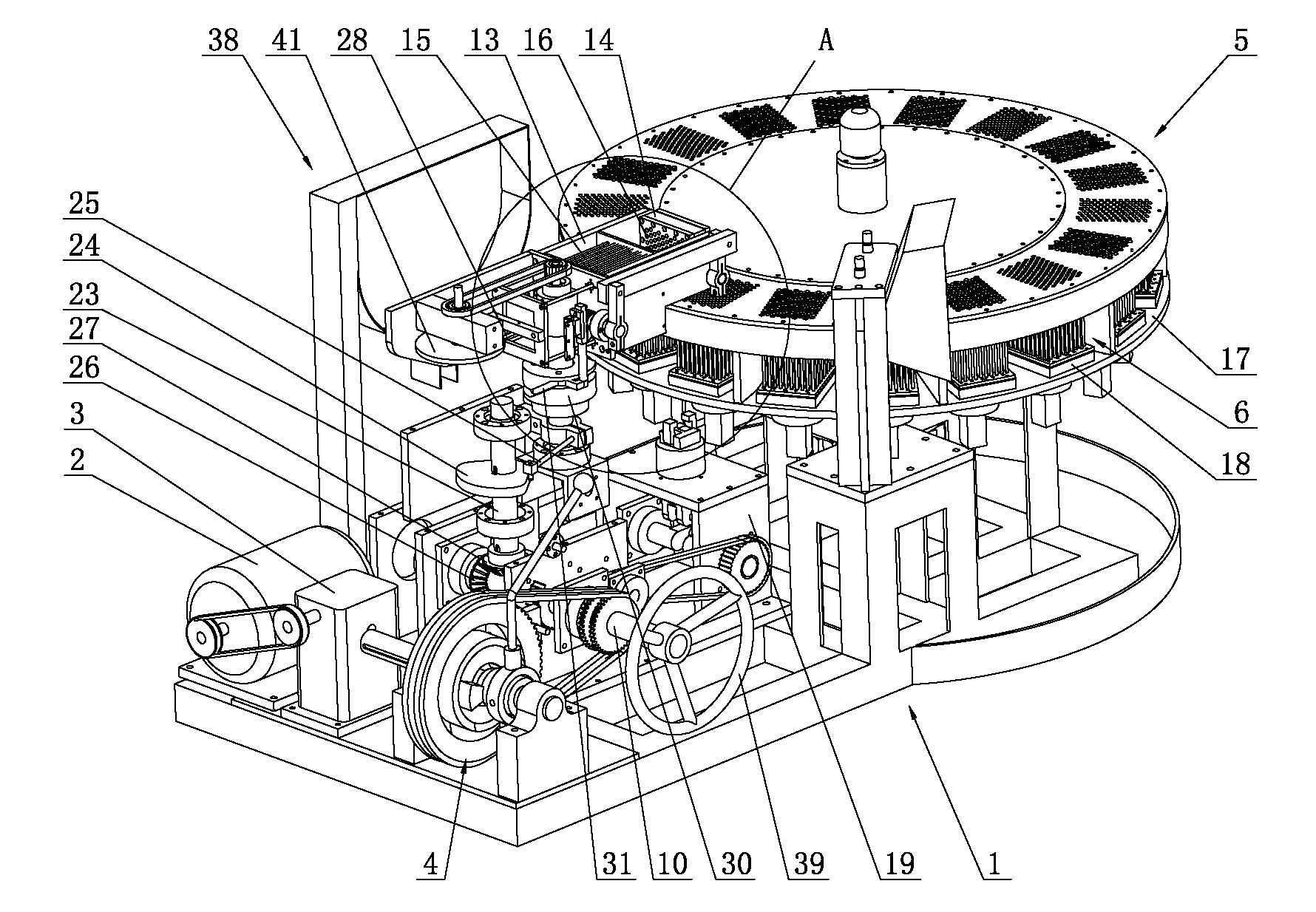

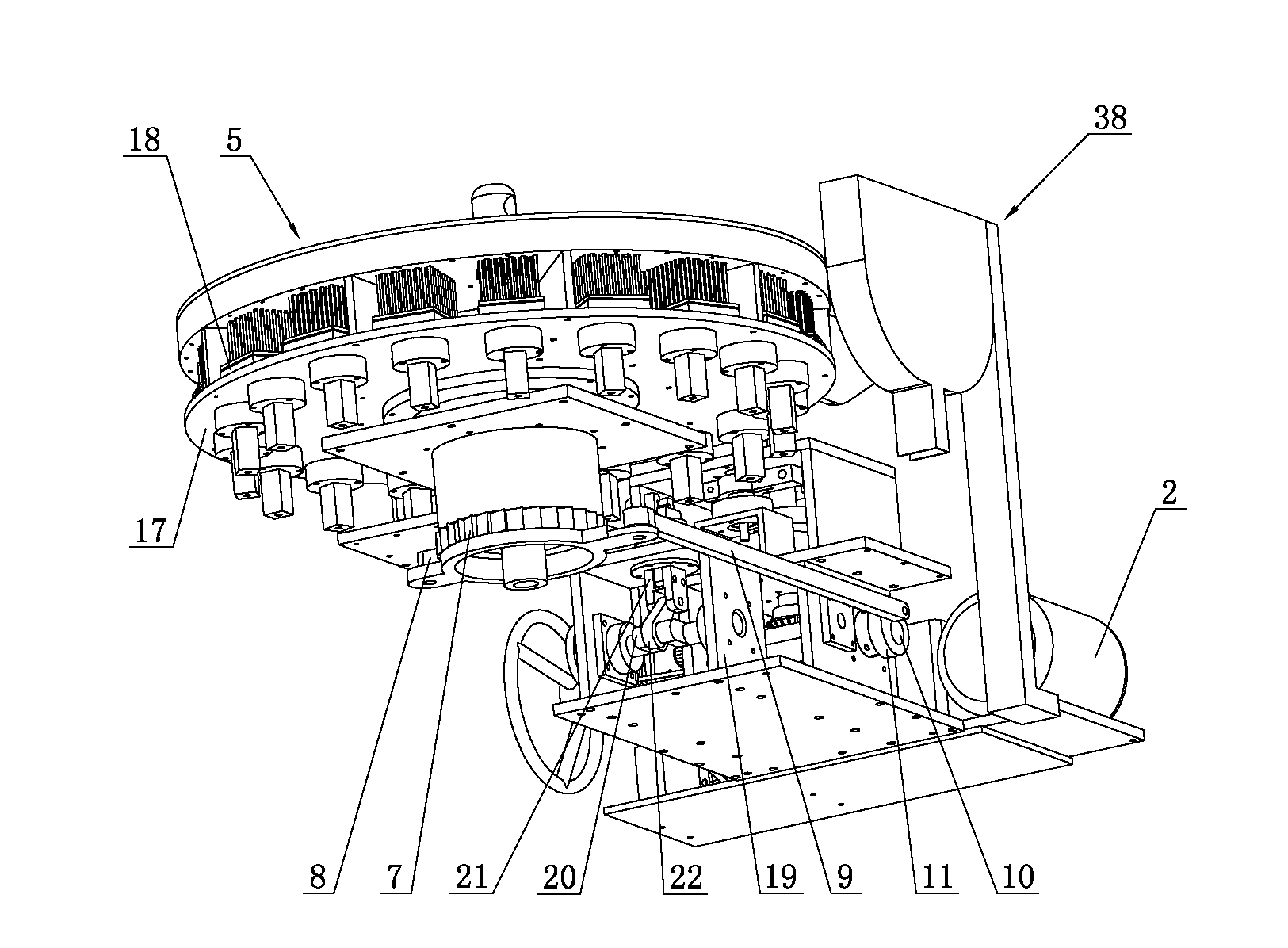

[0021] Such as Figure 1 to Figure 5 As shown, an improved crayon automatic molding machine includes a frame 1, a motor 2 arranged on the frame 1, a reduction box 3 connected to the motor 2, a clutch 4 connected to the reduction box 3, and a frame 1 The mold basin 5, the mold tube arranged on the mold basin 5 and the ratchet mechanism for driving the mold basin 5 to rotate intermittently, the first insert rod 6 is arranged on the side of the mold basin 5, the ratchet mechanism includes a ratchet 7, and is connected with the ratchet 7 The pawl 8 and the first connecting rod 9 hinged with the pawl 8; the frame 1 is provided with a first transmission shaft 10, and the first transmission shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com