Overturning-preventing torque limiter and movable crane

A technology of mobile cranes and moment limiters, which is applied in the directions of cranes, load hanging components, transportation and packaging, etc., and can solve problems such as increased amplitude and load, failure to reflect, increased crane tipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

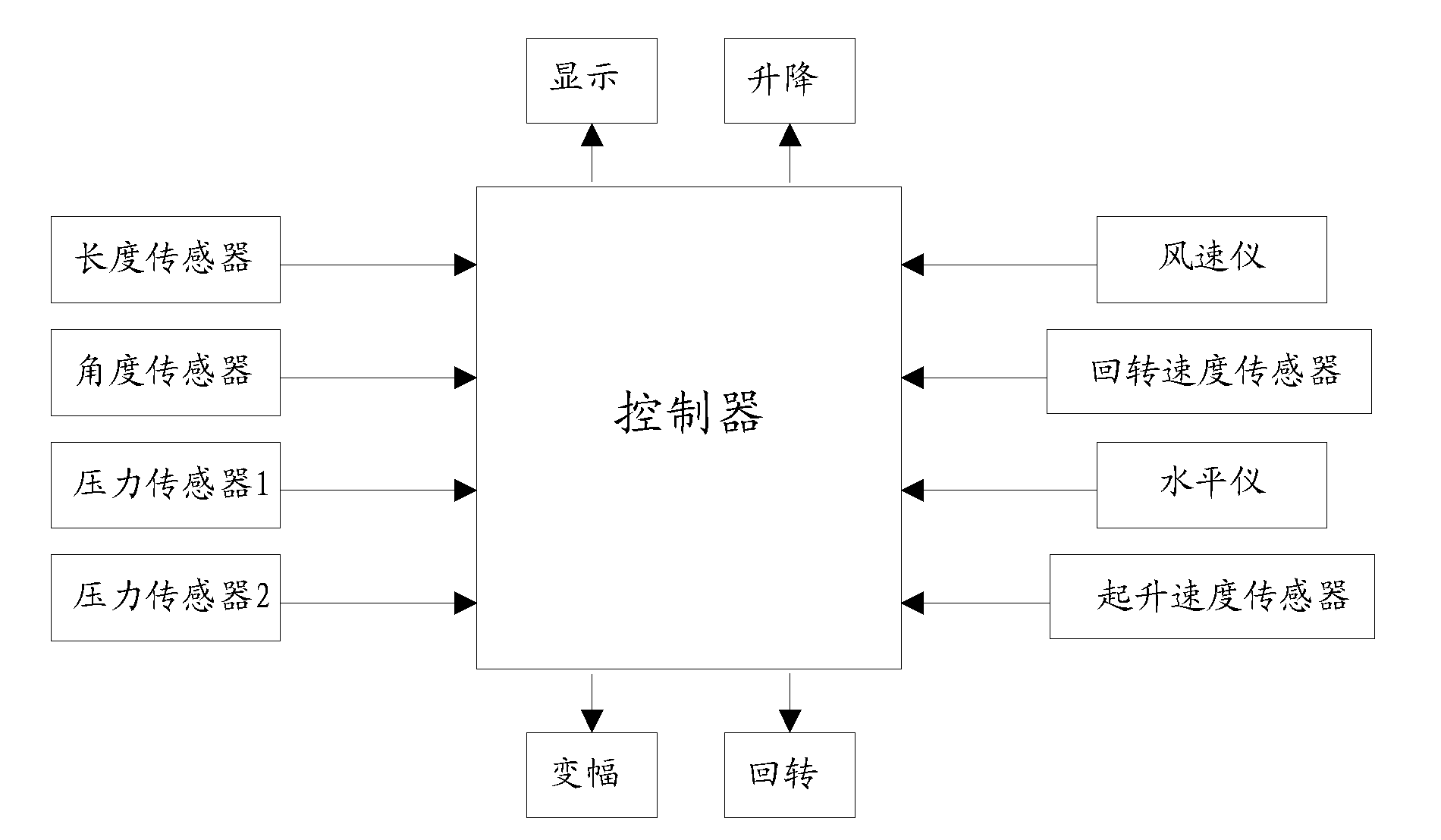

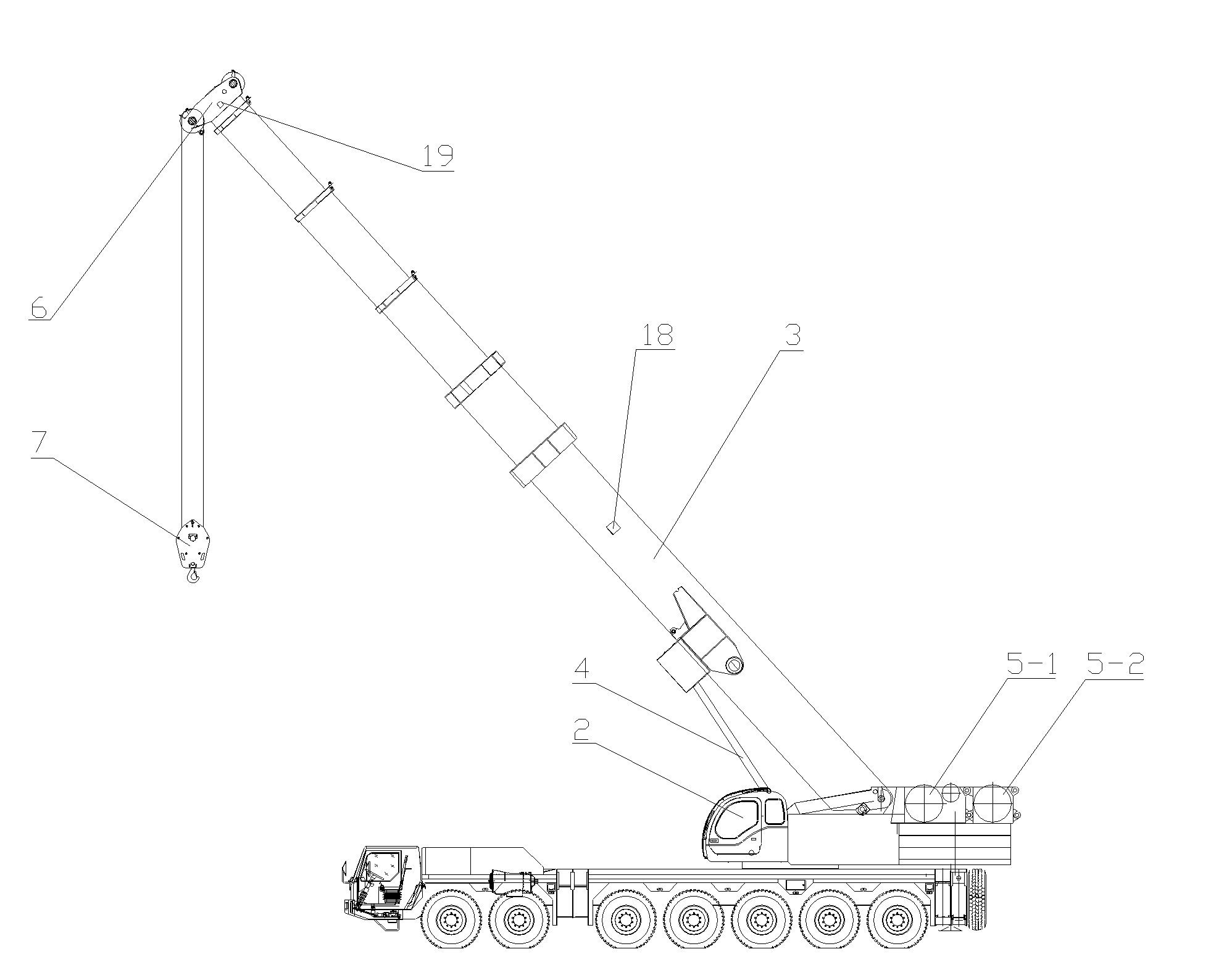

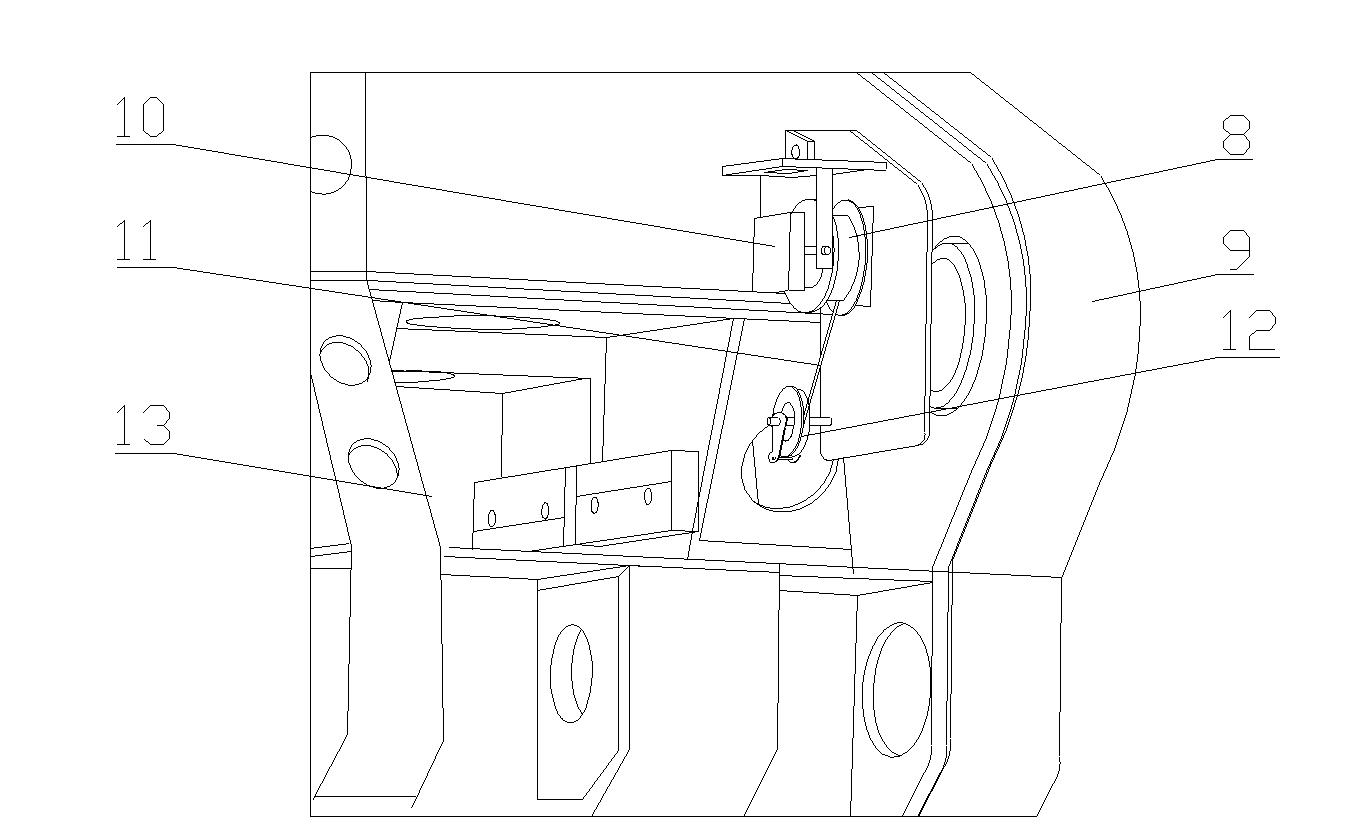

[0037] The core of the present invention is to provide an anti-rollover moment limiter system. The anti-tipping moment limiter system can accurately reflect the working state of the crane, calculate the moment generated by lifting heavy objects, wind force, inertial force and centrifugal force during the working process, and then can adjust the amplitude angular velocity, acceleration, slewing speed, The lifting speed and acceleration of heavy objects are controlled to prevent tipping accidents caused by dynamic instability of the crane.

[0038] Another core of the present invention is to provide a mobile crane provided with the above-mentioned anti-rollover moment limiter system.

[0039] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] The terms "first, second" and the like in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com