Railcar shock absorber rubber composition

A rubber composition and buffer rubber technology are applied in the field of rubber compositions for buffer rubbers for railway vehicles, and can solve the problems of reduced elastic modulus and difficulty in achieving electrical insulation at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] (Preparation of rubber composition)

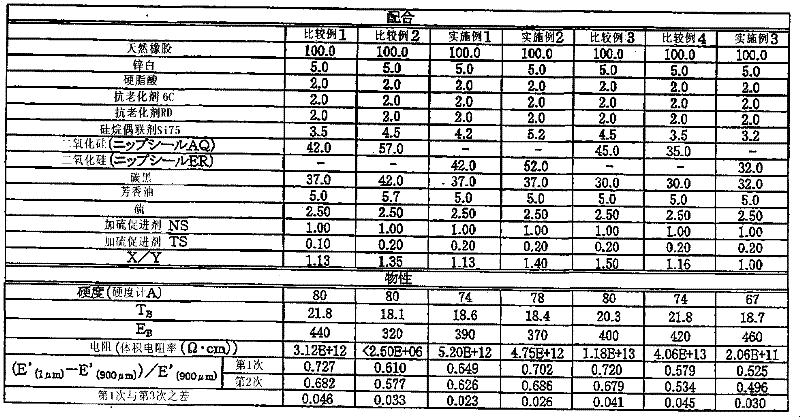

[0031] The rubber compositions of Examples 1 to 3 and Comparative Examples 1 to 4 were blended with 100 parts by weight of the rubber component according to the compounding recipe in Table 1, and kneaded using a normal Banbury mixer to prepare rubber compositions. Each compounding agent described in Table 1 is shown below.

[0032] a) Rubber composition Natural rubber RSS#3

[0033] b) Sulfur ("5% oil treatment sulfur", manufactured by Hosoi Chemical Industry Co., Ltd.)

[0034] c) Vulcanization accelerator

[0035] (A) NS (n-tert-butyl-2-benzothiazolyl sulfenamide) (Nokusera-NS-P), manufactured by Ouchi Shinko Chemical Co., Ltd.)

[0036] (B) TS (tetramethylthiuram monosulfide) (Nokusera-TS), manufactured by Ouchi Shinko Chemical Co., Ltd.)

[0037] d) Carbon black DBP oil absorption is 101cm 3 / 100g of carbon black HAF ("シィスト3", manufactured by Tokai Carbon Co., Ltd.)

[0038] e) Silica

[0039] (A) BET specific surface are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com