Control system of one-frequency one-pump constant pressure water supply equipment

A constant-pressure water supply and control system technology, applied in the water supply pipeline system, water supply equipment, water supply main pipeline, etc., can solve the problems of motor damage, failure site can only stop water, equipment water supply pressure can not be smoothly transitioned, etc., to achieve a simple system Reliable, safe water supply, and rich protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

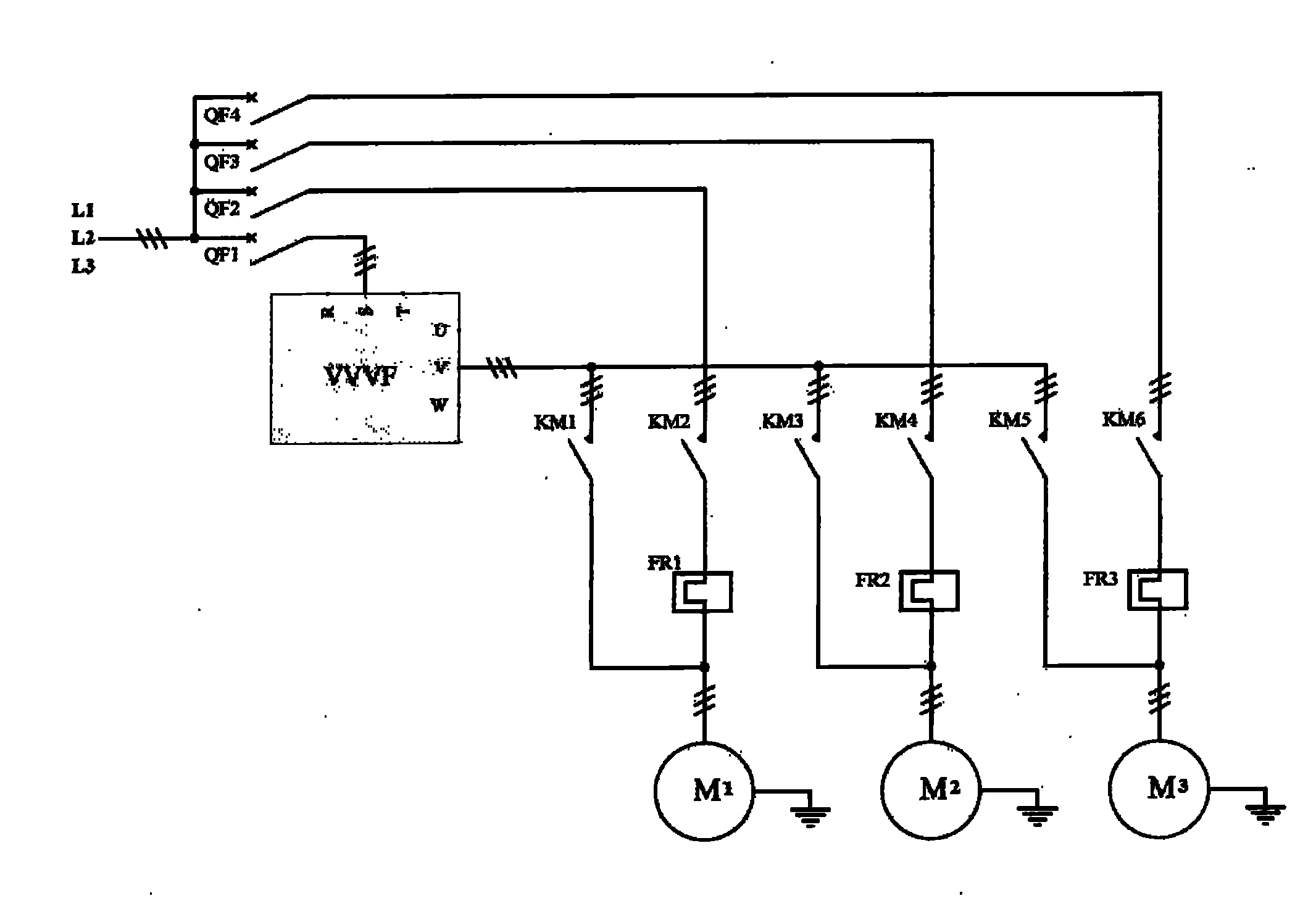

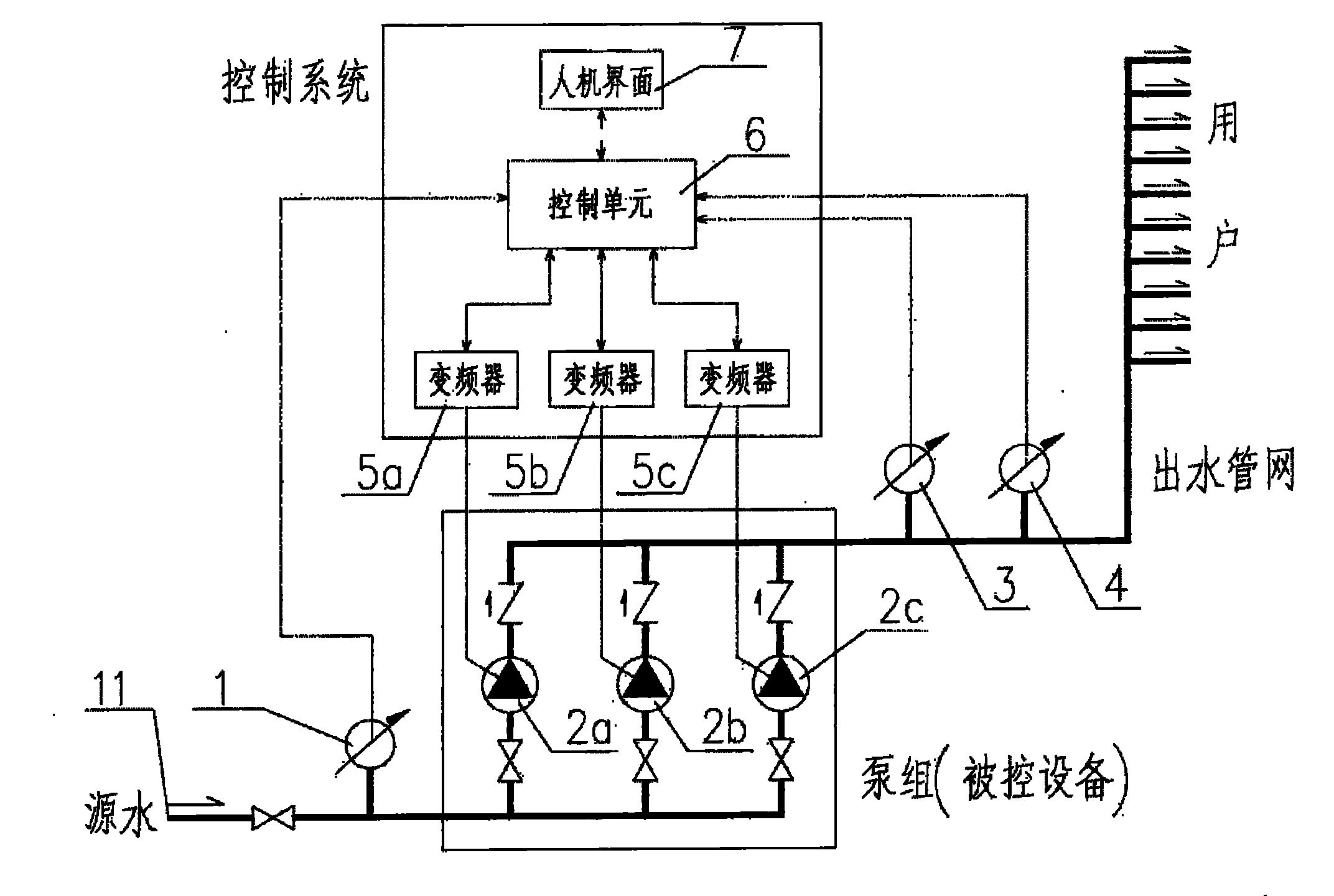

[0030] Such as figure 2 As shown, the present invention is a constant pressure water supply equipment control system adopting one-frequency-one-pump control technology. The cabinet is provided with a frequency converter 5, a control unit 6 and a man-machine interface 7.

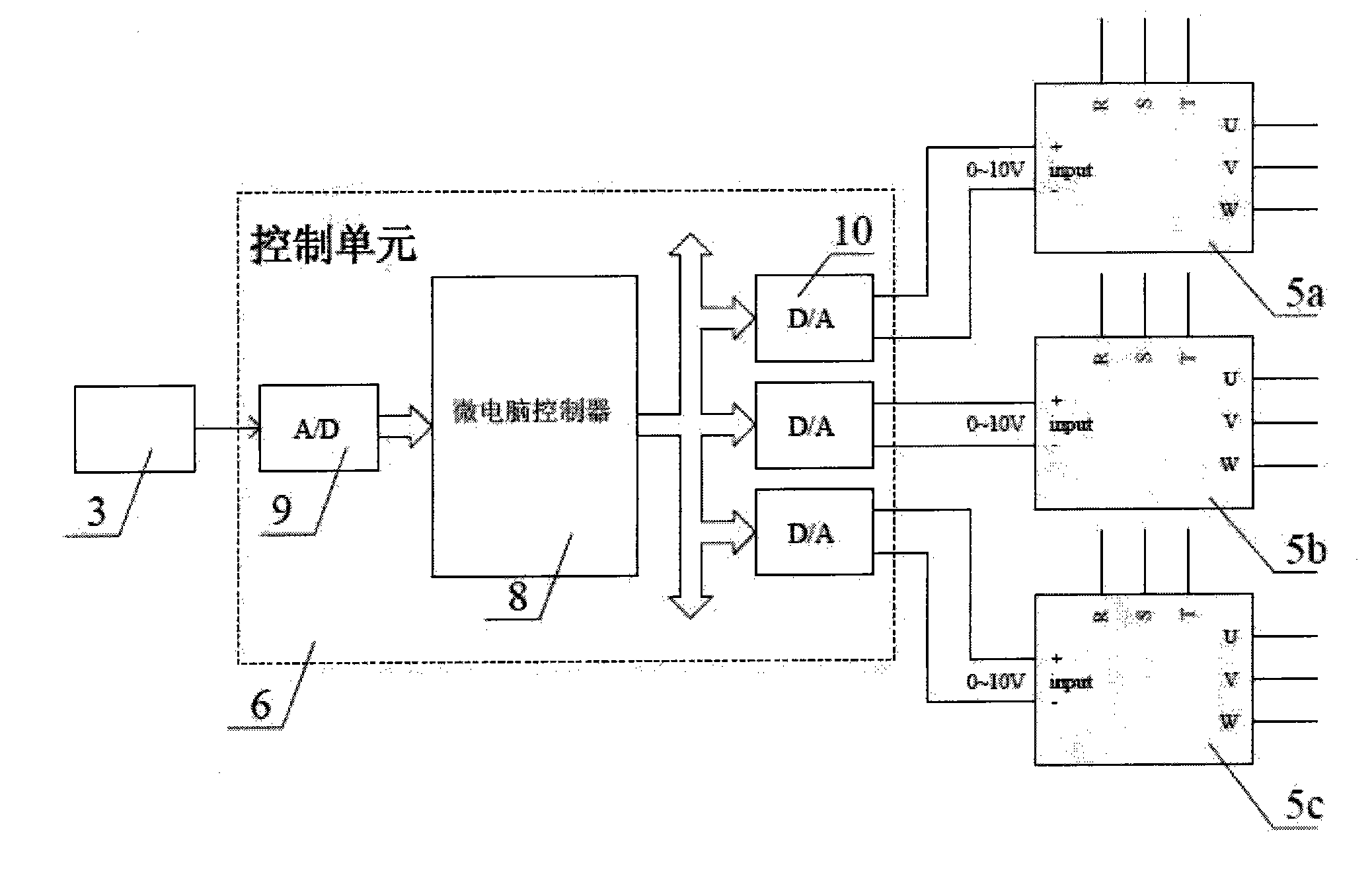

[0031] The control unit 6 includes a microcomputer controller 8, wherein the microcomputer controller can be a PLC or a single-chip microcomputer.

[0032] The control unit 6 includes an A / D conversion module 9 and a D / A conversion module 10. The A / D conversion module 9 is connected to the water outlet pressure sensor instrument 3 to sample the water outlet pressure signal. The microcomputer controller 8 reads the A / D conversion module The pressure data of 9 is used as the pressure feedback signal, and the PID calculation is performed with the set target p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com