Anti-counterfeiting integrated circuit (IC) card, and equipment and method for producing anti-counterfeiting IC card

A production equipment and anti-counterfeiting technology, which is applied to record carriers, instruments, and computer parts used in machines. It can solve problems such as potential safety hazards, and achieve the effects of preventing counterfeit cards, strong corrosion resistance, and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples.

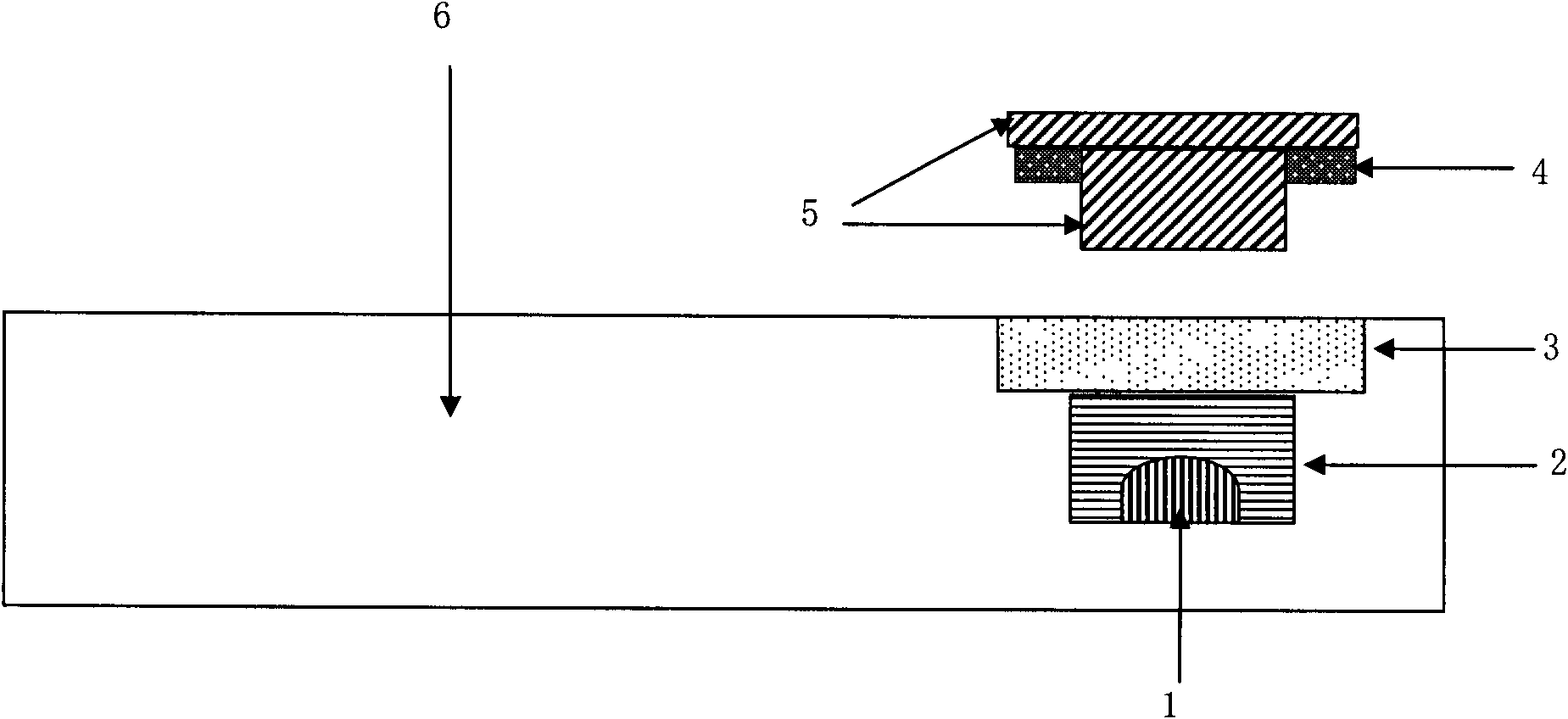

[0052] The invention discloses an anti-counterfeit IC card, see figure 1 , including a sheet-shaped card base 6, a recessed cavity from the surface of the card base 6, and an IC chip 5; the IC chip 5 is embedded in the cavity, and the IC chip 5 is bonded to the wall of the cavity by hot melt adhesive 4 ; Wherein, between the bottom of the cavity and the IC chip 5, a high-strength adhesive 1 is also accommodated.

[0053] Described groove cavity comprises bottom layer groove cavity 2 and first layer groove cavity 3, and the width dimension of described first layer groove cavity 3 is greater than the width dimension of bottom layer groove cavity 2, is consistent with the stepped cross-sectional shape of IC chip 5; Between the cavity 3 and the IC chip 5 is an adhesive layer of hot melt adhesive 4 ; between the bottom cavity cavity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistant | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com