Method and system for coloring plastic molding materials

A molding composition, a technology for plastic molds, applied in the field of systems implementing the method, can solve problems such as production loss, and achieve the effects of low cost, high reproducibility, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

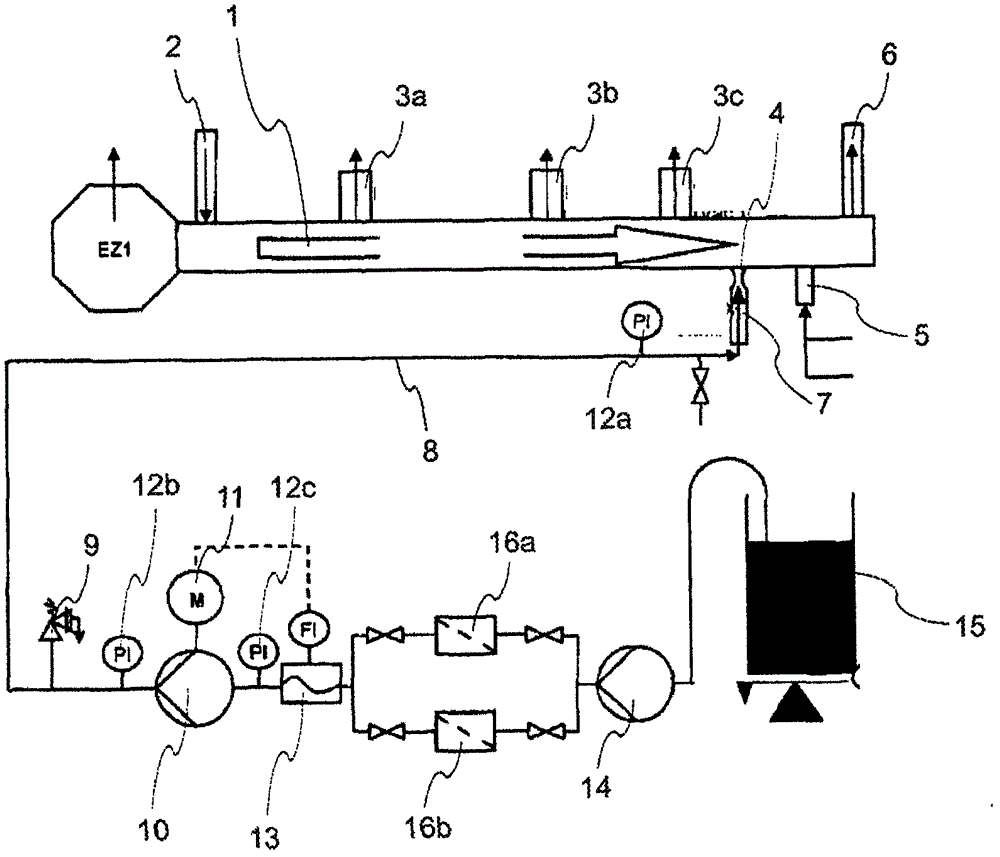

[0142] in accordance with figure 1 In a system of ®, 216 t of polymer mixture comprising 108 t of PMMA polymer and unreacted monomer was introduced into a single screw extruder over a period of 6 days. The first three exhaust sections operate at atmospheric pressure and the fourth at 200 mbar (absolute). The monomer obtained from the exhaust section is condensed and used for the preparation of polymethylmethacrylate.

[0143] The injection valve used was a Phoenix company type 230DN2, PN 400 injection valve with bellows. The pressure inside the extruder at the feed point approximately corresponds to atmospheric pressure, with a temperature of approximately 260°C. The quantity of molding composition flowing through the feed point was 750 kg / hour. 535 g / h of aqueous liquid color was introduced at the feed point using a pressure of 20 bar. The aqueous liquid color used was a composition comprising 20% by weight polyacrylate as a dispersant (commercially available from Ciba ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com