Method for producing cyanoacrylate esters in the presence of transition metal catalysts

A cyanoacrylate, transition metal technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of carboxylic acid nitrile and other directions, can solve the problem of undisclosed heterogeneous catalyst application and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

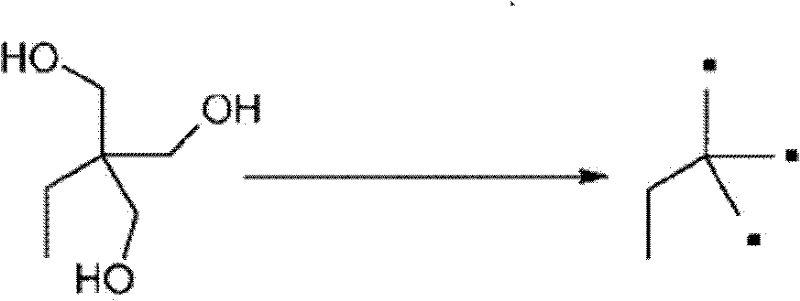

Image

Examples

Embodiment

[0127] substances used

[0128] Tetraisopropyl titanate and methyllithium were purchased from Sigma Aldrich and used without further purification. 1-Decanol was purchased from Merck and used without further purification. Titanium tetrachloride was distilled over copper before use. Silica gel (silica 60, 0.04-0.063 mm, 230-400 mesh, specific surface area 500 m2 / g) was purchased from Macherey-Nagel. Methyl 2-cyanoacrylate [CAS 137-05-3] is commercially available and can be purified by distillation before being used in the process of the present invention.

[0129] 1. Preparation of methyl triisopropyl titanate

[0130] In a 100 ml Schlenk flask at 0°C, TiCl was slowly 4 (1.10ml, 10.0mmol) to Ti(Oi-Pr) in dry diethyl ether (5ml) 4 (8.98ml, 30.0mmol), and the resulting mixture was stirred at 0°C for 10min. After stirring at 22°C for 30 min, dry diethyl ether (15 ml) was added and the mixture was cooled to -40°C. Then dropwise added MeLi(Et 2 1.6M in O, 25.0ml, 40.0mmol) so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com