Apparatus for producing multicrystalline silicon ingots by induction method

A polycrystalline silicon ingot and sensor technology, which is applied in the directions of polycrystalline material growth, chemical instruments and methods, crystal growth, etc., can solve the problems of lowering the quality of polycrystalline silicon ingots and decreasing the productivity of polycrystalline silicon ingots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

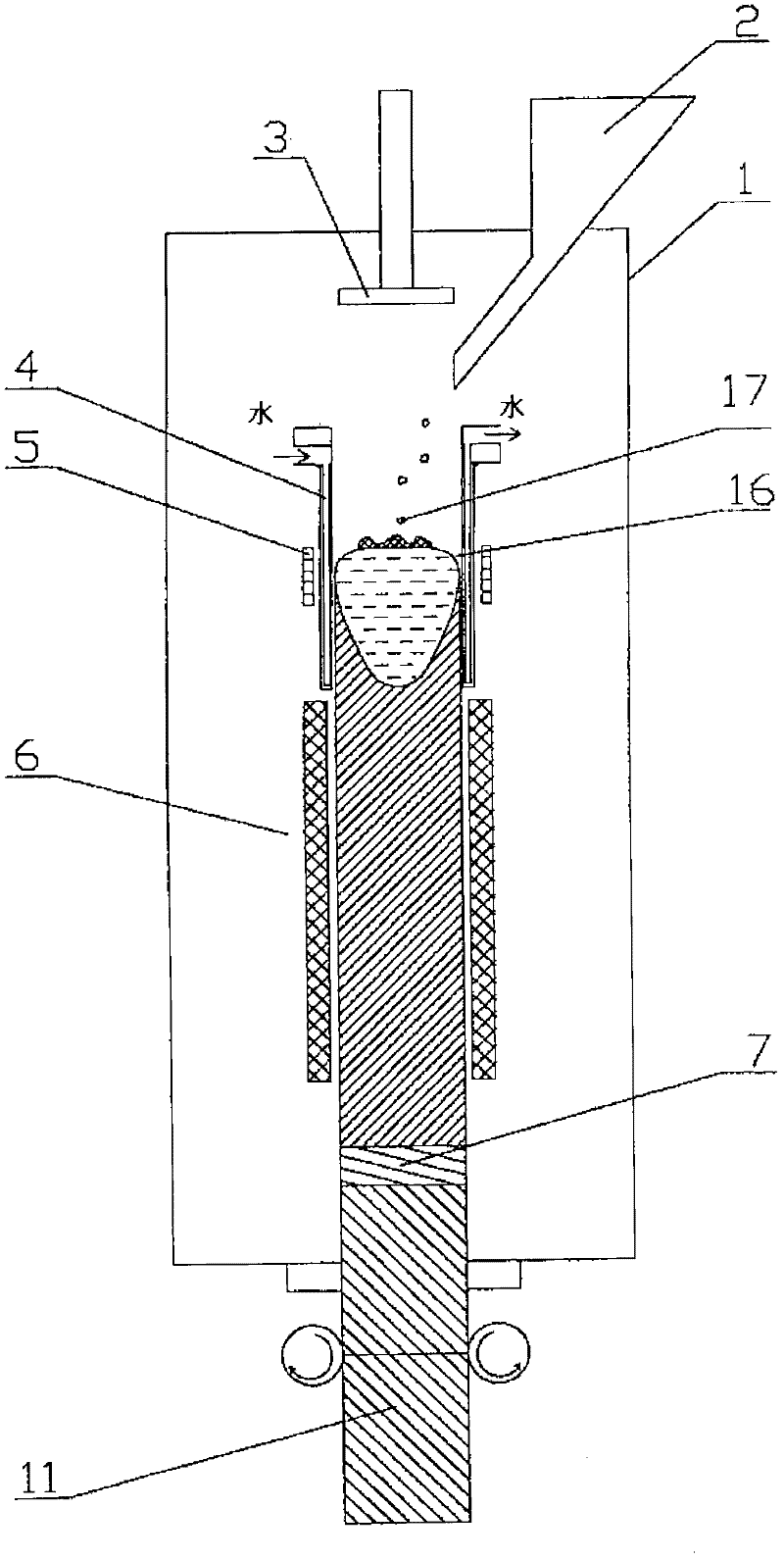

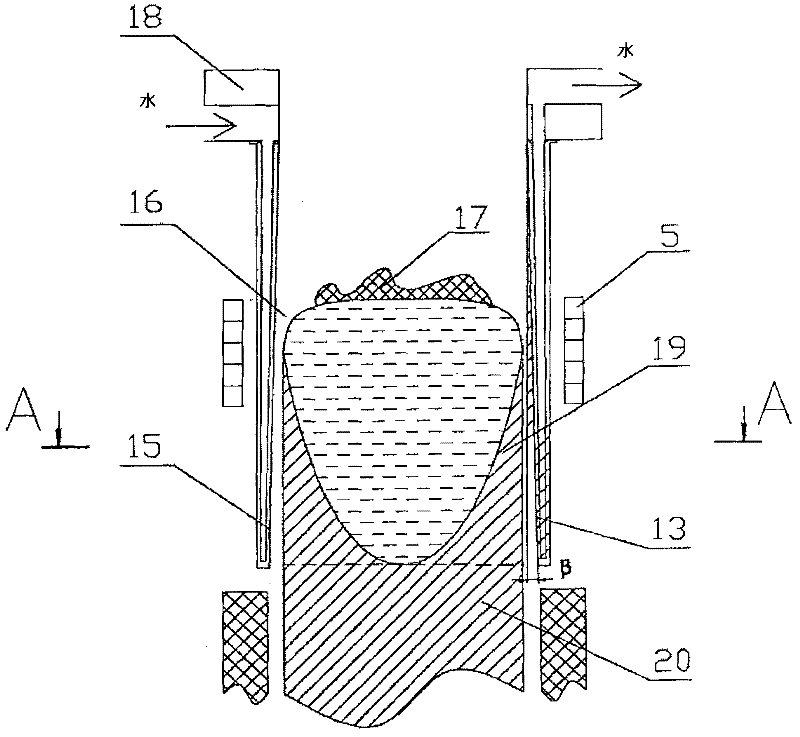

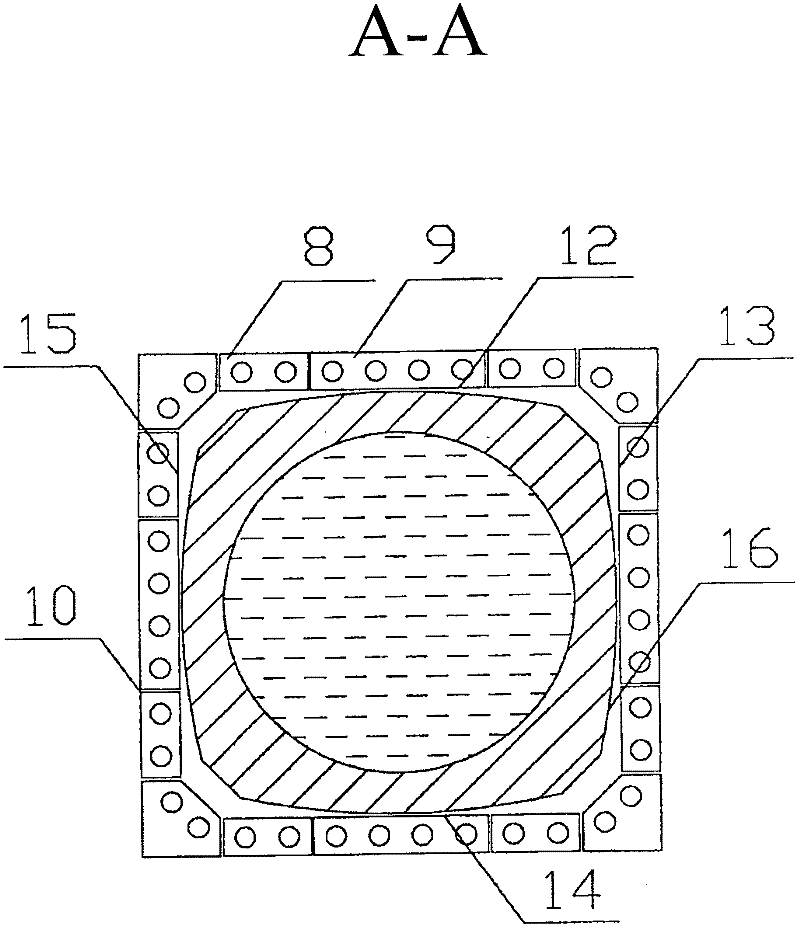

[0031] A device for producing polycrystalline silicon ingots by induction melting ( figure 1 ), including the housing 1 connected to the feed hopper 2. In the housing 1, there are provided a device 3 for starting heating silicon, a cooling crucible 4 surrounded by an inductor 5, and a control cooling compartment 6 arranged below the cooling crucible 4. The cooling crucible 4 is surrounded by a movable bottom 7 and a part 8 and a central part 9 ( image 3 ), the part 8 and the central part 9 are separated by a longitudinal slit 10. The movable bottom 7 is associated with the part 11 for the same longitudinal movement in the control cooling compartment 6. The part 8 and the central part 9 separated by the longitudinal slit 10 form four furnace walls 12, 13, 14 and 15 perpendicular to each other. The inner surface of the cooling crucible 4 defines a melting chamber 16 with a square or rectangular cross-section, into which a bulk silicon raw material 17 is added. The central por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com