Method and control unit for operating an electromagnetic actuator

A technology for electromagnetic actuators and control equipment, applied in electrical control, electromagnets, mechanical equipment, etc., to solve problems such as separation and minimum time interval restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

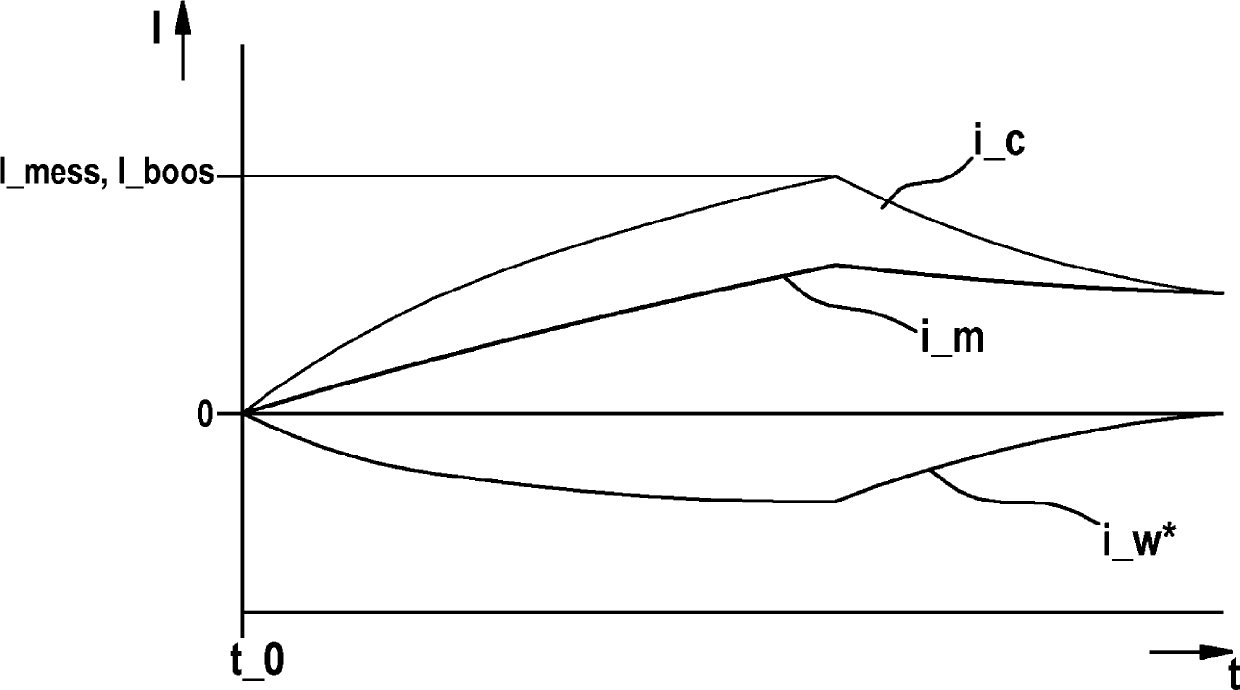

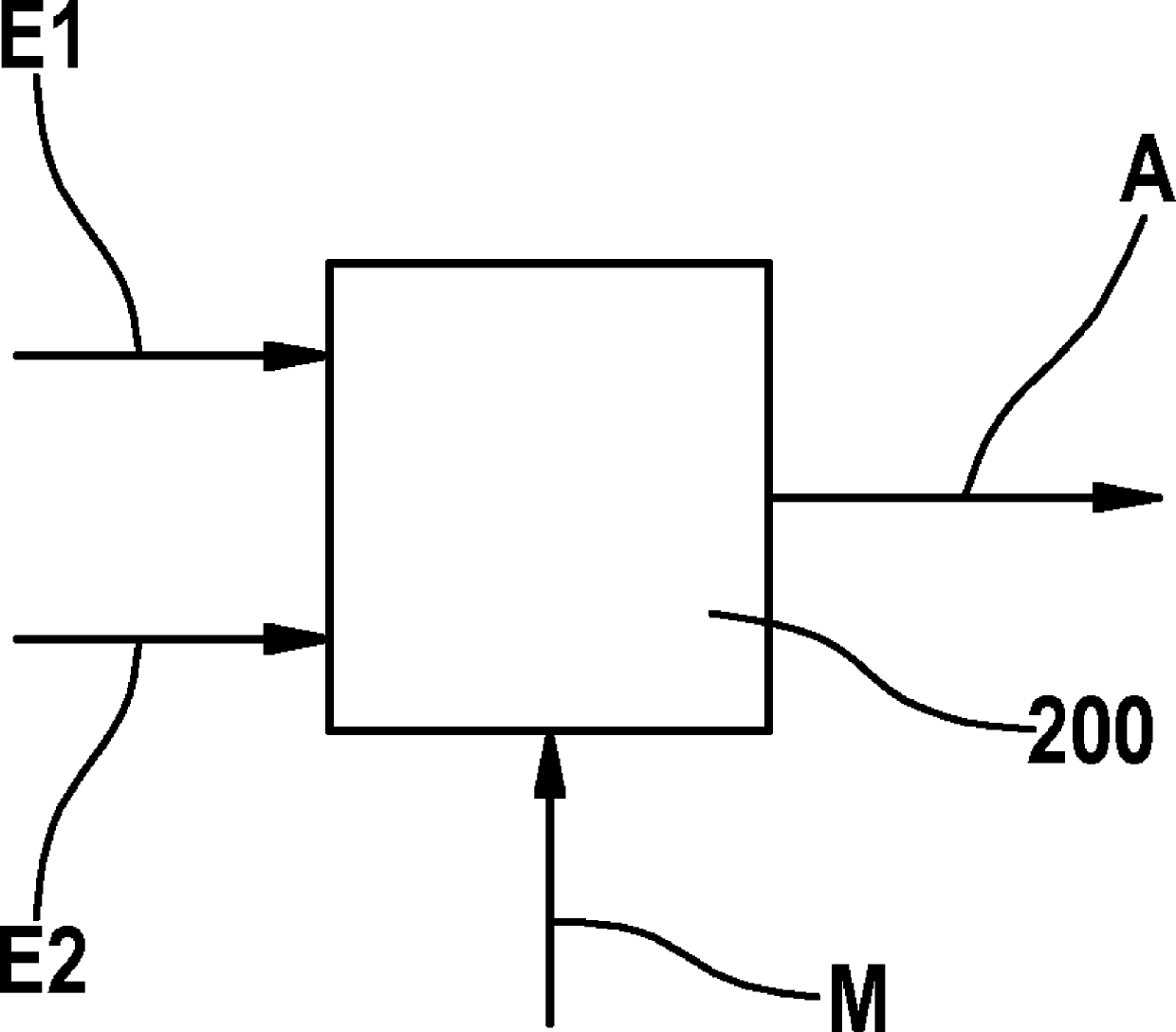

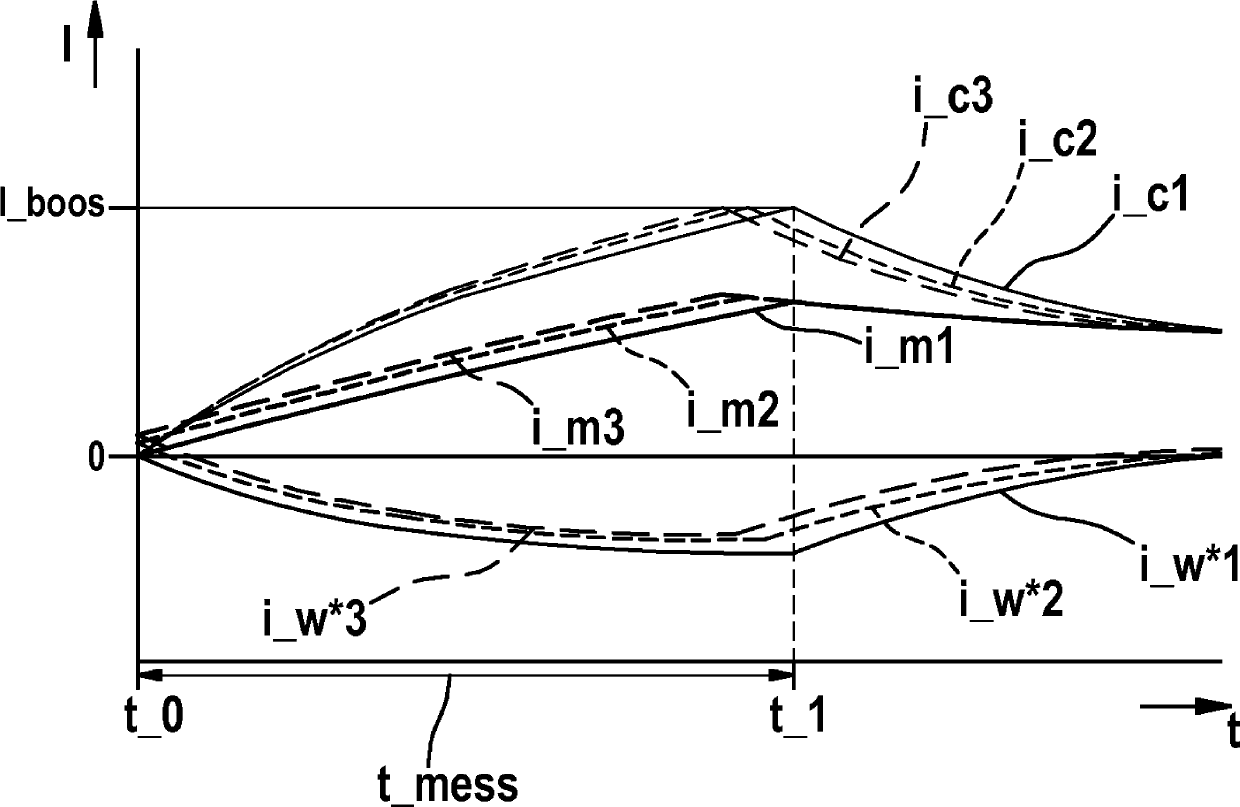

[0023] figure 1 A fuel injection valve 100 of an internal combustion engine of a motor vehicle is shown schematically. Fuel injection valve 100 has a solenoid actuator 10 , which drives at least one component (not shown here) of fuel injection valve 100 , for example a valve needle, in order to bring about fuel injection. Electromagnetic actuator 10 is activated via a control device 20 associated with electromagnetic actuator 10 . The control device 20 has a computing unit known per se, for example a microcontroller or a digital signal processor (DSP) suitable for implementing a computer program representing the method according to the invention.

[0024] figure 2 shows a typical electromagnetic actuator 10 ( figure 1 ) The simplified equivalent circuit diagram of the magnetic circuit 11.

[0025] This equivalent circuit diagram has a resistance R_c representing the ohmic resistance of the primary coil of electromagnetic actuator 10 . Connected in series with this ohmic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com