EGR control system for internal combustion engine

A control system and internal combustion engine technology, applied in engine control, internal combustion piston engine, electrical control, etc., can solve problems such as torque fluctuation, misfire, and increased discharge of unburned fuel components, and achieve the effect of suppressing misfire and suppressing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

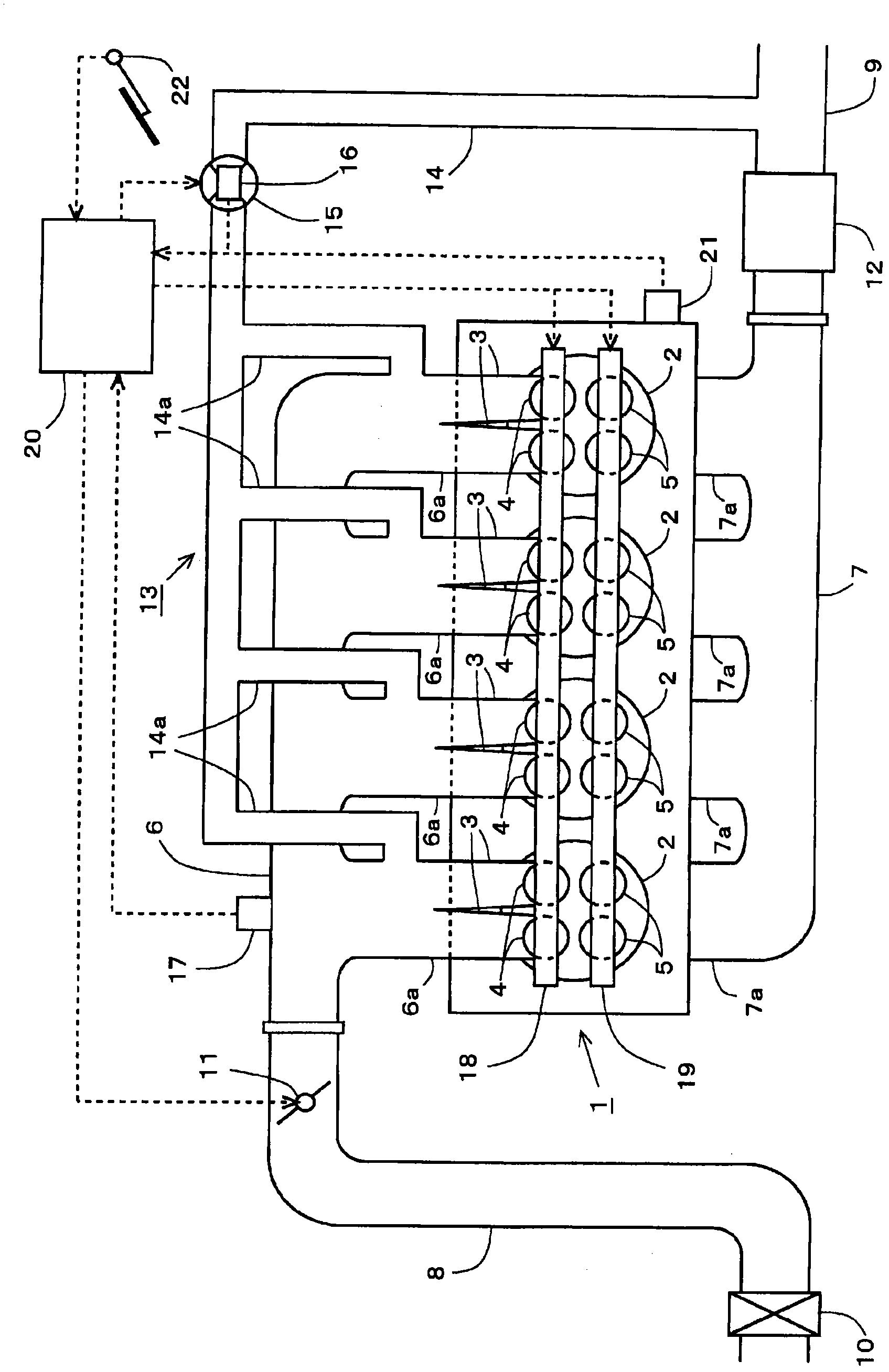

[0064] based on Figure 1 ~ Figure 4 Example 1 of the present invention will be described.

[0065] (Schematic configuration of an internal combustion engine and its intake and exhaust systems)

[0066] figure 1 It is a diagram showing a schematic configuration of an internal combustion engine and its intake and exhaust systems according to the present embodiment. The internal combustion engine 1 is a gasoline engine for driving a vehicle having four cylinders 2 . An intake port 3 and an exhaust port (not shown) are connected to each cylinder 2 . The openings of the intake port 3 and the exhaust port into the cylinder 2 are opened and closed by an intake valve 4 and an exhaust valve 5 , respectively. In addition, in the internal combustion engine 1 , a fuel injection valve and a spark plug (not shown) are provided for each cylinder 2 .

[0067] The internal combustion engine 1 has an intake variable valve train (hereinafter referred to as intake VVT) 18 and an exhaust var...

Embodiment 2

[0108] based on Figure 5 to Figure 7 Example 2 of the present invention will be described. In addition, only the point different from Example 1 is demonstrated here.

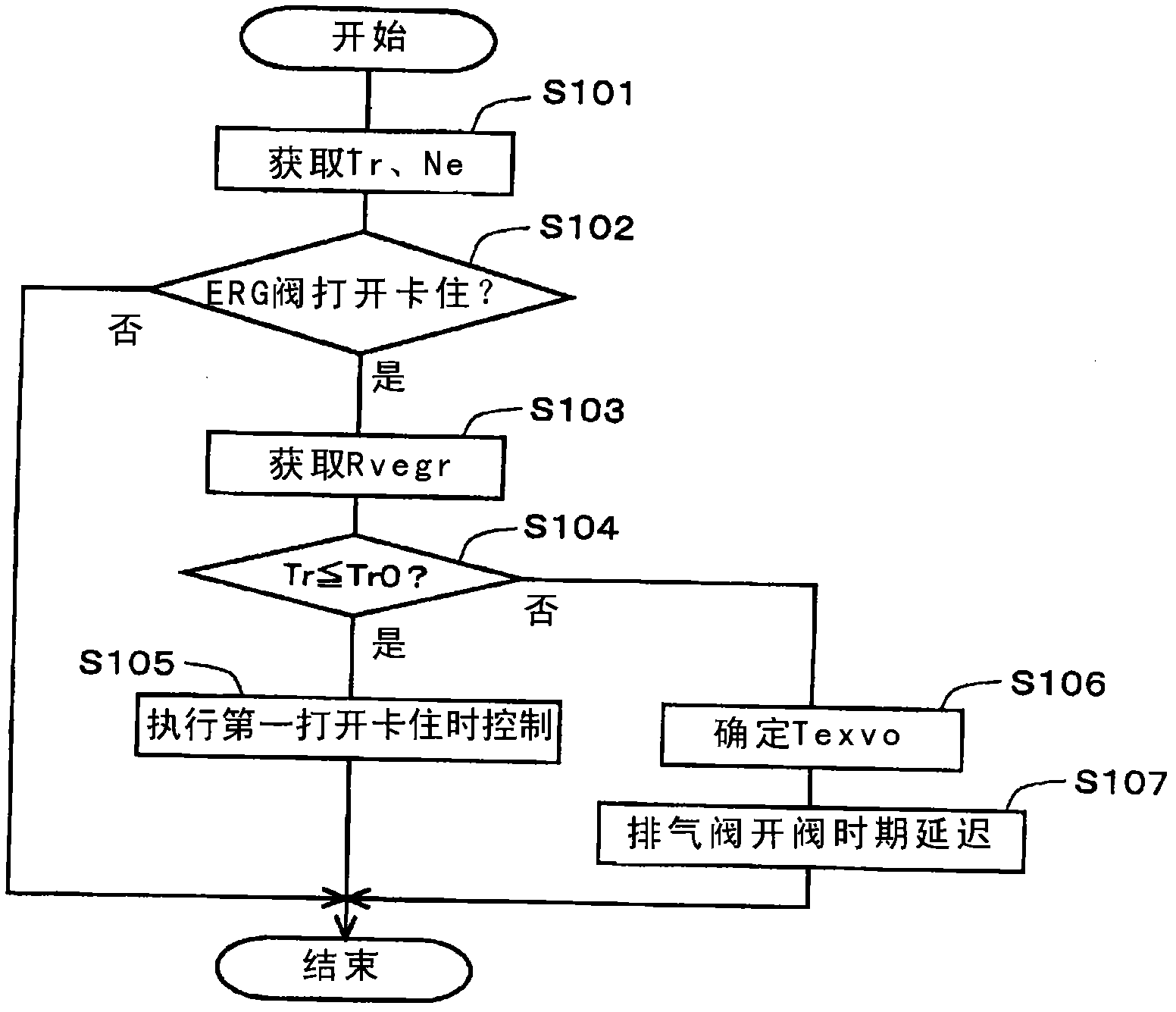

[0109] (Control when EGR valve is open and stuck)

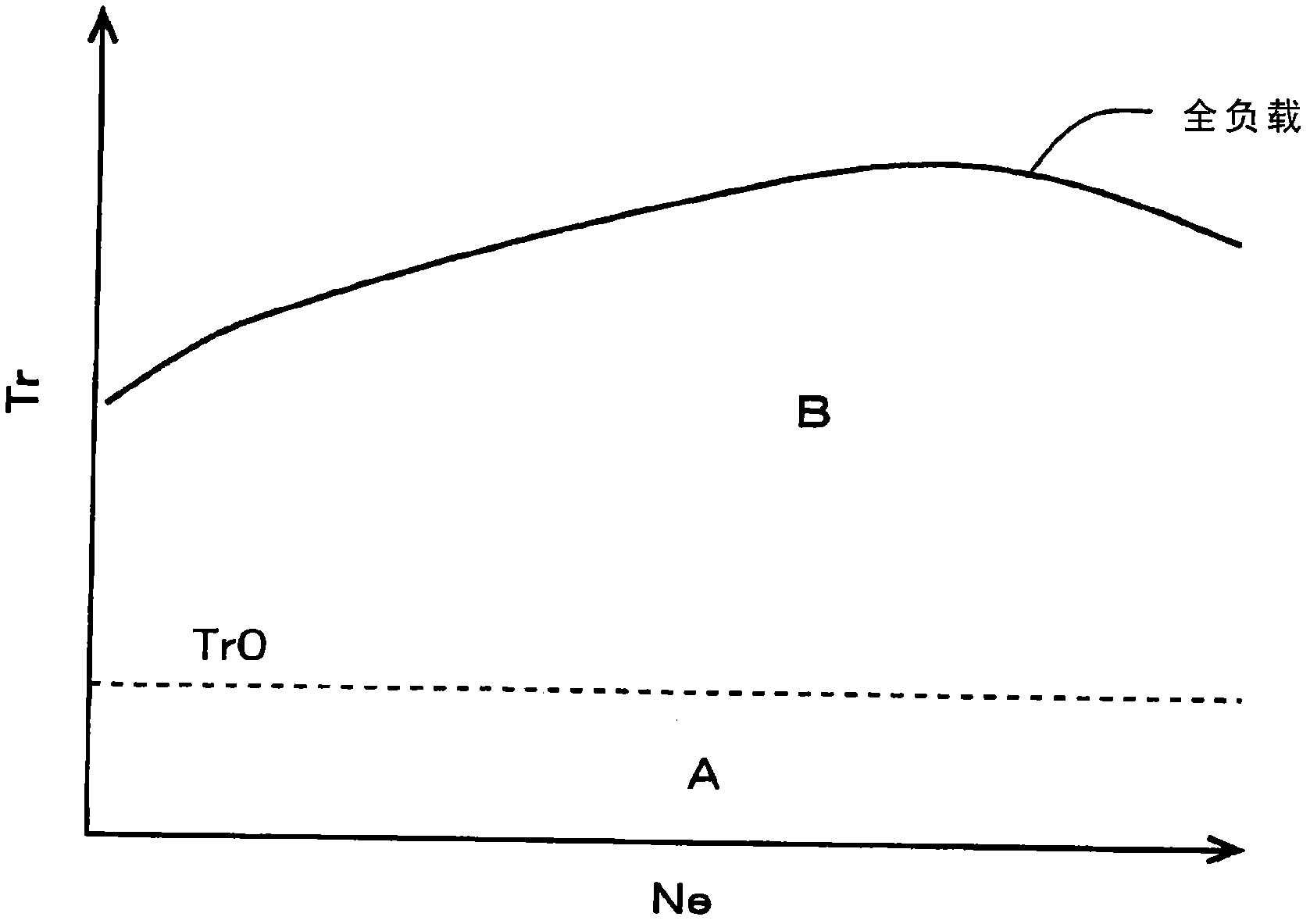

[0110] In this embodiment, when the operating state of the internal combustion engine 1 belongs to figure 2 Even when the EGR valve 15 is open and stuck in the operation region B shown, the increase in the total amount of EGR gas and the EGR between cylinders are suppressed by reducing the exhaust pressure in the exhaust passage 9 in the same manner as in the first embodiment. Deviation of gas volume. However, the method of reducing the exhaust pressure is different from that of Example 1.

[0111] Hereinafter, a method of reducing the exhaust pressure when the EGR valve 15 is open and stuck according to the present embodiment will be described. In the present embodiment, when the opening of the stuck EGR valve 15 is equal to or less than the first predete...

Deformed example 1

[0136] Next, Modification 1 of the present embodiment will be described. In this modified example, when the operating state of the internal combustion engine 1 belongs to figure 2When the EGR valve 15 is open and stuck in the operation region B shown, if the opening degree is less than or equal to the first predetermined opening degree, the air-fuel ratio of the air-fuel mixture of the internal combustion engine 1 is also made higher than the reference air-fuel ratio to reduce the exhaust gas. pressure. In this case, the increase amount of the EGR gas is smaller than when the opening degree of the EGR valve 15 is larger than the first predetermined opening degree. Therefore, the target air-fuel ratio when the air-fuel ratio of the air-fuel mixture of the internal combustion engine 1 is made higher than the reference air-fuel ratio is set to a lower value than when the opening degree of the EGR valve 15 is larger than the first predetermined opening degree. Accordingly, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com