Control system for multiple-fuel internal combustion engine

A control system, a technology for an internal combustion engine, applied in the directions of fuel injection control, engine control, internal combustion piston engine, etc., can solve problems such as restrictions, and achieve the effect of suppressing the occurrence of misfire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] [Summary structure]

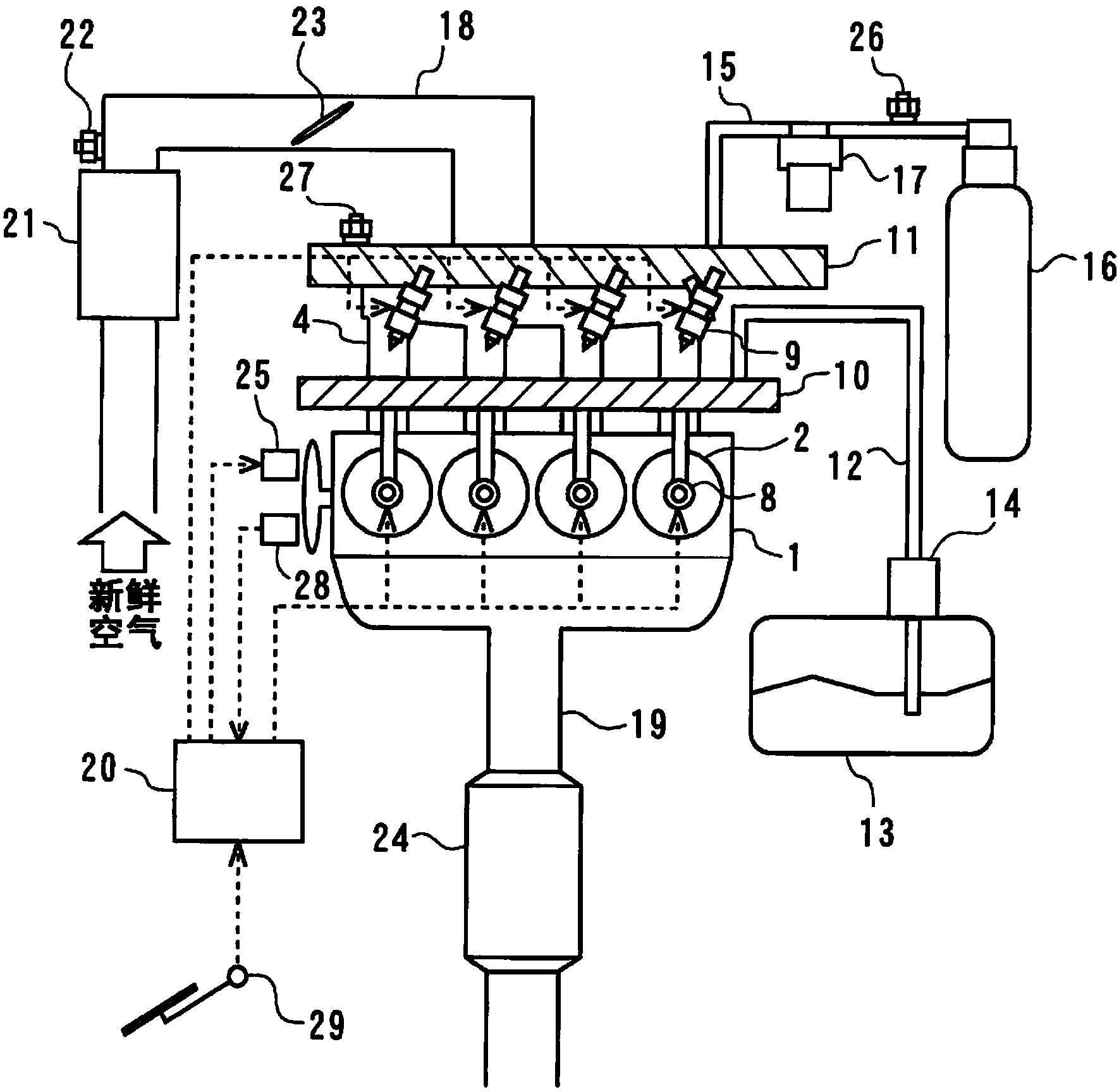

[0034] figure 1 It is a diagram showing a schematic configuration of an internal combustion engine, its fuel system, and an intake and exhaust system according to the present embodiment. The internal combustion engine 1 is an engine for driving a vehicle that can use light oil and compressed natural gas (hereinafter referred to as CNG) as fuel. The internal combustion engine 1 is a compression ignition type engine. The internal combustion engine 1 can be operated by combusting light oil and CNG, and can also be operated by burning only light oil. In addition, in this example, light oil corresponds to the liquid fuel according to the present invention, and CNG corresponds to the gaseous fuel according to the present invention.

[0035] Internal combustion engine 1 has four cylinders 2 . An intake port 4 and an exhaust port (not shown) are connected to an upper combustion chamber in the cylinder 2 . The opening of the intake port 4 to the combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com