Method for preparing medium substrate with heterogeneous dielectric constant and meta material

A dielectric constant and dielectric substrate technology, which is applied in the field of metamaterials, can solve the problems that the dielectric constant is not easy to control, and the material cannot meet the predetermined requirements well, so as to achieve rich functional applications, reduce microwave dielectric loss, and realize The effect of impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

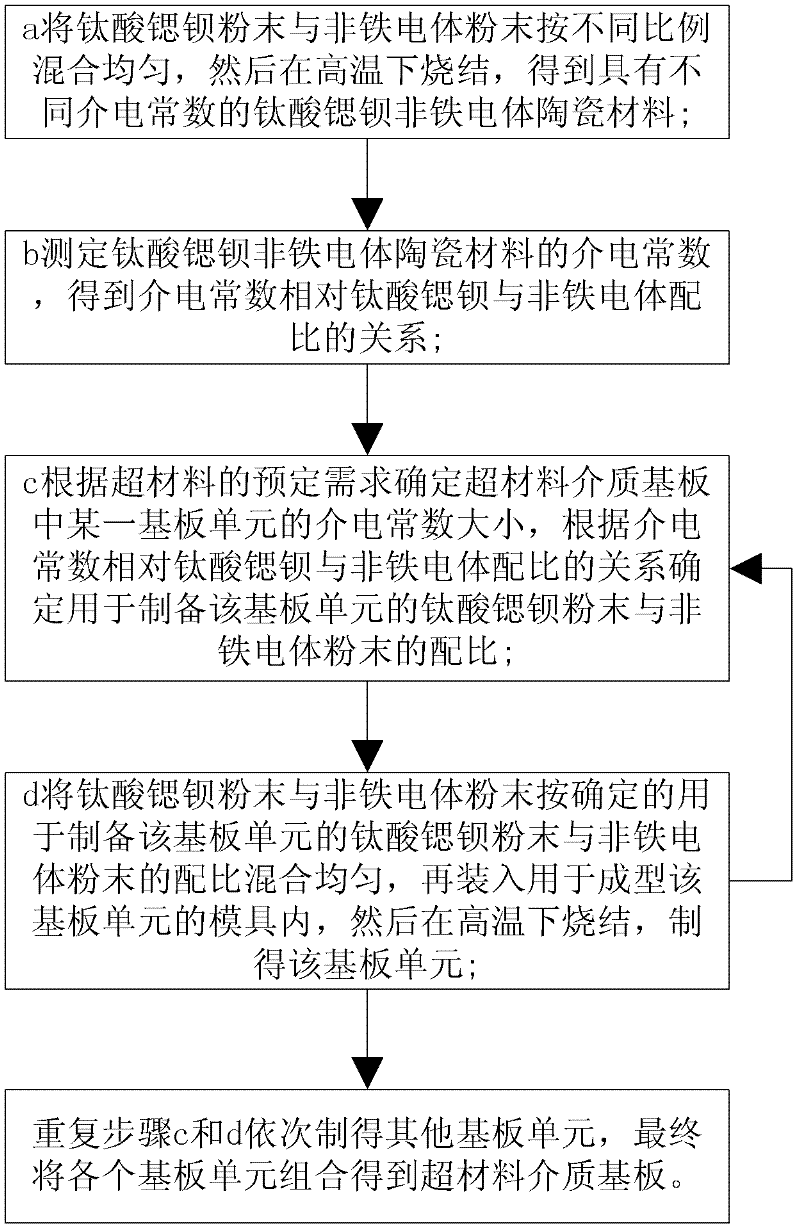

Method used

Image

Examples

Embodiment 1

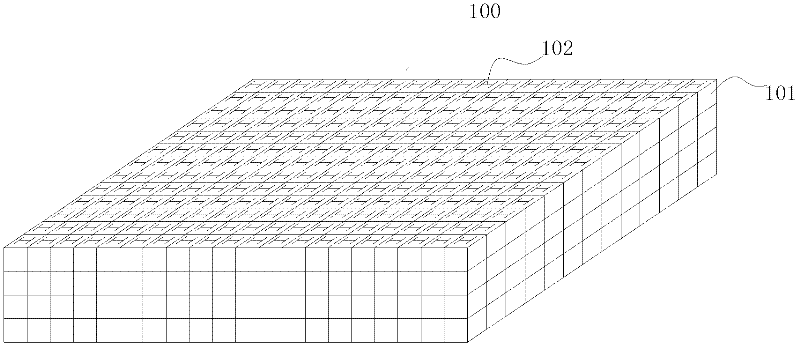

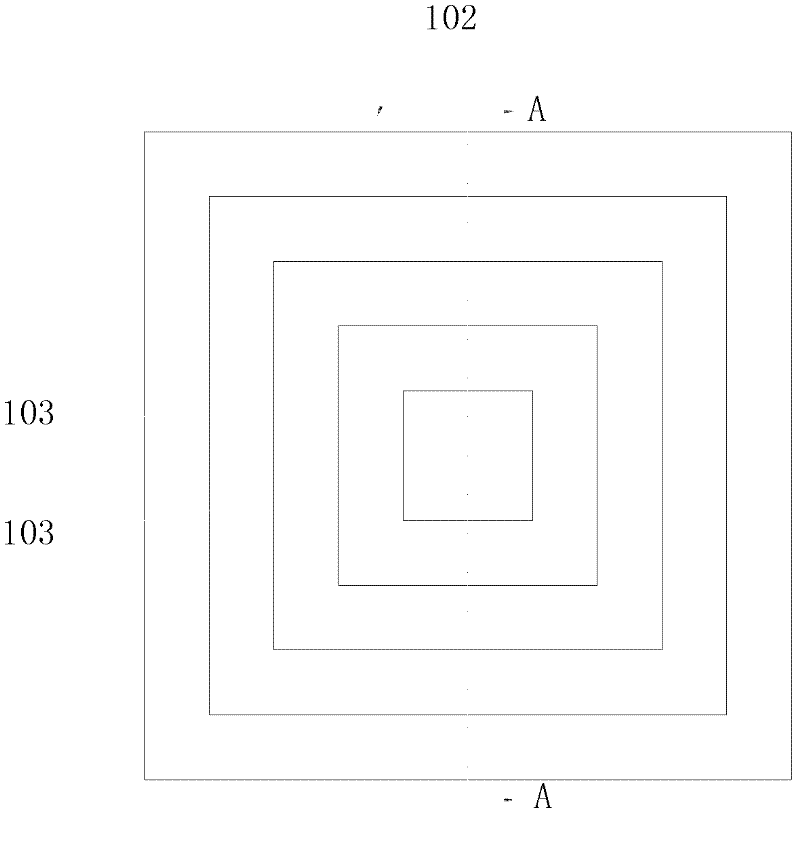

[0038] The dielectric substrate 101 is designed to include a plurality of back-shaped substrate units 103, and the plan view of the dielectric substrate refers to the attached image 3 , Figure 4 for image 3 A-A cross-sectional view of the above, wherein each circular substrate unit 103 adopts different strontium barium titanate magnesia ceramic materials, and the dielectric constants of various strontium barium titanate magnesia ceramic materials increase from the periphery to the center, Figure 4Different packing densities are used to represent different strontium barium titanate magnesia ceramic materials, among which, the larger packing density means larger dielectric constant, and the smaller packing density means smaller dielectric constant. Since the electromagnetic properties of a single basic structural unit are mainly determined by the equivalent permittivity and equivalent magnetic permeability of the basic structural unit, and the equivalent dielectric constant...

Embodiment 2

[0046] As another modification of the present invention, the dielectric substrate 101 is designed to include a plurality of annular substrate units 103, and for a plan view of the dielectric substrate, refer to the attached Figure 5 , Figure 6 for Figure 5 A-A cross-sectional view of FIG. 1 , wherein each annular substrate unit 103 adopts different strontium barium titanate silicon oxide ceramic materials, and the dielectric constants of various strontium barium titanate silicon oxide ceramic materials decrease from the periphery to the center, Figure 6 Different packing densities are used to represent different strontium barium titanate silicon oxide ceramic materials, among which, the packing density is large, the dielectric constant is large, and the packing density is small, the dielectric constant is small. Since the electromagnetic properties of a single basic structural unit are mainly determined by the equivalent permittivity and equivalent magnetic permeability o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com