Yig ferrite material and preparation method

A technology of ferrite material and raw material, applied in the field of YIG ferrite material and its preparation, can solve the problems of expensive raw material, high loss, large line width, etc., and achieve the effect of reducing microwave dielectric loss and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

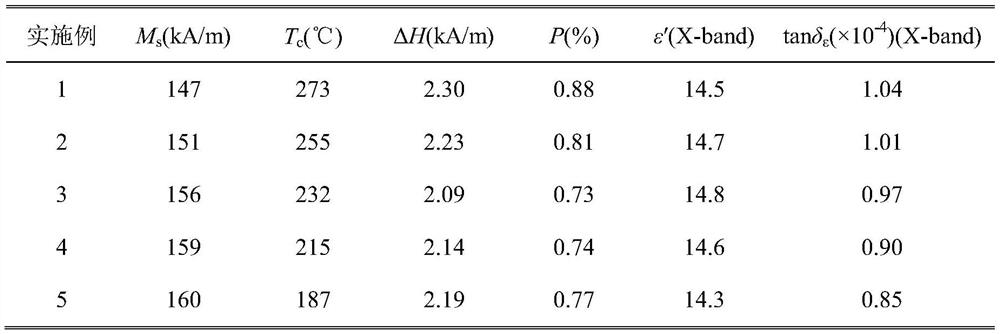

Examples

Embodiment 1~5

[0070] Embodiment 1~5: a kind of preparation method of YIG ferrite material comprises the following steps:

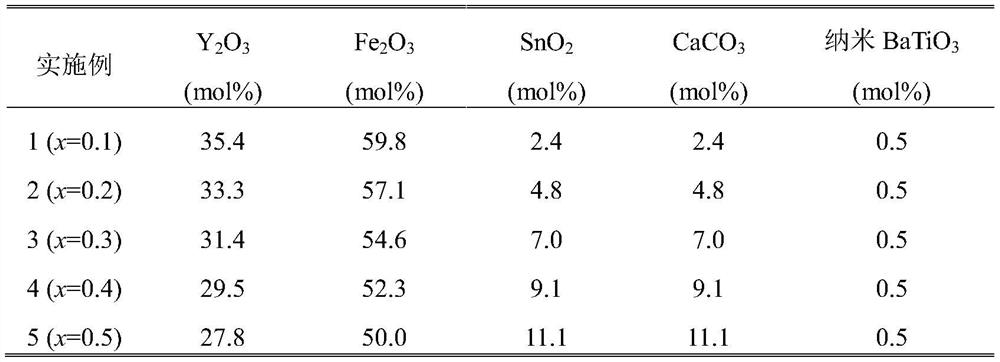

[0071] 1. Formula

[0072] Embodiment 1~5 (x represents molecular formula Y 3-x Ca x Fe 5-x sn x o 12 Medium Sn ion substitution) main formula and nano BaTiO 3 See the table below for the amount of doping:

[0073]

[0074] 2. One ball milling

[0075] Mix the powder prepared according to the proportion in the ball mill evenly for 6 hours;

[0076] 3. Pre-burning

[0077] Dry the ball abrasive obtained in step 2, and pre-fire it in a furnace at 1100°C for 2 hours;

[0078] 4. Doping

[0079] The powder obtained in step 3 is doped by the following weight percentage: 0.20wt% Bi 2 o 3 , 0.05wt% Nb 2 o 5 , 0.10wt% Ta 2 o 5 , 0.50wt% nano BaTiO 3 ;

[0080] 5. Secondary ball milling

[0081] Mix superhard ball milling media with different diameters in the ball mill according to a certain ratio, mix the powder obtained in step 4 according to a certain ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com