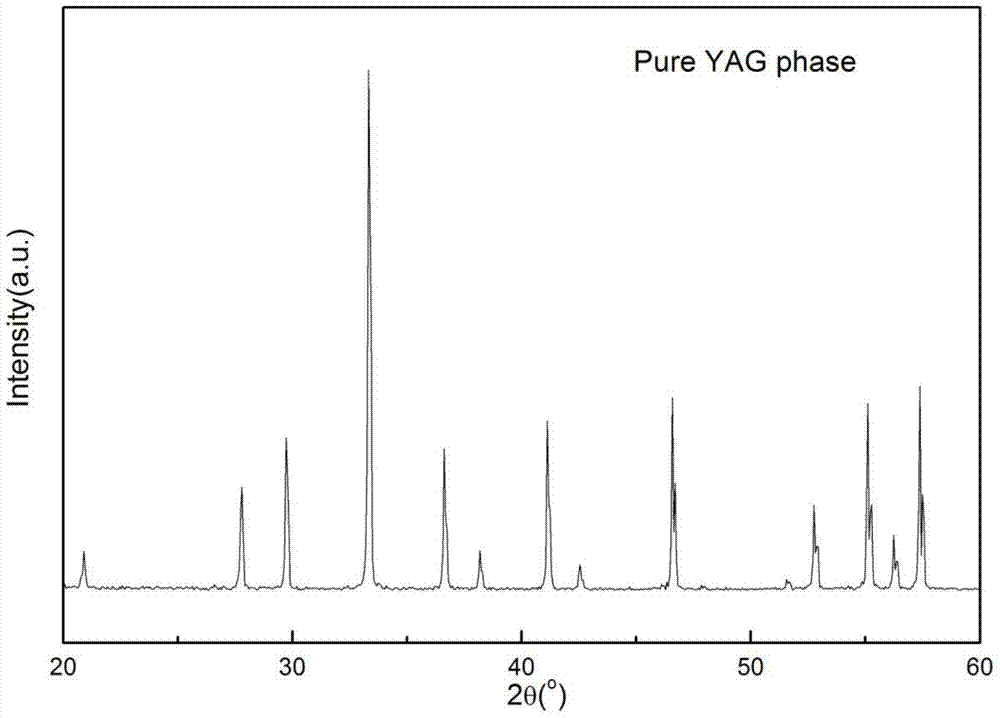

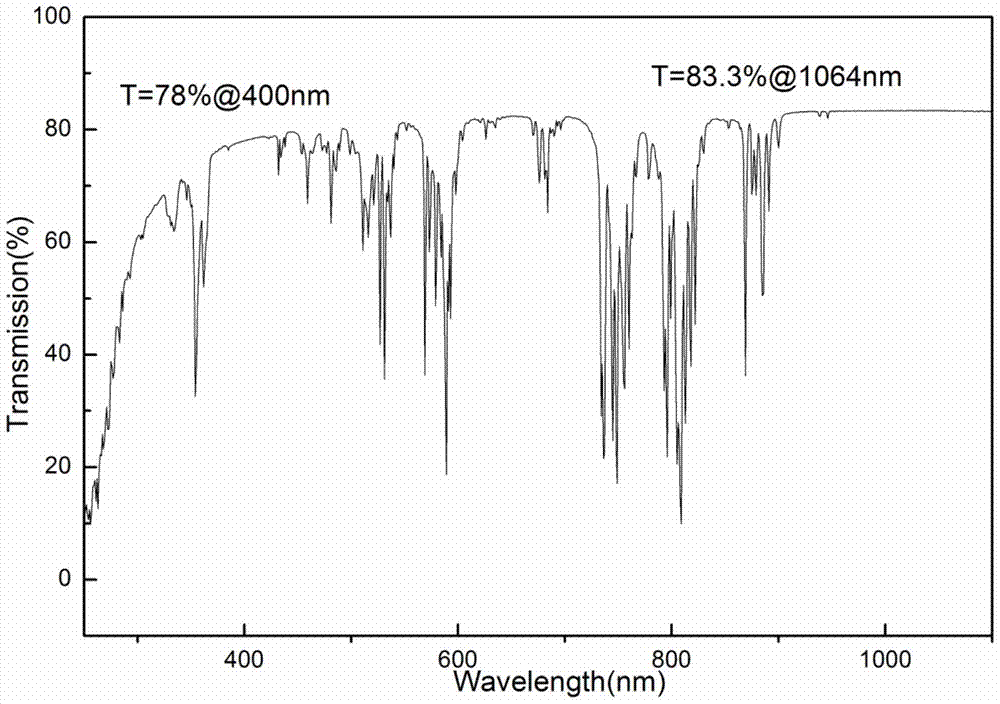

A high-q transparent yag microwave dielectric ceramic material and its application

A microwave dielectric ceramic and microwave dielectric technology, which is applied in the field of electronic information functional materials and devices, can solve the problems of unreported microwave dielectric properties and low dielectric loss, and achieve the promotion of element diffusion and movement, low microwave dielectric loss, The effect of high sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

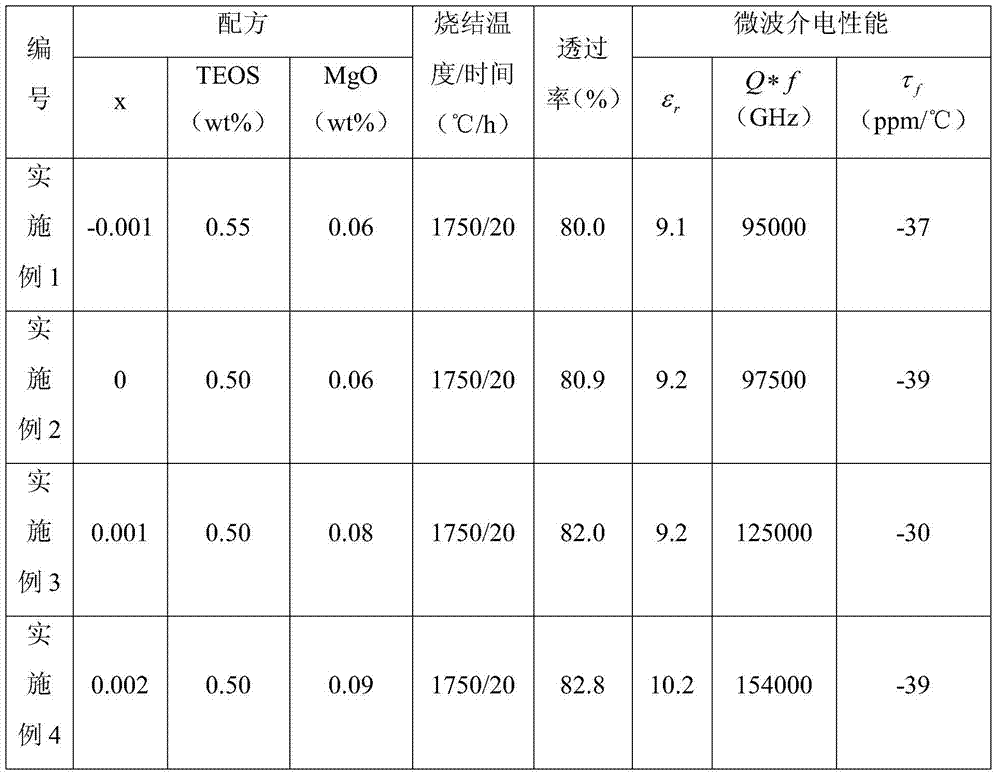

Embodiment 1~9

[0024] The specific implementation steps of making these embodiment high Q transparent YAG microwave dielectric ceramics are as follows:

[0025] (1) Select Al 2 o 3 , Y 2 o 3 , TEOS and Mg(NO 3 ) 2 as the raw material, weigh the raw material according to the design formula: the composition of the base material is Y 3 al 5-x o 12 , where -0.001≤x≤+0.005; the sintering aid is composed of 0.40~0.55wt% TEOS and 0.06~0.10wt% MgO of the total mass of the base material, wherein MgO passes through Mg(NO 3 ) 2 added in the form of an aqueous solution. In the raw material, Al 2 o 3 and Y 2 o 3 The purity of ≥99.99%, Mg(NO 3 ) 2 The purity is ≥99.9%.

[0026] (2) the prepared raw material Al 2 o 3 , Y 2 o 3 , TEOS and Mg(NO 3 ) 2 The aqueous solution was put into a ball mill jar equipped with alumina balls in turn, and then poured into absolute ethanol. Ball milling on a planetary ball mill at a speed of 220r / min for 10 hours; wherein, the mass ratio of YAG raw ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

| frequency temperature coefficient | aaaaa | aaaaa |

| frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com