Whitening sunscreen fabric and processing method thereof

A processing method and fabric technology, applied in the field of whitening and sunscreen fabrics and their processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

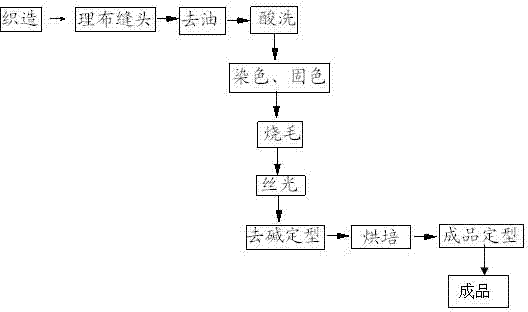

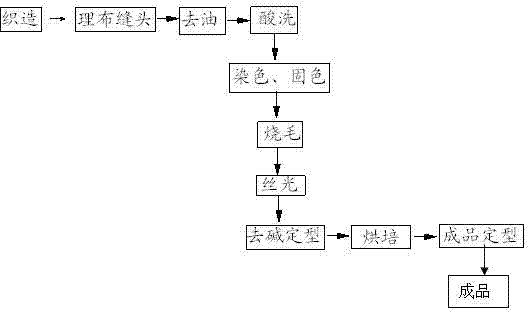

[0022] The raw materials of the fabric are nano-pearl fiber, nano-bamboo carbon fiber, spandex fiber and cotton fiber. The percentage ratio of each component is as follows: 8% nano-pearl fiber, 12% nano-bamboo carbon fiber, 40% spandex fiber, and 45% cotton fiber. The fabric is woven with warp and weft, wherein the percentage ratio of nano-pearl fiber and spandex fiber in the warp is 12:38, and the percentage ratio of nano-bamboo carbon fiber and cotton fiber in the weft is 18:37; The processing process of the fabric is weaving → unscrambling seam → degreasing → pickling → dyeing, color fixing and washing → singeing → mercerizing → alkali removal and setting → baking → final product setting.

[0023] The specific implementation steps are as follows:

[0024] a) Weaving, using a large double-sided knitting machine to produce white gray cloth;

[0025] b) Cloth unscrambling seam, use fabric unscrambling machine and sewing machine to prevent cloth from being scratched and scratc...

Embodiment 2

[0034] The raw materials of the fabric are nano-pearl fiber, nano-bamboo carbon fiber, spandex fiber and cotton fiber. The percentage ratio of each component is as follows: 6% nano-pearl fiber, 14% nano-bamboo carbon fiber, 40% spandex fiber, and 40% cotton fiber. The fabric is woven with warp and weft, wherein the percentage ratio of nano-pearl fiber and spandex fiber in the warp is 12:40, and the percentage ratio of nano-bamboo carbon fiber and cotton fiber in the weft is 18:44; The processing process of the fabric is weaving → unscrambling seam → degreasing → pickling → dyeing, color fixing and washing → singeing → mercerizing → alkali removal and setting → baking → final product setting.

[0035] The specific implementation steps are as follows:

[0036] a) Weaving, using a large double-sided knitting machine to produce white gray cloth;

[0037] b) Cloth unscrambling seam, use fabric unscrambling machine and sewing machine to prevent cloth from being scratched and scratc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com