Methods for forming faucets and fixtures

A faucet and body technology, applied in the field of single metal structure, can solve the problems of expensive, corrosion, oxidation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

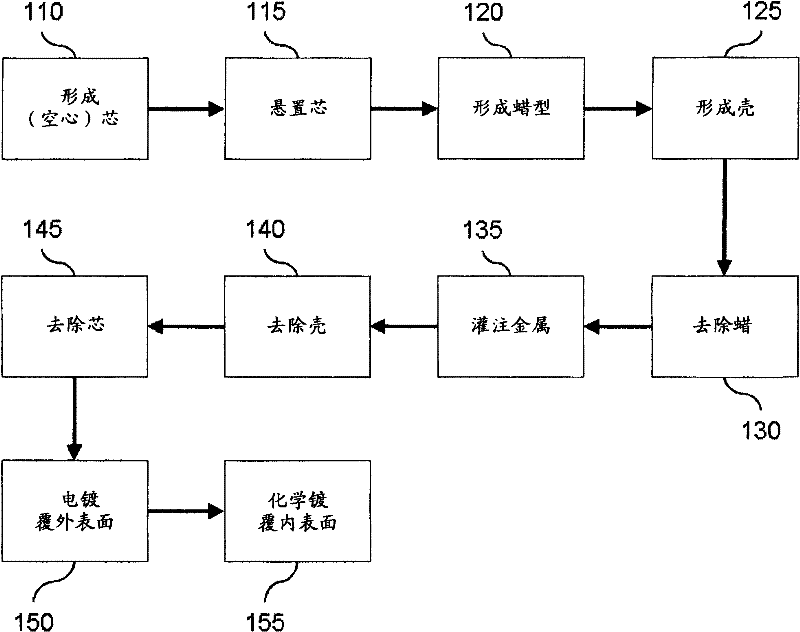

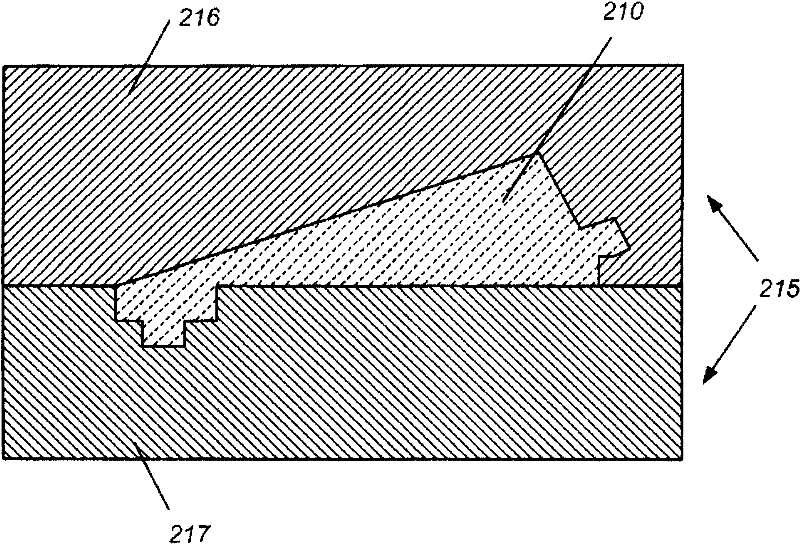

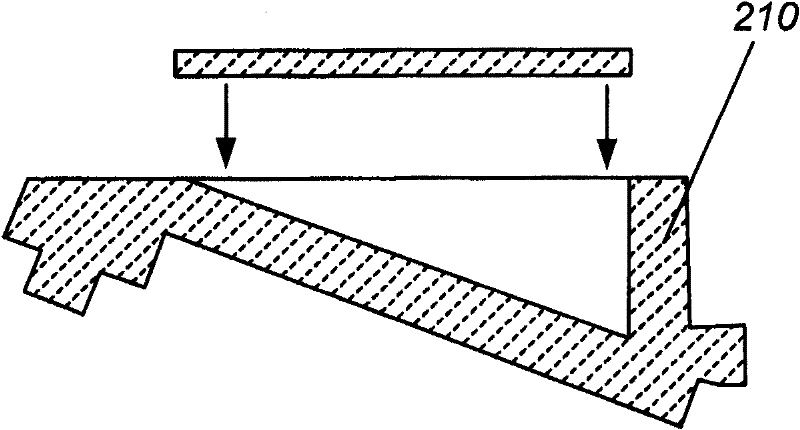

[0029]Typically, soft metal shapes are formed using sand or die casting (carbon steel molds). Casting stainless steel using sand casting is difficult because the sand mold becomes unstable at elevated temperatures (greater than 1475°C). Furthermore, casting stainless steel using steel-to-steel (die) casting is difficult without severe deformation of the tooling components. The investment casting method of embodiments of the present invention advantageously enables the formation of stainless steel appliances without the problems of prior art casting methods.

[0030] The methods of aspects and embodiments of the present invention can be used to form appliances, such as one-piece faucets with multiple chambers. Utensils formed by methods of embodiments of the present invention are substantially non-toxic, patina-free, and comply with environmental regulations and regulatory limits for toxic compounds. The method of the preferred embodiment of the present invention enables the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com