Rotary cutting tool having a cutting edge formed of veined PCD

A technology of rotating cutting tools and cutting tools, which is applied in the field of rotating cutting tools and can solve the problems of cutting edge weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

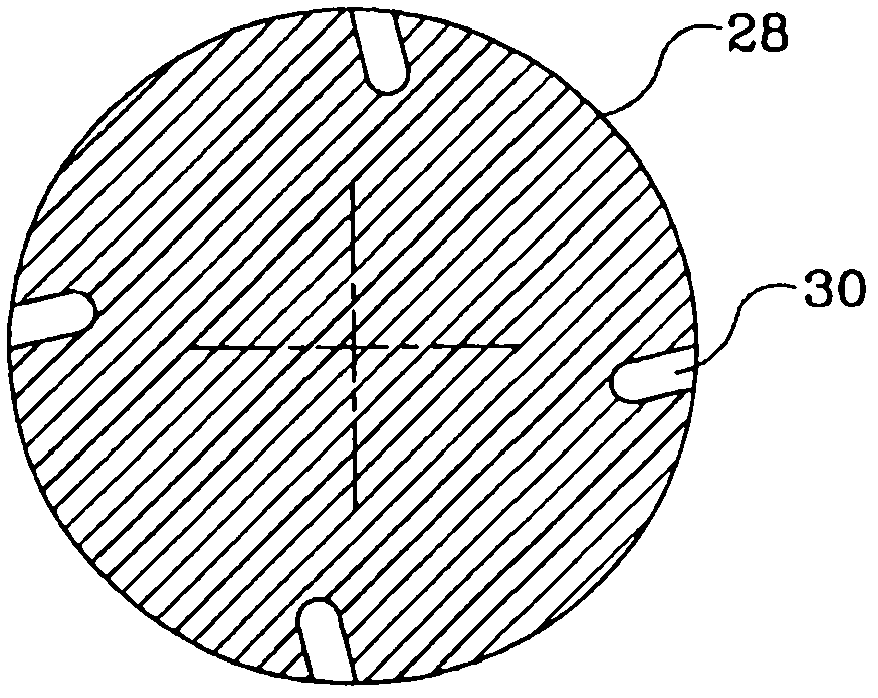

[0029] Figure 4 to Figure 11 Depicts an enlarged cross-sectional view of a textured PCD rotary tool according to the invention, showing different stages of production, the views are along the figure 1 Taken from the same cutting plane indicated by the midline A-A.

[0030] see Figure 4 and Figure 5 , shows a four flute PCD rotary cutter 40 and corresponding blank 42 manufactured according to a first embodiment of the present invention. As seen in a section perpendicular to the tool axis, the face of the tooth is divided into two parts: a first concave portion 44 adjacent to the cutting edge 46 (forming a first curved surface), and adjacent to the tooth root 50. And a second recessed portion 48 adjoining the first portion 44 (constituting a second curved surface). The TC blank 42 is provided with grooves 52 formed with a leading face 54 corresponding to the shape of the first recessed portion 44 of the cutter 40 . In some embodiments, the first recessed portion 44 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com