Abrasive article having a line of weakness

A technology of products and grinding discs, applied in abrasives, manufacturing tools, laser welding equipment, etc., can solve the problems of expensive and difficult to obtain other products, and achieve the effect of easy distribution and economical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

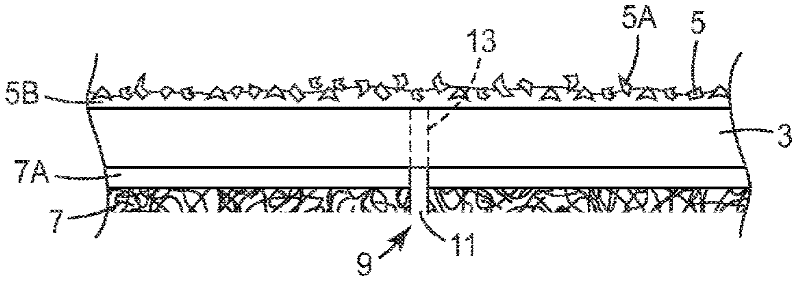

[0028] Figures 1 to 3 The abrasive article 1 shown in is a rectangular coated abrasive sheet. Product 1 comprises a plurality of layers, mainly has (referring to image 3 ) a backing layer 3, an abrasive coating 5 on one side of the backing layer, and an attachment layer 7 on the other side of the backing layer.

[0029] Backing layer 3 comprises any sheet material known to be suitable for use in coated abrasive articles, and may be a multilayer material. Suitable materials include paper, film, cloth and foam of appropriate thickness.

[0030] The abrasive coating 5 comprises any suitable abrasive particles 5A in any suitable resin matrix 5B that acts to bond the particles to the backing layer 3 . Abrasive particles 5A may be of any material and size known to be suitable for use in coated abrasive articles. The resin matrix 5B of the abrasive coating 5 may comprise a conventional make with abrasive grains at least partially embedded therein, and optionally a conventional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com