Main brake cylinder and method for operating a main brake cylinder

A master brake cylinder, working technology, applied in the direction of braking action starting device, brake transmission device, brake, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

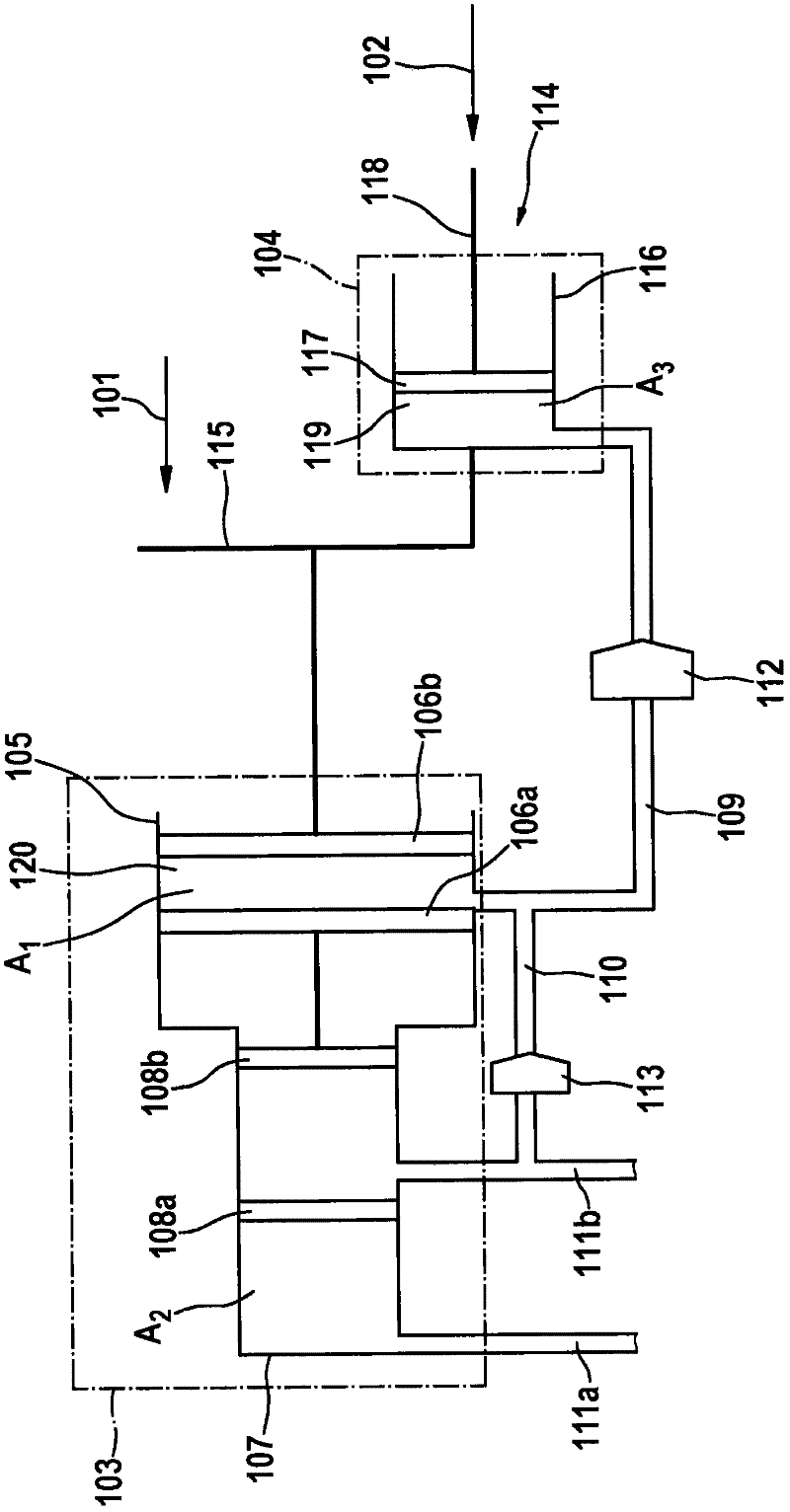

[0034] In a preferred embodiment, the overall brake system consists of a conventional hydraulic part (including, for example, ESP, ABS components) and a further part. For the sake of example, it is assumed that a further partial contribution to the braking effect of the overall braking system is due to the regenerative braking system and is produced by the generator torque. The conventional part of the braking system includes an actuating device 114 via which the human power of the driver 102 can be introduced into the braking system. This driver effort can be combined with an auxiliary force 101 , for example from a controllable brake booster, at a coupling element 115 , for example at a reaction disc. The controllable brake booster can be both an electromechanical brake booster and a controllable vacuum brake booster with electrically actuated valves, but other embodiments are also conceivable. In a conventional hydraulic brake system, the coupling element 115 transmits the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com