Method For Correcting The Temperature Of A Force Measuring Apparatus And Force Measuring Apparatus

A technology for measuring equipment and temperature correction, applied in the direction of weighing equipment testing/calibration, weighing equipment using electromagnetic balance, weighing equipment using elastically deformable parts, etc., can solve non-representative, dependent, temperature sensor installation and adjustment problems, to achieve the effect of simple design, low-cost design, and accurate temperature compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

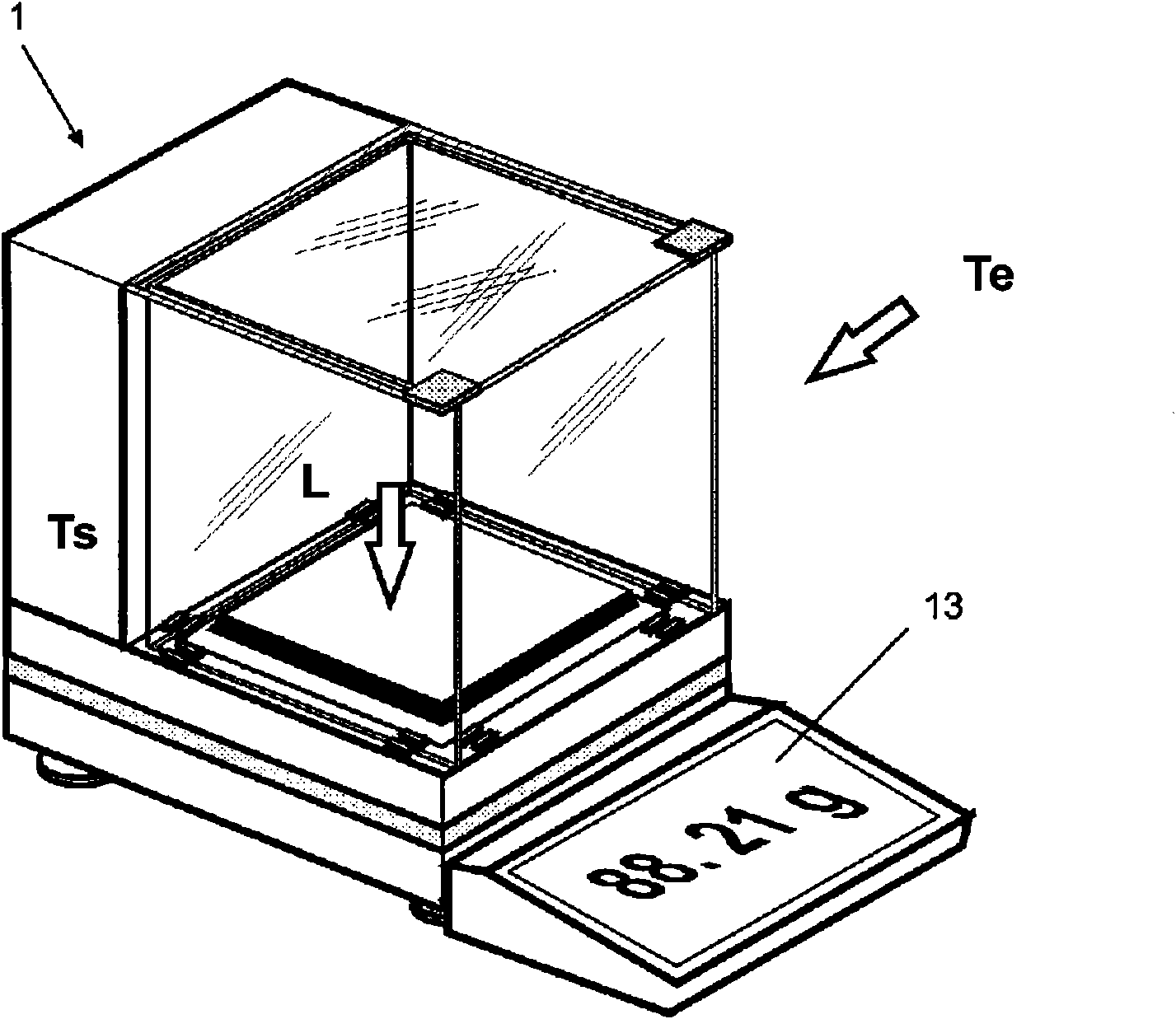

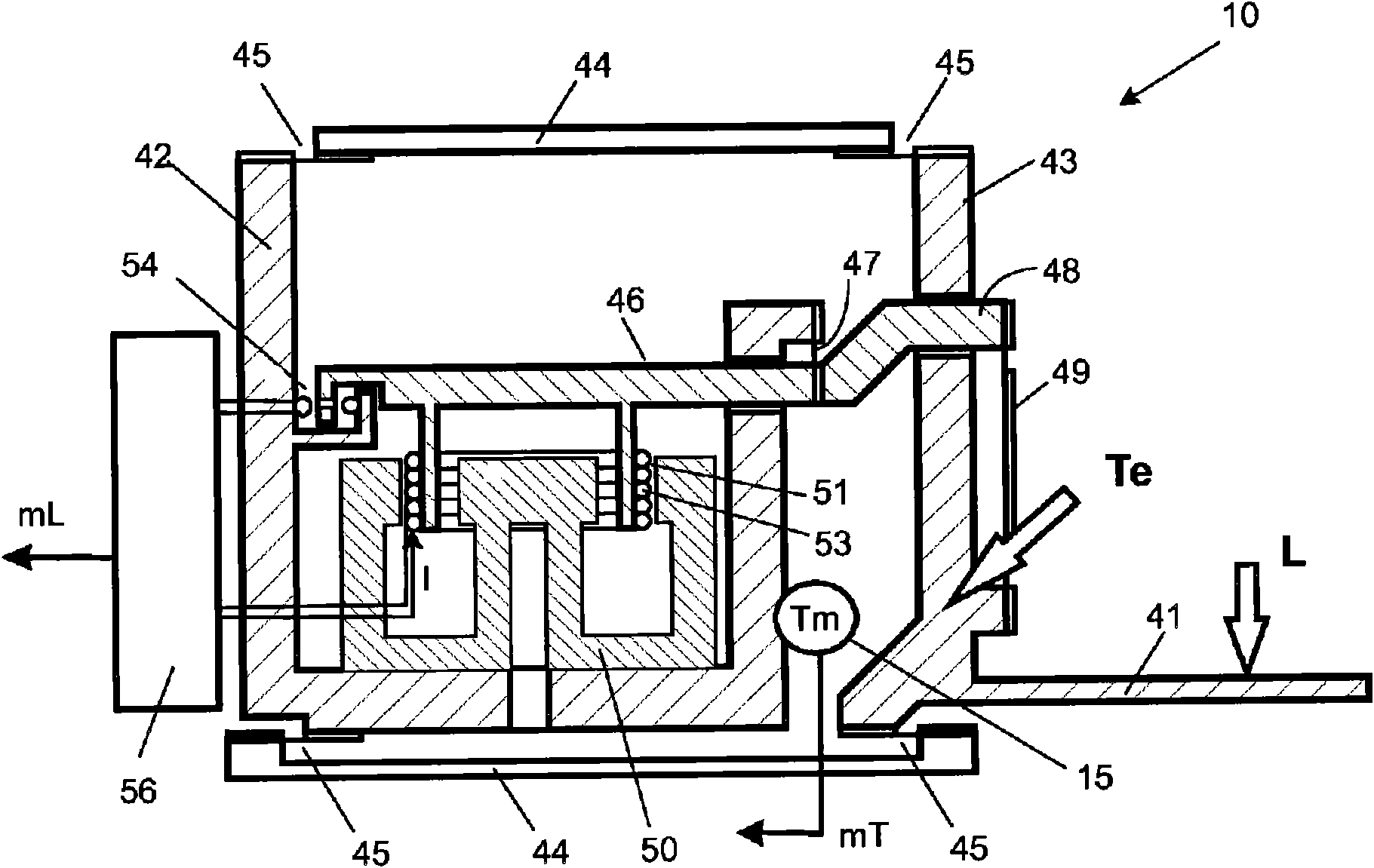

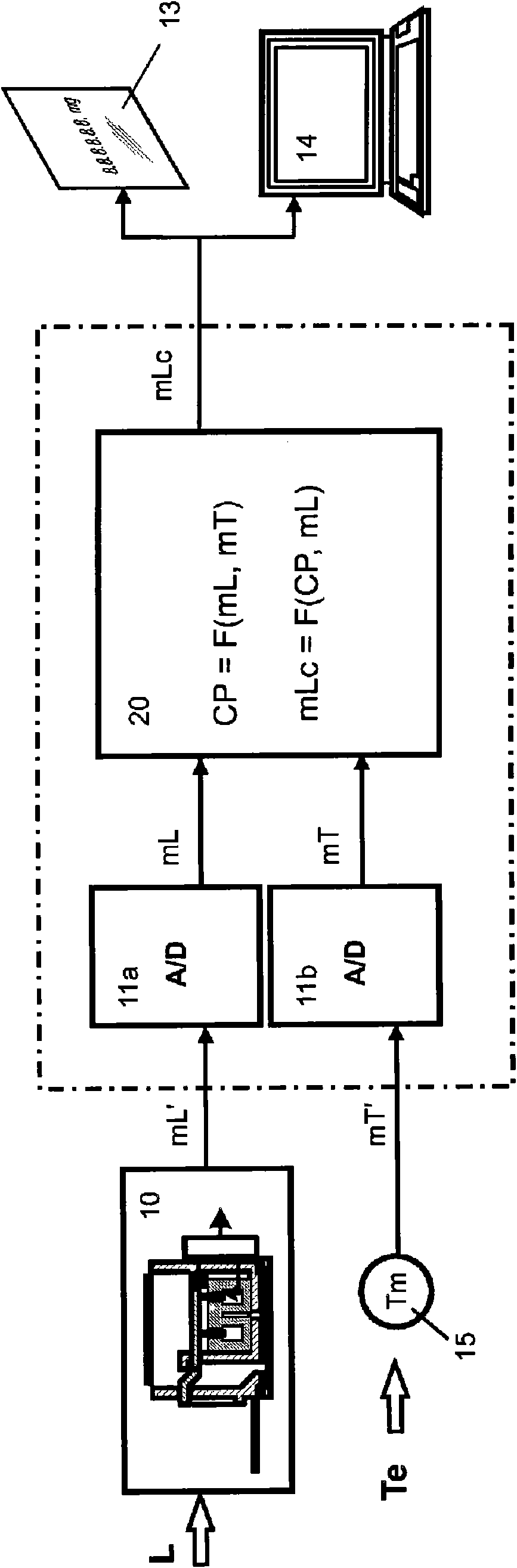

[0065] figure 1 A balance 1 is depicted as a typical example, wherein a load L acting on the balance 1 is symbolically indicated. In response, a compensating force F acting against the input load L is developed. Also symbolically indicated is the ambient temperature Te, which acts on the balance from the outside and has a significant influence on the accuracy and stability of the measurement. On the one hand, the measured value determined by the balance varies as a function of the load L, but it also varies depending on the ambient temperature Te and in response to the effect of the system temperature Ts acting inside the force measuring device.

[0066] As will be described in the following paragraphs, the system temperature Ts may deviate from the ambient temperature Te for various reasons. For example, during the generation of the compensating force, power is dissipated in the interior space of the balance, which causes an increase in the temperature Ts of the system. Ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com