Supporting device and light exposure device

A technology of supporting device and moving parts, applied in photolithography process exposure device, microlithography exposure equipment, optics, etc., can solve the problems of performance error, unstable table position, unable to obtain positioning reproducibility, etc., to achieve a stable position Accuracy, effect of suppressing shape change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

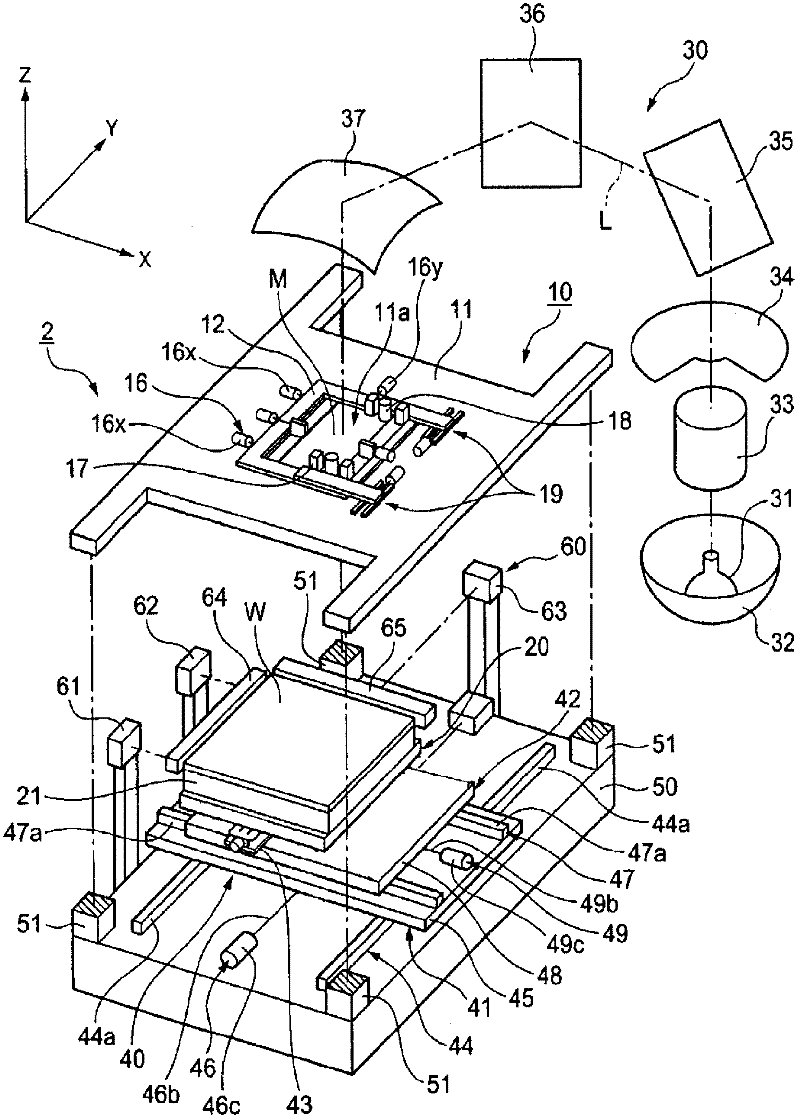

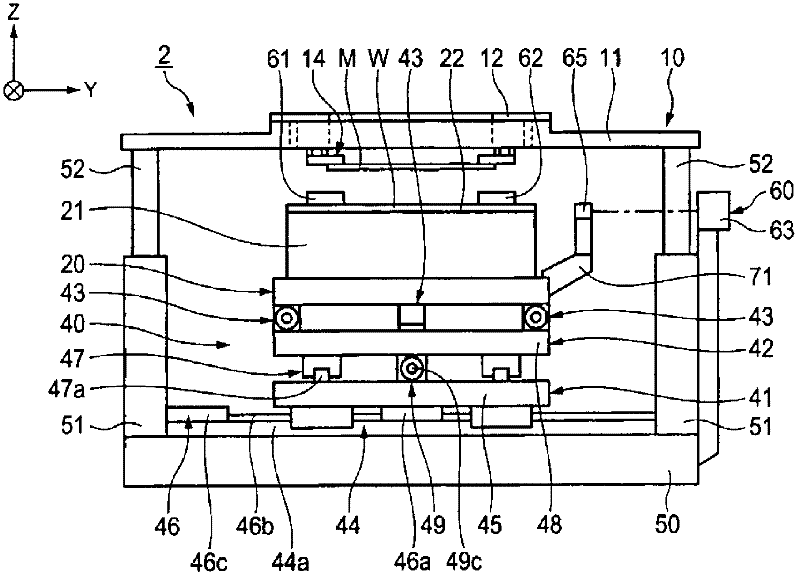

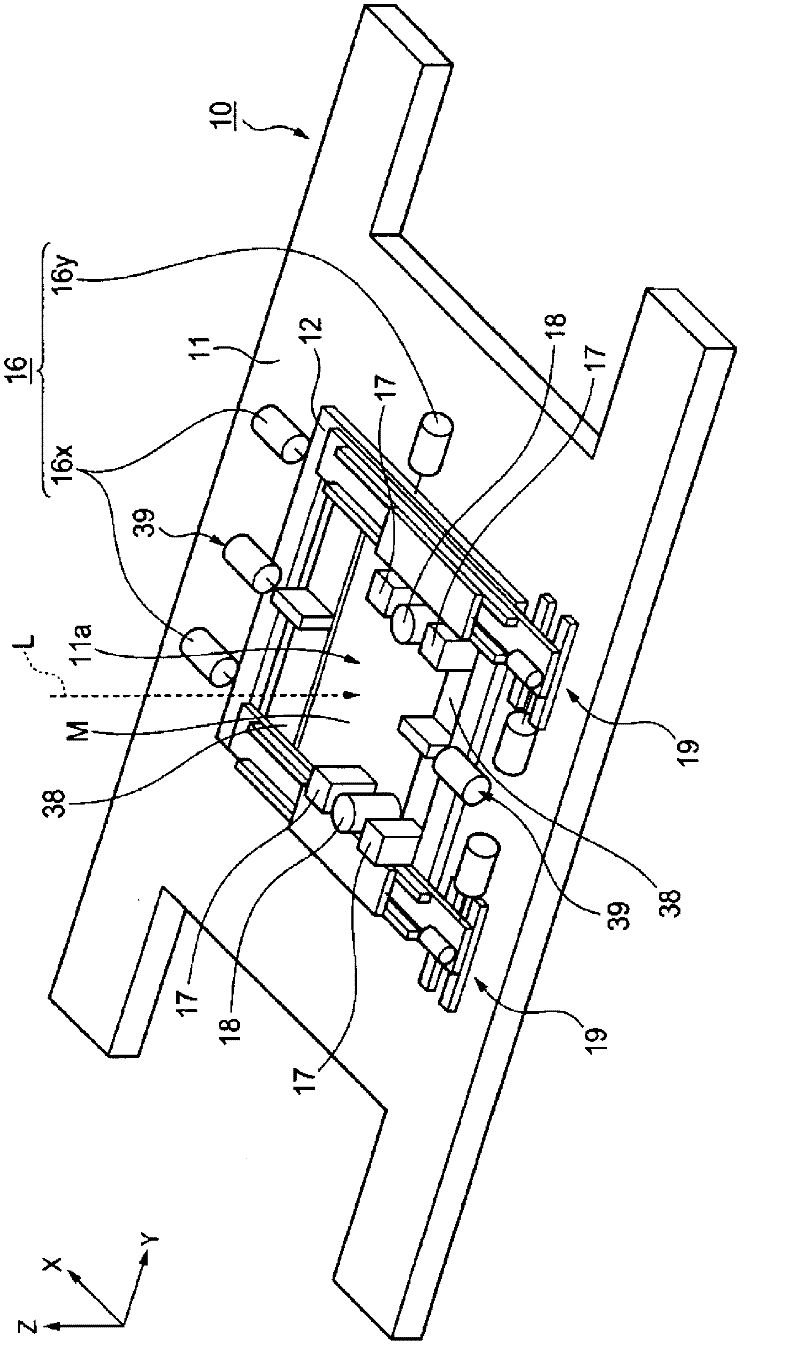

[0023] Next, an exposure unit using the support device according to the present invention will be described in detail with reference to the drawings. Here, let the Z-axis direction be the up-down direction, and let the X-axis direction and the Y-axis direction be the horizontal direction.

[0024] The exposure unit has: a first proximity exposure device body for exposing the first layer; a second proximity exposure device body for exposing the second layer; a third proximity exposure device body for exposing the third layer; and a body for exposing the fourth layer. The fourth is close to the main body of the exposure device. Here, the first to fourth proximity exposure apparatus main bodies only need to have different suction surfaces of the substrate holding parts described later, so only the first proximity exposure apparatus main body 2 will be described in detail below, and other descriptions will be given. Both are omitted.

[0025] Such as figure 1 As shown, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com