Lead frame and a method for producing piezoelectric vibrator, a resin mold construction of a piezoelectric vibrator

A piezoelectric vibrator and lead frame technology, which is applied in the field of radio clocks, can solve the problems of insufficient bending of the outer lead 3, elastic deformation of the outer lead, impossible alignment of the required joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

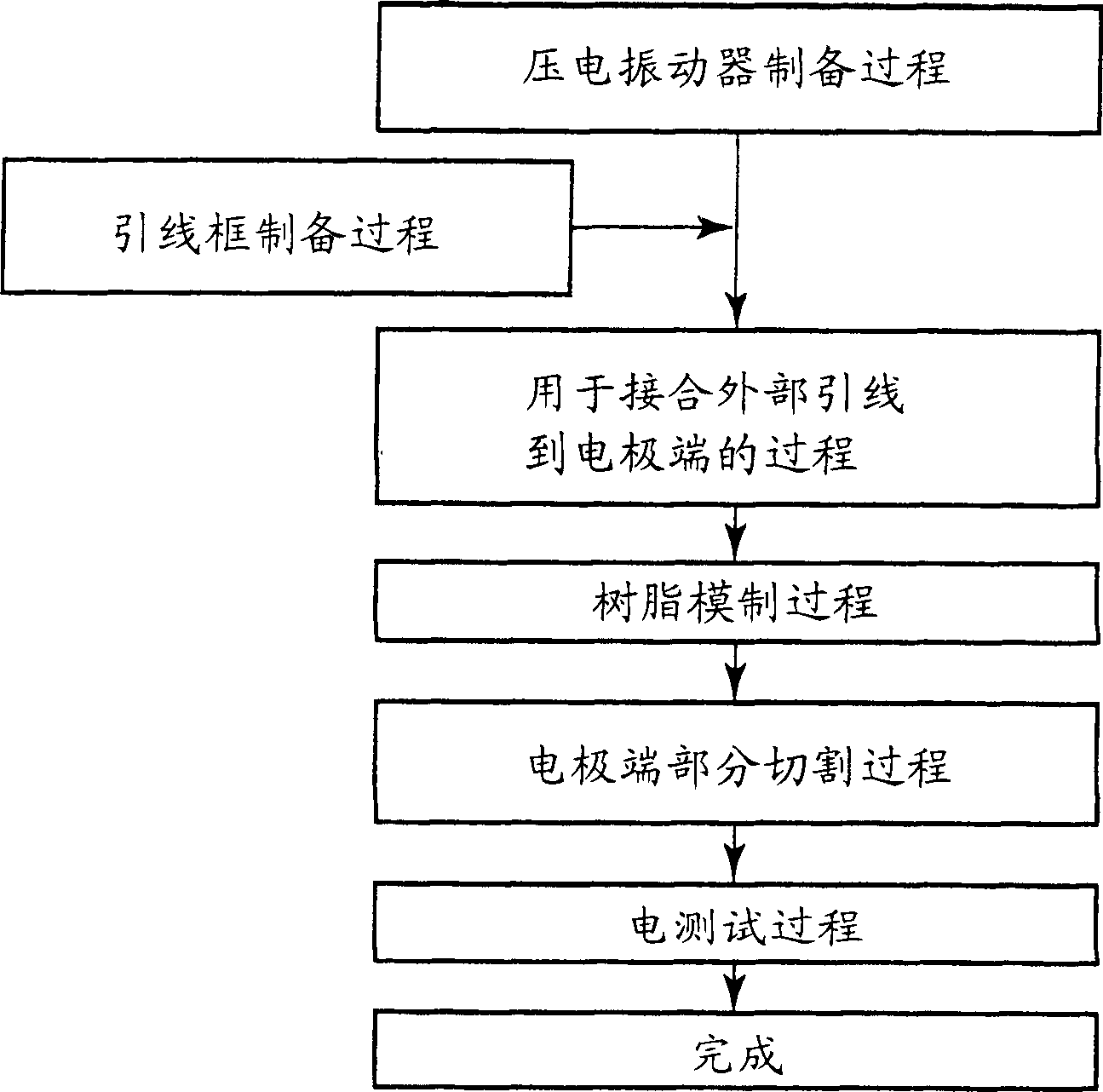

[0183] figure 1 is a flowchart briefly showing the manufacturing process of the surface mount type piezoelectric vibrator according to the first embodiment of the present invention. In order to facilitate understanding of this embodiment, the following process will be described as follows:

[0184] 1. Piezoelectric vibrator preparation process: After cutting and polishing, a quartz crystal sheet is formed from a piezoelectric material. An electrode film required for each quartz crystal plate used as a piezoelectric vibrator is formed on each of its front and rear surfaces, thereby forming a piezoelectric vibrating plate. A piezoelectric vibrating piece is bonded to each sealing end, wherein the sealing end is connected to a dynamic loading plate for the piezoelectric vibrator. The dynamic splint is prepared for the finished piezoelectric vibrator, which are all sealed in the sealed tube.

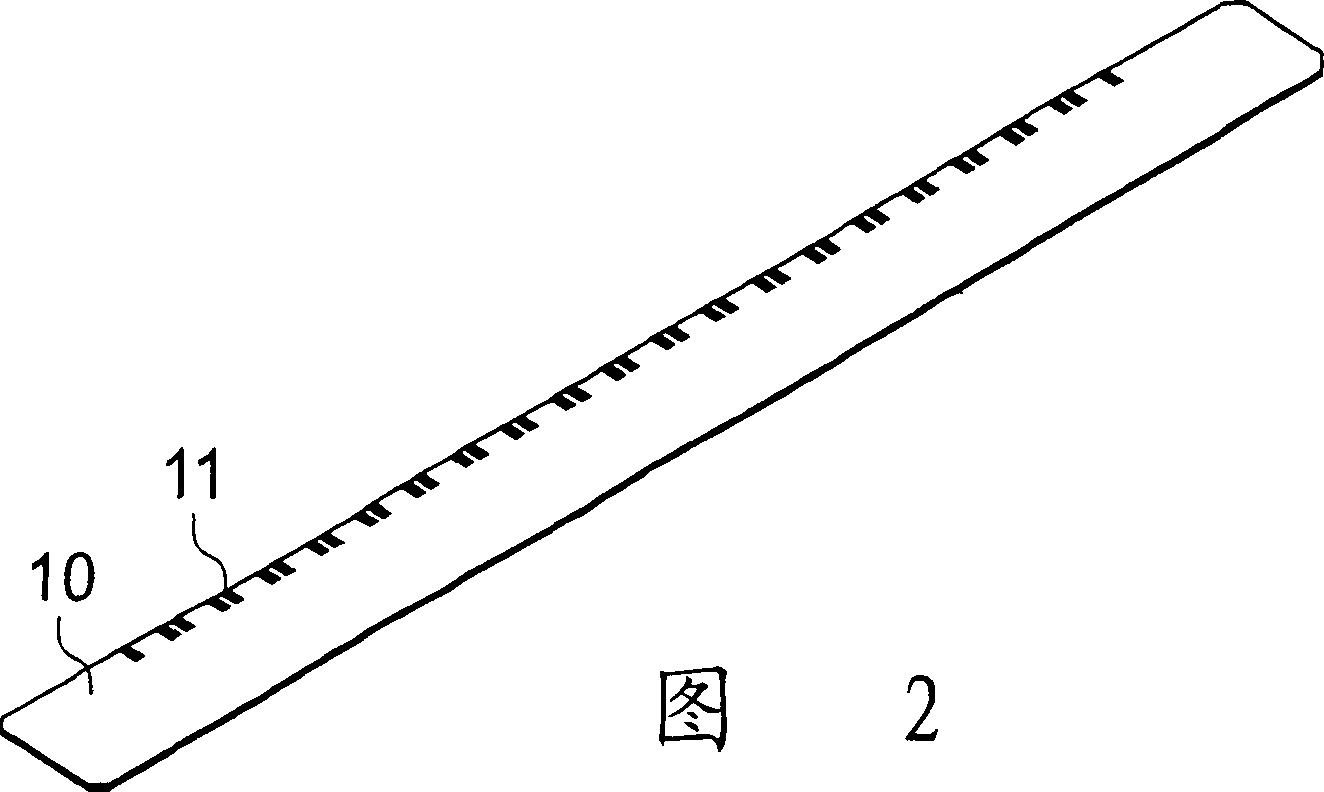

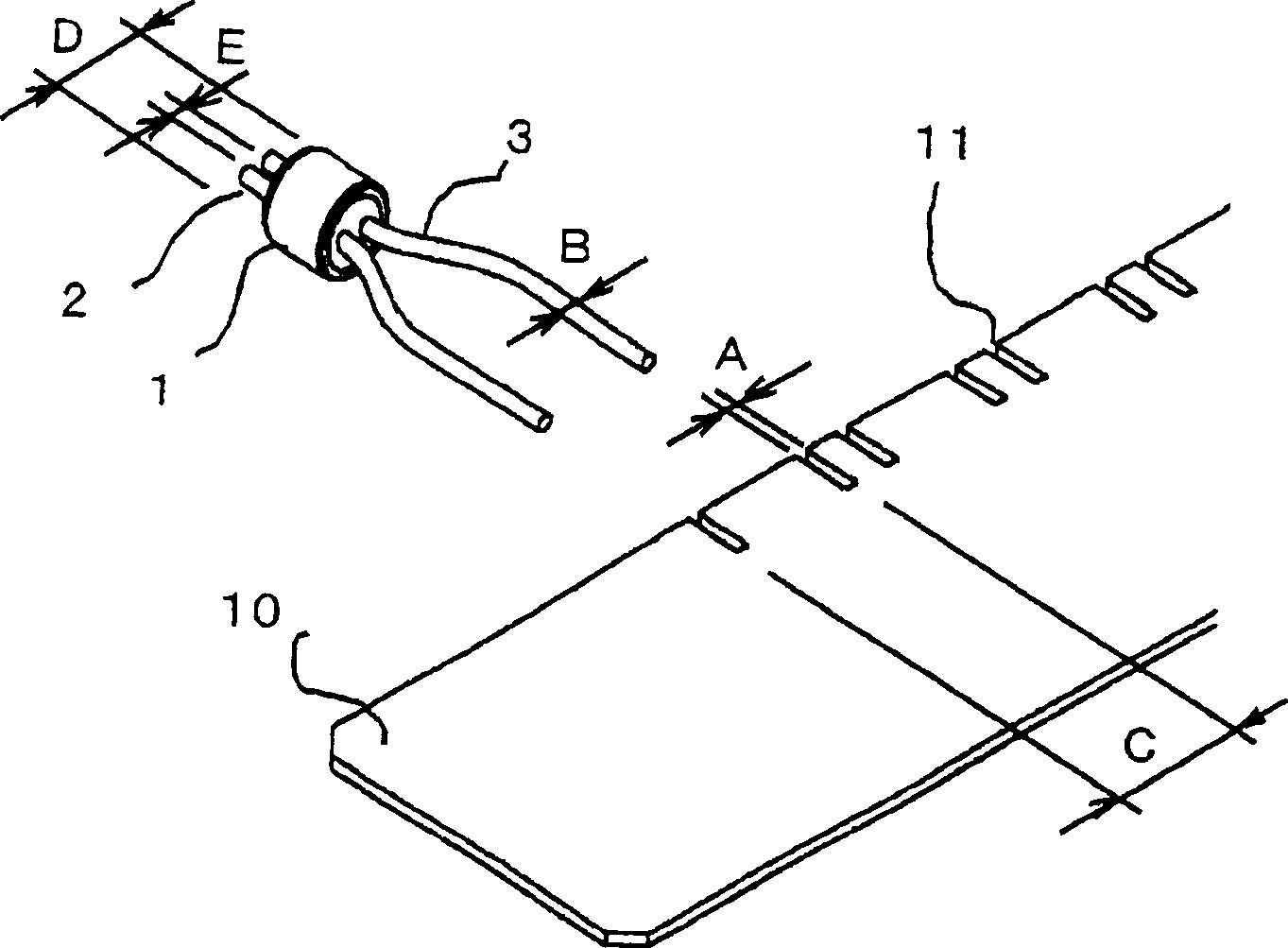

[0185] 2. Lead frame preparation process:

[0186] A lead frame formed with electro...

no. 2 example

[0302] A second embodiment according to the present invention will be described below with reference to FIG. 28 . FIG. 28 is a schematic pattern diagram of an example structure of a tuning-fork type quartz crystal oscillator according to a second embodiment of the present invention. The tuning fork type quartz crystal oscillator 90 uses the above-mentioned surface mount type piezoelectric vibrator 31 as an oscillating plate, and is connected to an integrated circuit.

[0303] In FIG. 28 , a surface mount type piezoelectric vibrator 31 is provided in a predetermined position on a substrate 92 , and an integrated circuit for an oscillator denoted by reference numeral 93 abuts against the surface mount type piezoelectric vibrator 31 . Electronic components 94 such as capacitors are also mounted. These components are electrically connected together by an unillustrated wiring pattern. The mechanical vibration of the vibrating plate of the surface mount type piezoelectric vibrator...

no. 3 example

[0306] A third embodiment of the present invention will be described below. The third embodiment is an example of an electronic unit using a surface mount type piezoelectric vibrator 31 manufactured by the method according to the present invention, wherein the vibrator is connected to a timekeeping section. As an example of an electronic unit, a preferred embodiment of a portable information unit represented by a mobile phone will be described below with reference to the accompanying drawings. Figure 29 is a block diagram functionally showing the structure of the portable information unit according to this embodiment.

[0307] The portable information unit 100 is an improved and improved version of a wrist watch made in the prior art. The portable information unit is similar in appearance to a wristwatch. The portable information unit has a liquid crystal display instead of a clock dial, which shows the current time on the screen. When the portable information unit is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com