Housing For A Ballast

A ballast and housing technology, which is applied in the field of ballast housings, can solve the problems that the housing cannot be directly fixed and cannot realize the sealing of headlights, etc., and achieve the effect of protecting corrosion, damage and touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

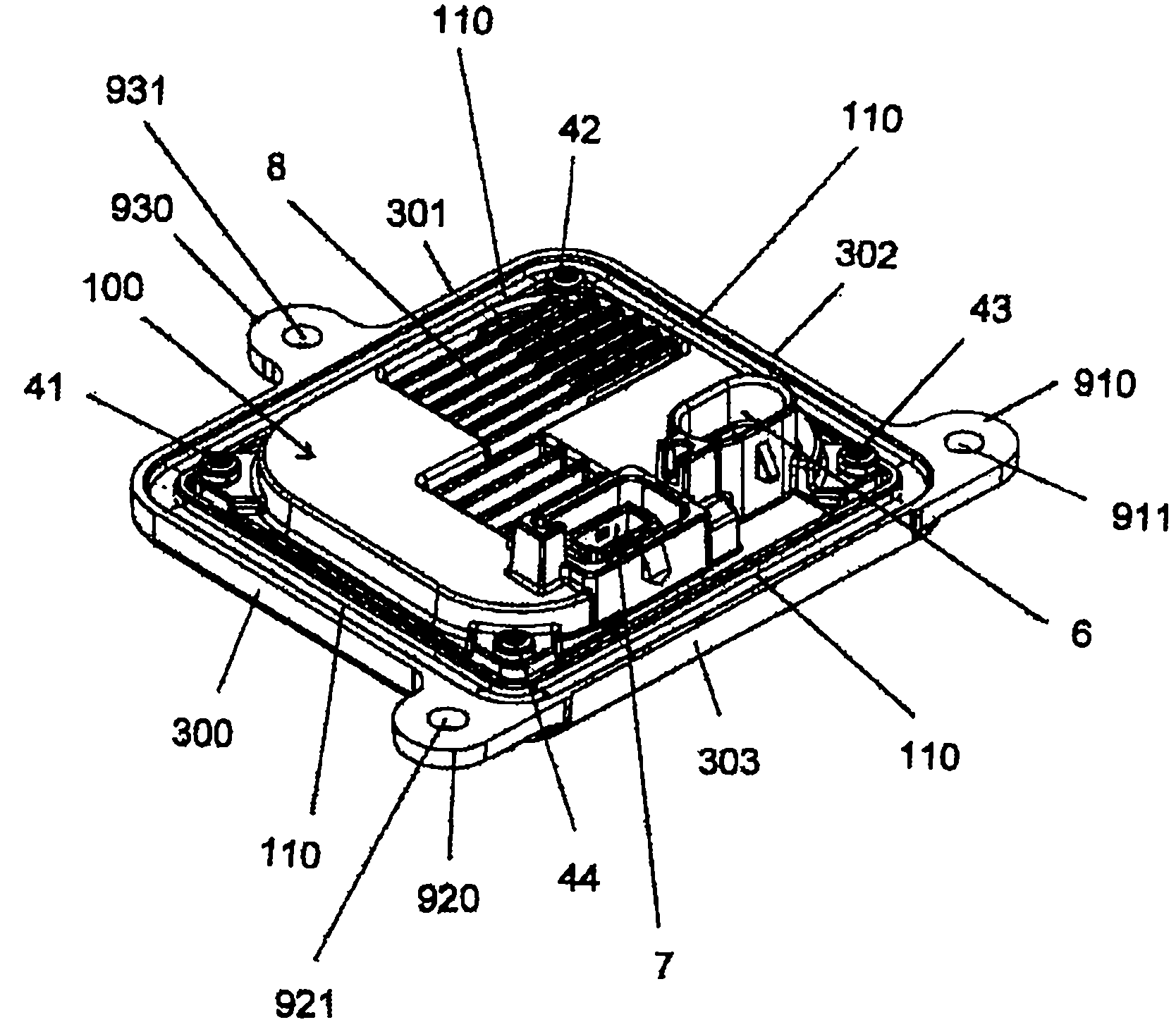

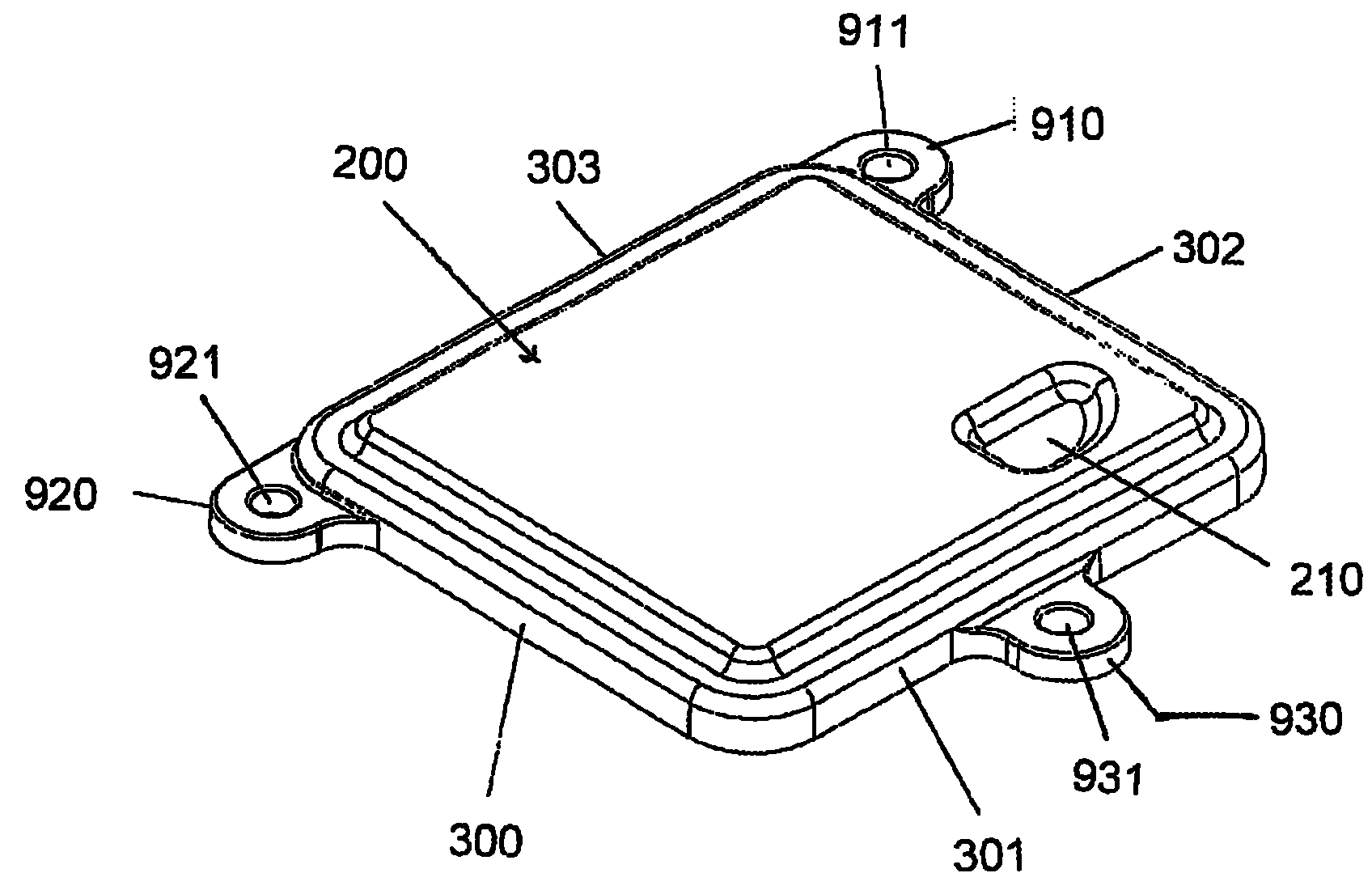

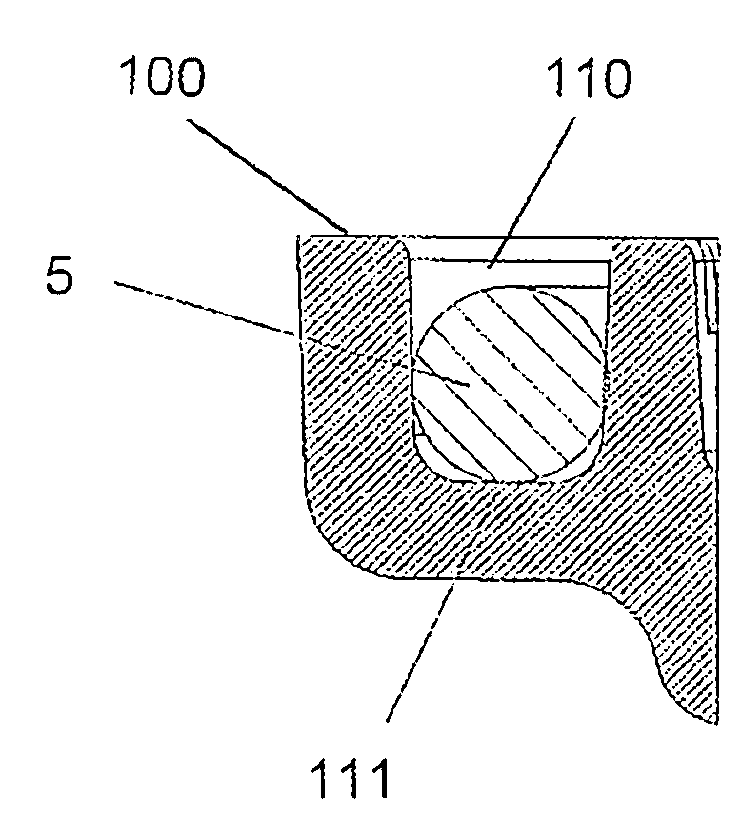

[0019] exist figure 1 and 2 A housing according to a preferred embodiment of the present invention is shown in . The housing is basically formed as a cuboid and is very flat, approximately in the shape of a sheet. The housing has a large surface 200 and four side walls 300 , 301 , 302 , 303 . The above-mentioned six faces of the housing form a closed inner cavity, in which the components for driving the ballast of the metal halide vapor high-pressure discharge lamp are arranged on a mounting plate (not shown), the metal halide Vapor high-pressure discharge lamps are used as light sources in vehicle headlights. The mounting plate extends parallel to the front 100 and rear 200 of the housing. The edges between the side walls 300 , 301 , 302 , 303 are rounded. The housing consists of two magnesium die-cast parts connected to each other by means of screws 41 , 42 , 43 , 44 . The housing has a recess 110 running annularly on the outside of the front side 100 parallel to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com