Heat recycling backflow welding machine

A reflow soldering machine and heat energy technology, applied in electric heating devices, welding equipment, assembling printed circuits with electrical components, etc., can solve the problems of affecting PCB cooling, power consumption, energy waste, etc., to reduce power consumption and simple structure. , Reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

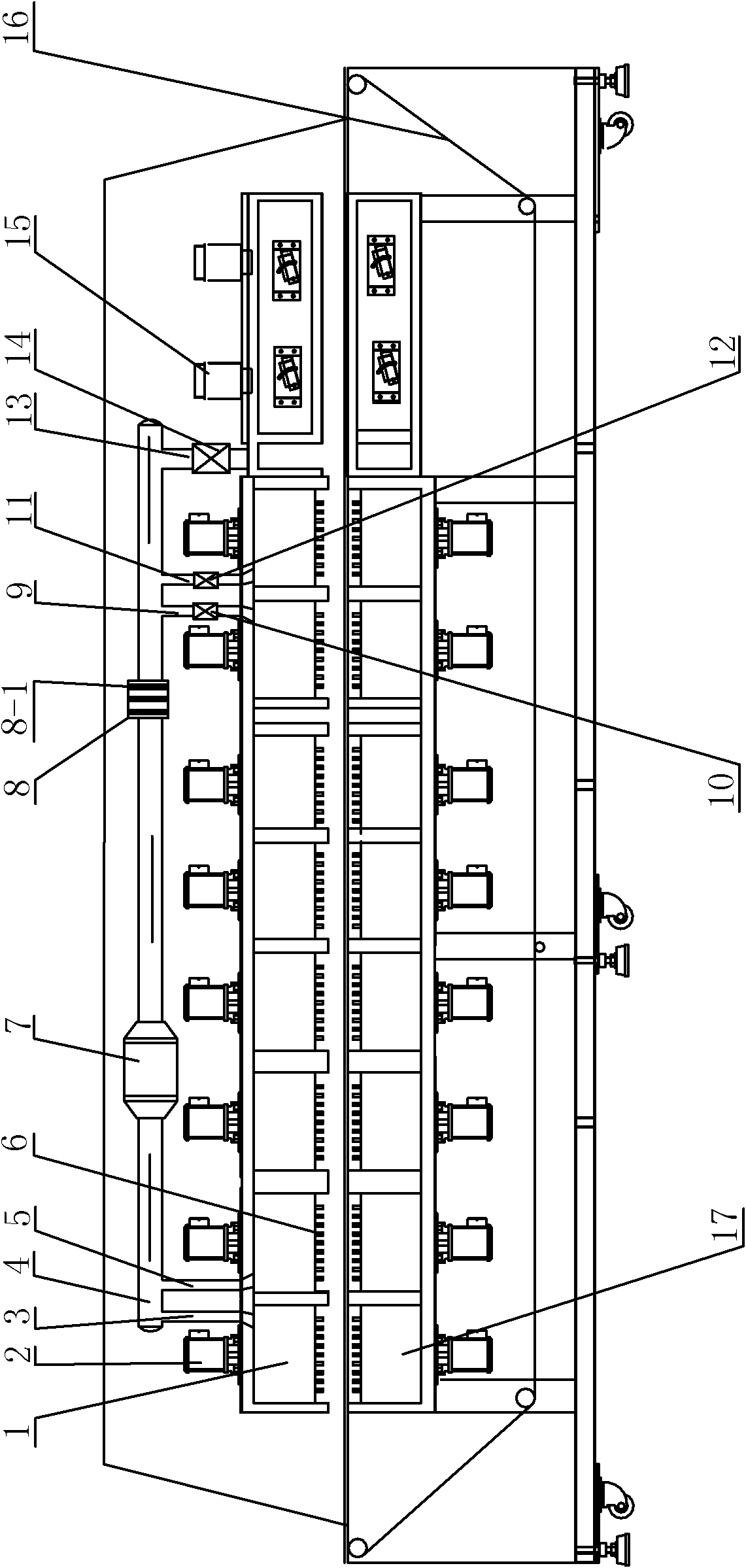

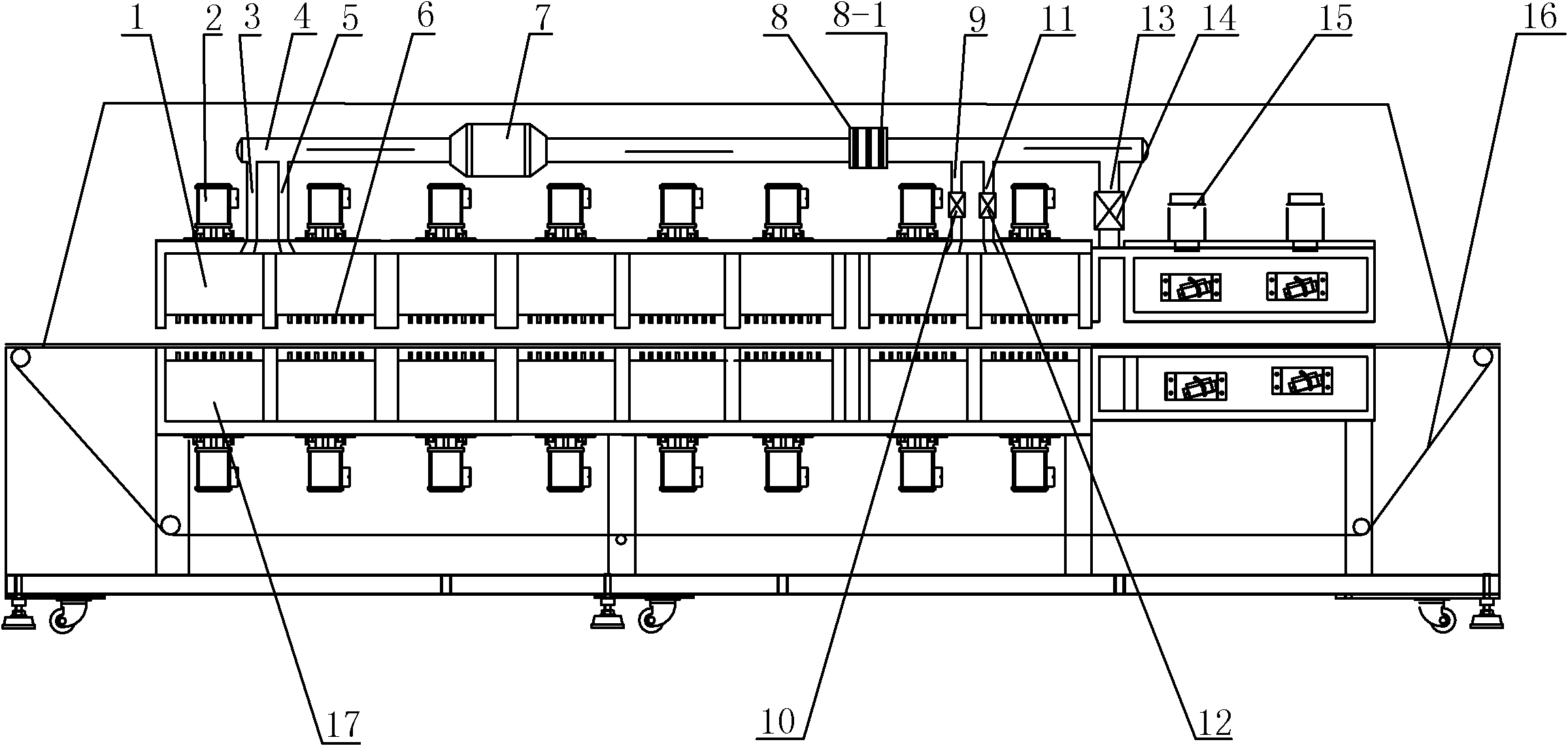

[0022] Such as figure 1 The heat recycling reflow soldering machine shown includes a preheating zone, a welding zone, and a cooling zone arranged sequentially from left to right, and is used to drive the PCB through the preheating zone, the welding zone, and the cooling zone in sequence. The PCB conveying system in the zone also includes a thermal energy recycling system arranged above the preheating zone and the welding zone, and the thermal energy recycling system includes a preheating zone air inlet channel 1 and a preheating zone air inlet channel 2 5. Heat recovery channel 4, pipeline fan 7, filter 8, welding zone air outlet channel one 9, welding zone air outlet channel two 11 and cold and hot combined air outlet channel 13, the left end of the heat recovery channel 4 is connected to the preheating zone The first air inlet passage 3 and the second air inlet passage 5 in the preheating area are all connected, the right end of the heat recovery passage 4 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com