Photovoltaic bus bar welding terminal testing table

A technology for welding terminals and busbars, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as inconvenience in production, and achieve the effect of good use effect, saving installation process and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

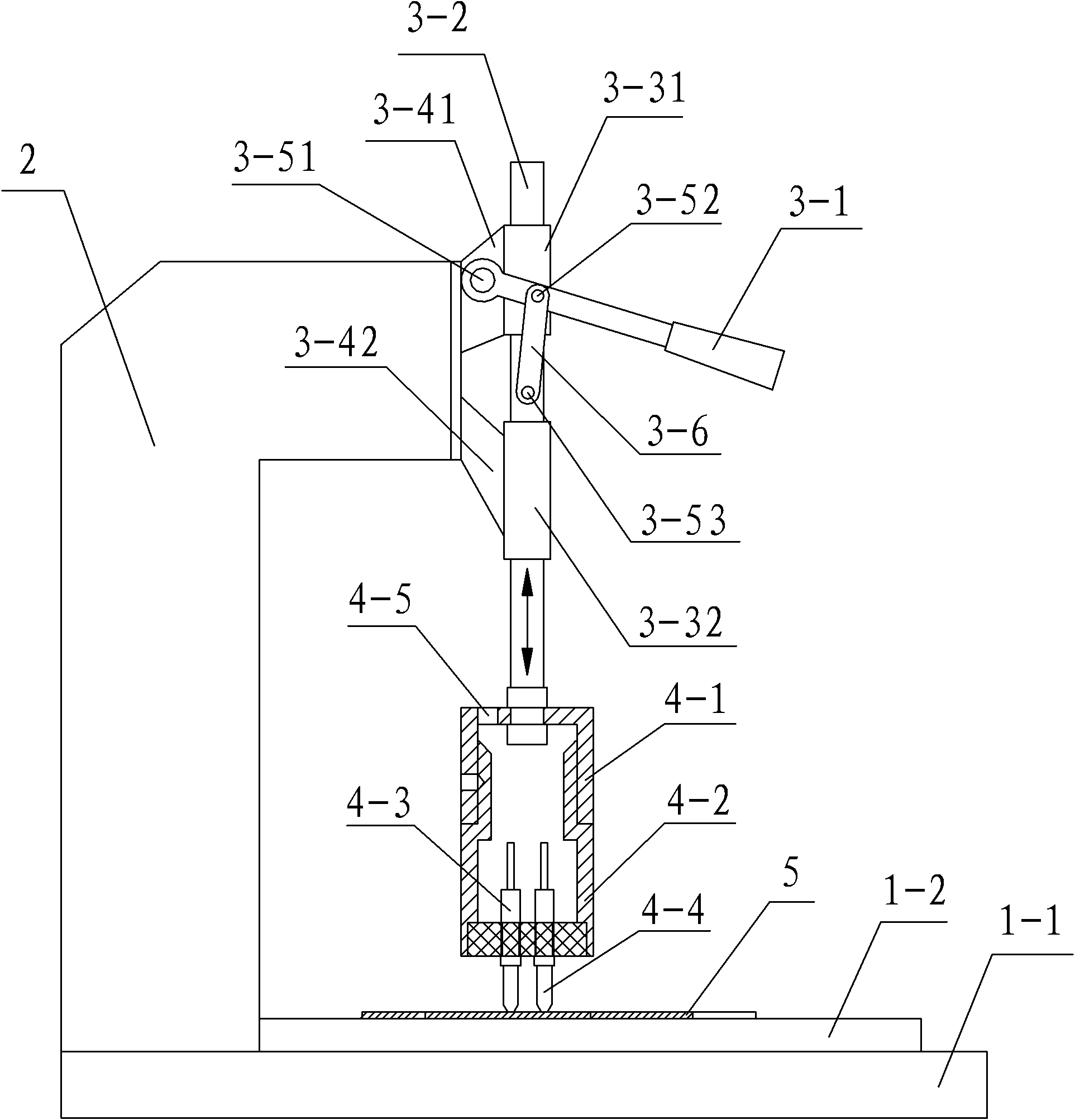

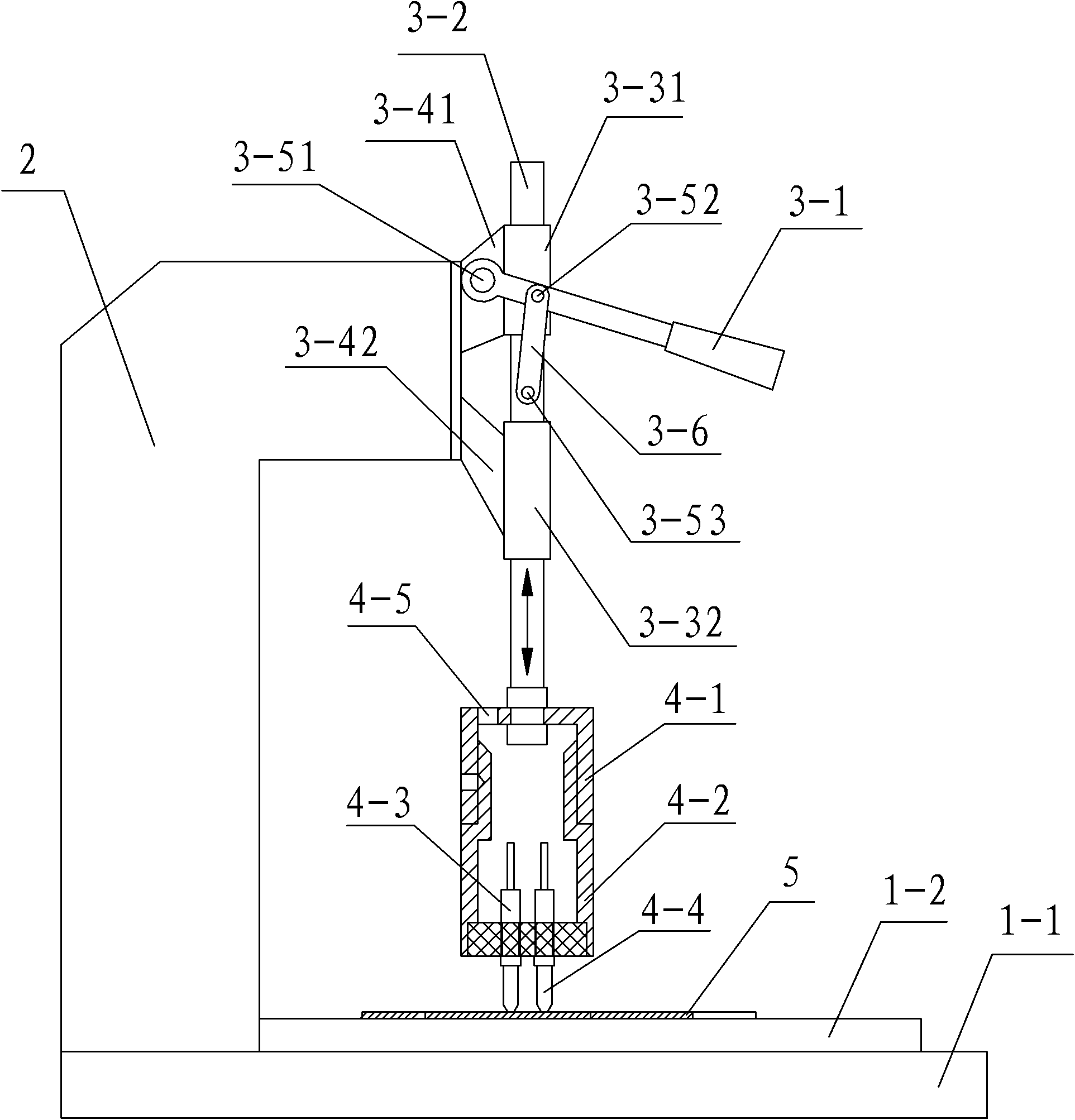

[0019] Such as figure 1 As shown, the present invention includes a photovoltaic busbar base for placing the photovoltaic busbar 5 under test and a bracket 2 connected to one end of the photovoltaic busbar base, the upper end of the bracket 2 is connected with a lifting mechanism, and the lower end of the lifting mechanism is connected to There is a probe assembly for testing the welding terminals of the photovoltaic busbar; the lifting mechanism is composed of a lifting handle 3-1, a lifting rod 3-1 connected to the lifting handle 3-1 and driven by the lifting handle 3-1 to perform lifting movement 2 and a lifting sleeve socketed on the outside of the lifting rod 3-2, the lifting sleeve includes a lifting sleeve 3-31 fixedly connected to the bracket 2 through the sleeve fixing plate 3-41 and fixed by the sleeve Plate two 3-42 is fixedly connected to the lifting sleeve two 3-32 of the bracket 2, and the lifting handle 3-1 is connected with the sleeve fixing plate one 3-41 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com