Full variable fertilizing device capable of adjusting fertilizer sowing quantity and proportion and control method thereof

A technology of a fertilization device and a control method, which is applied to the fertilization device, fertilizer distributor, agricultural gas emission reduction and other directions, can solve the problems such as the inability to control the amount and ratio variables online, the large time lag of variable fertilization control, and the inability to grow vigor differences. , to achieve the effect of short system response time, elimination of easy stratification, and optimization of fertilization prescriptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

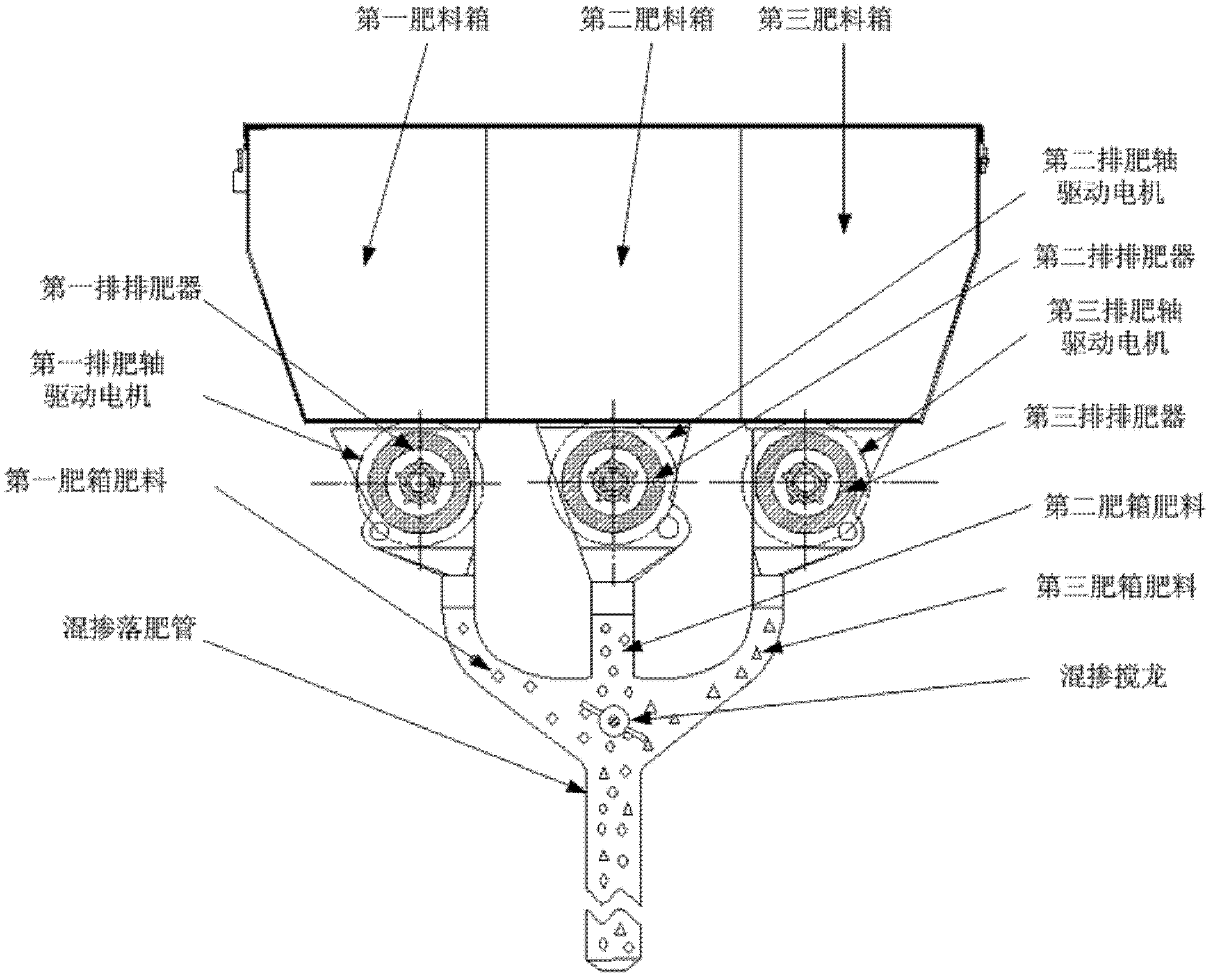

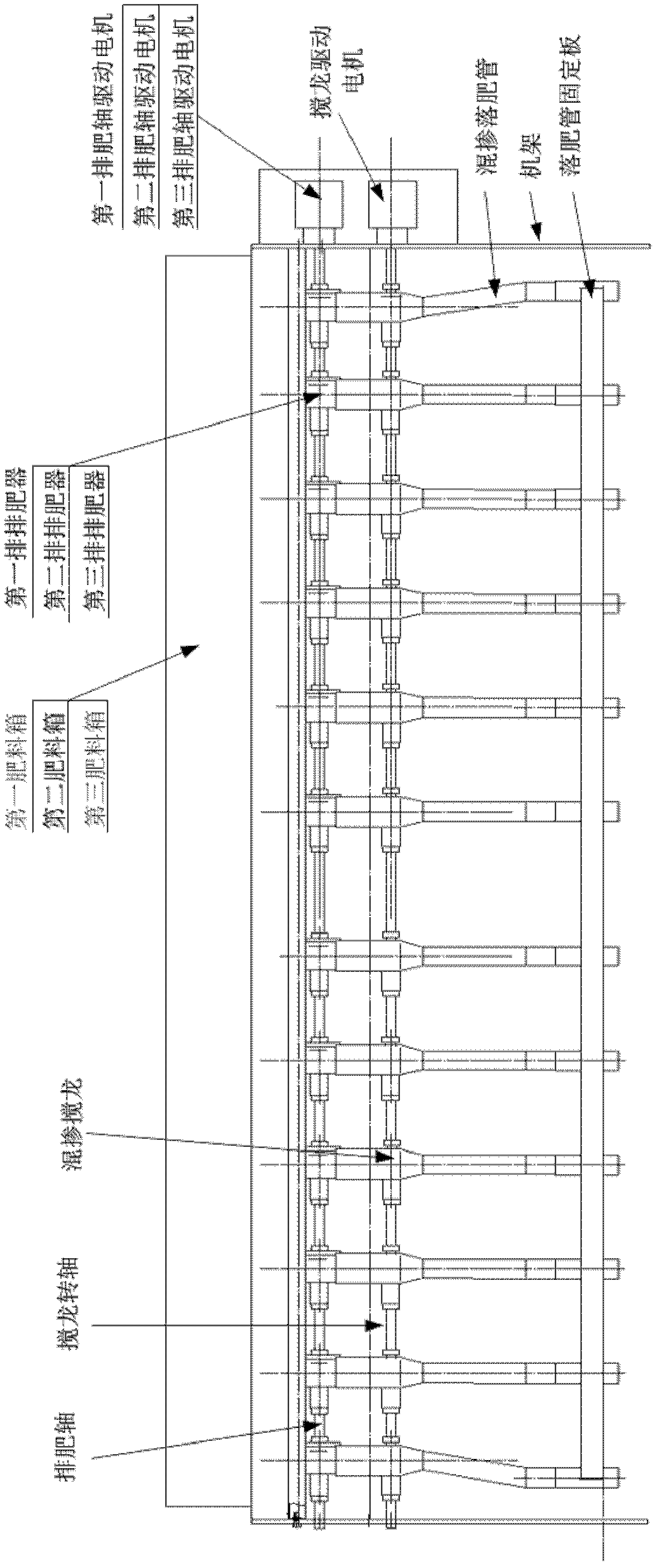

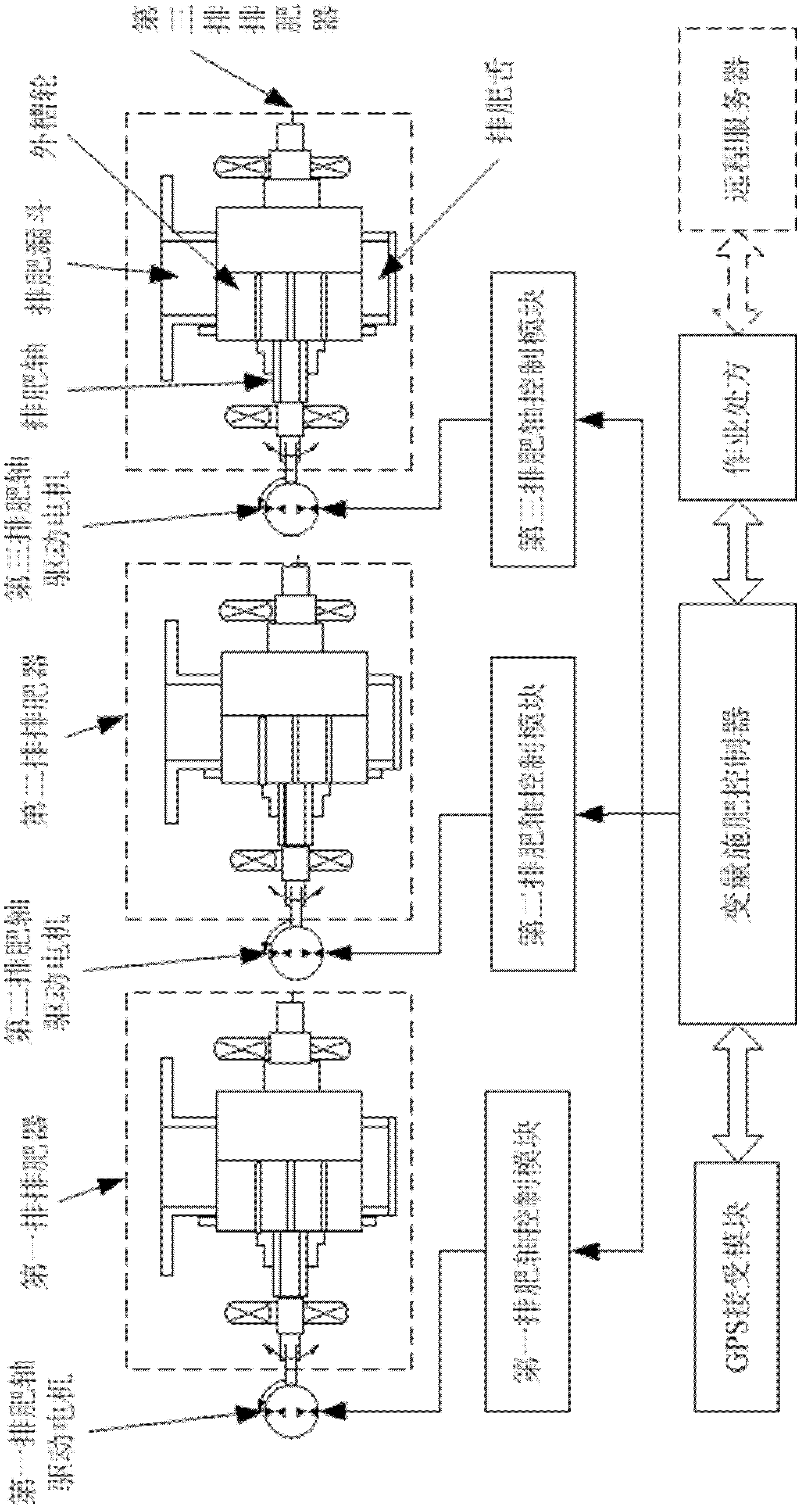

[0032] Such as figure 1 , figure 2 As shown, the first fertilizer box, the second fertilizer box, the third fertilizer box, the first row of fertilizer discharger, the first row of fertilizer shaft drive motor, the second row of fertilizer discharger, the second row of fertilizer shaft drive motor, the third row of fertilizer The fertilizer discharge device, the drive motor of the third fertilizer discharge shaft, the mixing fertilizer dropping pipe, the mixing mixing auger, and the fertilizer dropping pipe fixing plate form the mechanical device part.

[0033] The fertilizer discharger is located at the bottom of the fertilizer tank, and is fixedly connected to the bottom of the fertilizer tank through bolts; the fertilizer discharger adopts an outer groove wheel type fertilizer discharger, which consists of a fertilizer discharge funnel, an outer groove wheel for fertilizer discharge and a baffle for fixing, Composed of pins; the fertilizer discharge funnel is located abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com