Lathe and method for processing external thread of screw

A processing method and external thread technology, which is applied in the field of lathes, can solve problems such as hindering elongation, large thermal deformation elongation, and affecting processing quality, so as to avoid processing errors and ensure the accuracy of external threads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Utilize the ordinary lathe to process the external thread of the slender screw, adopt the following steps:

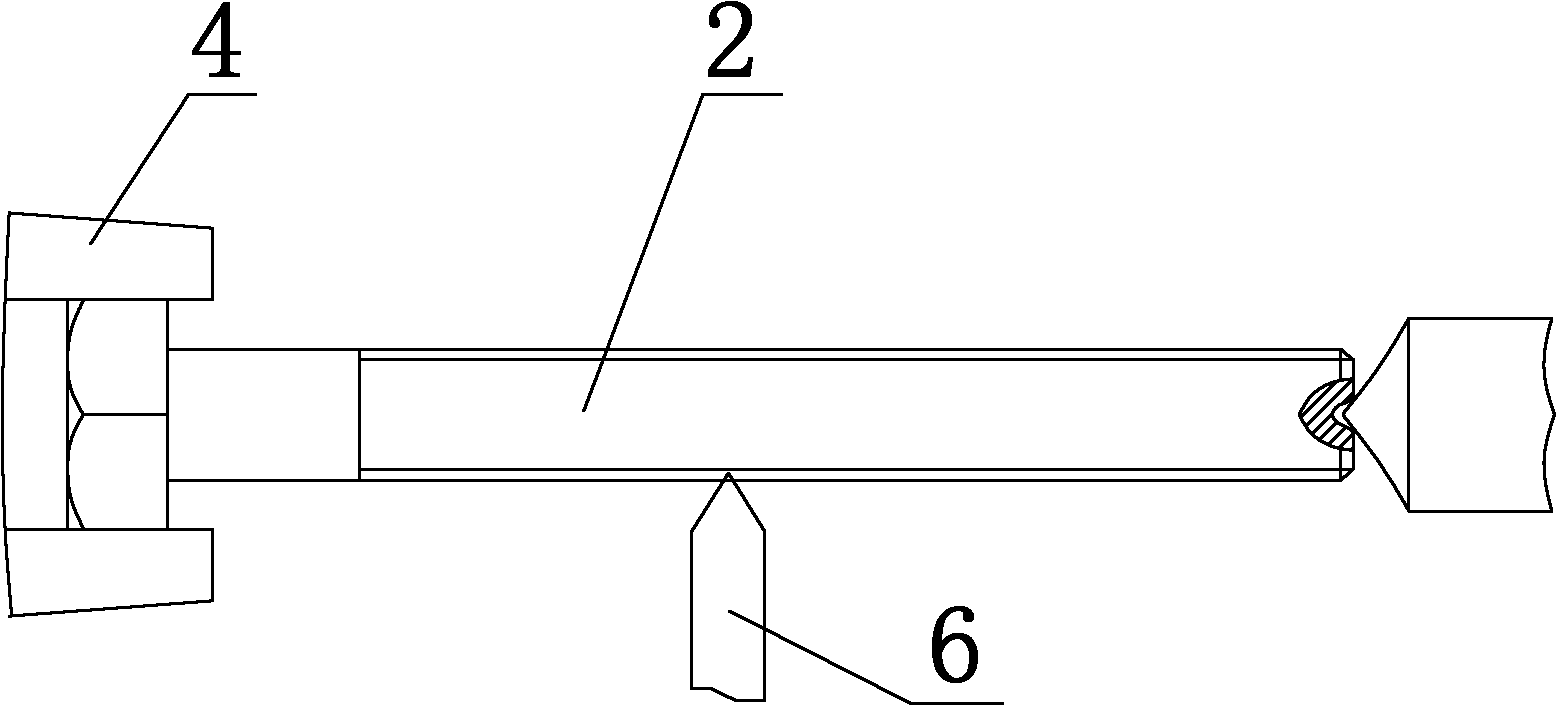

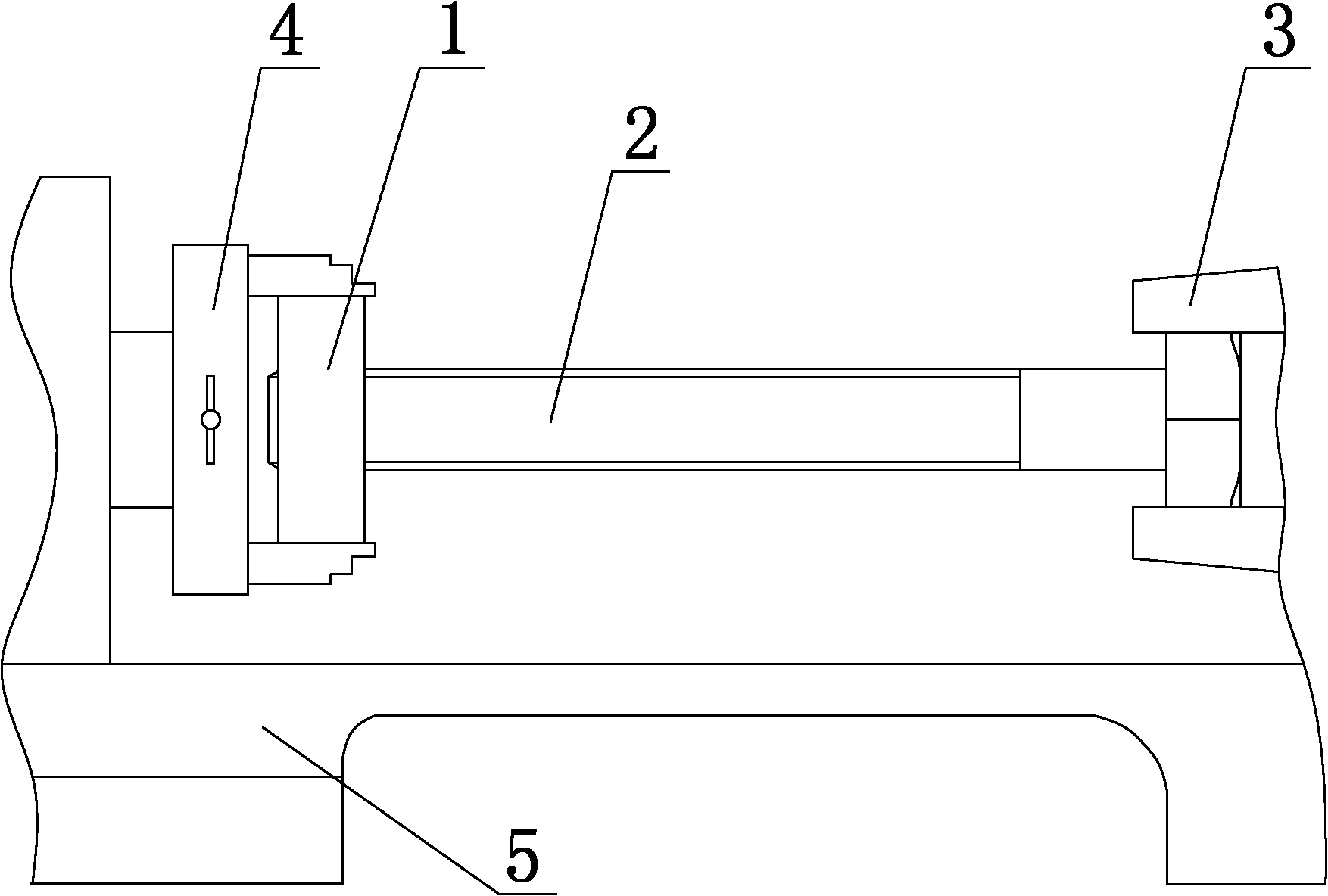

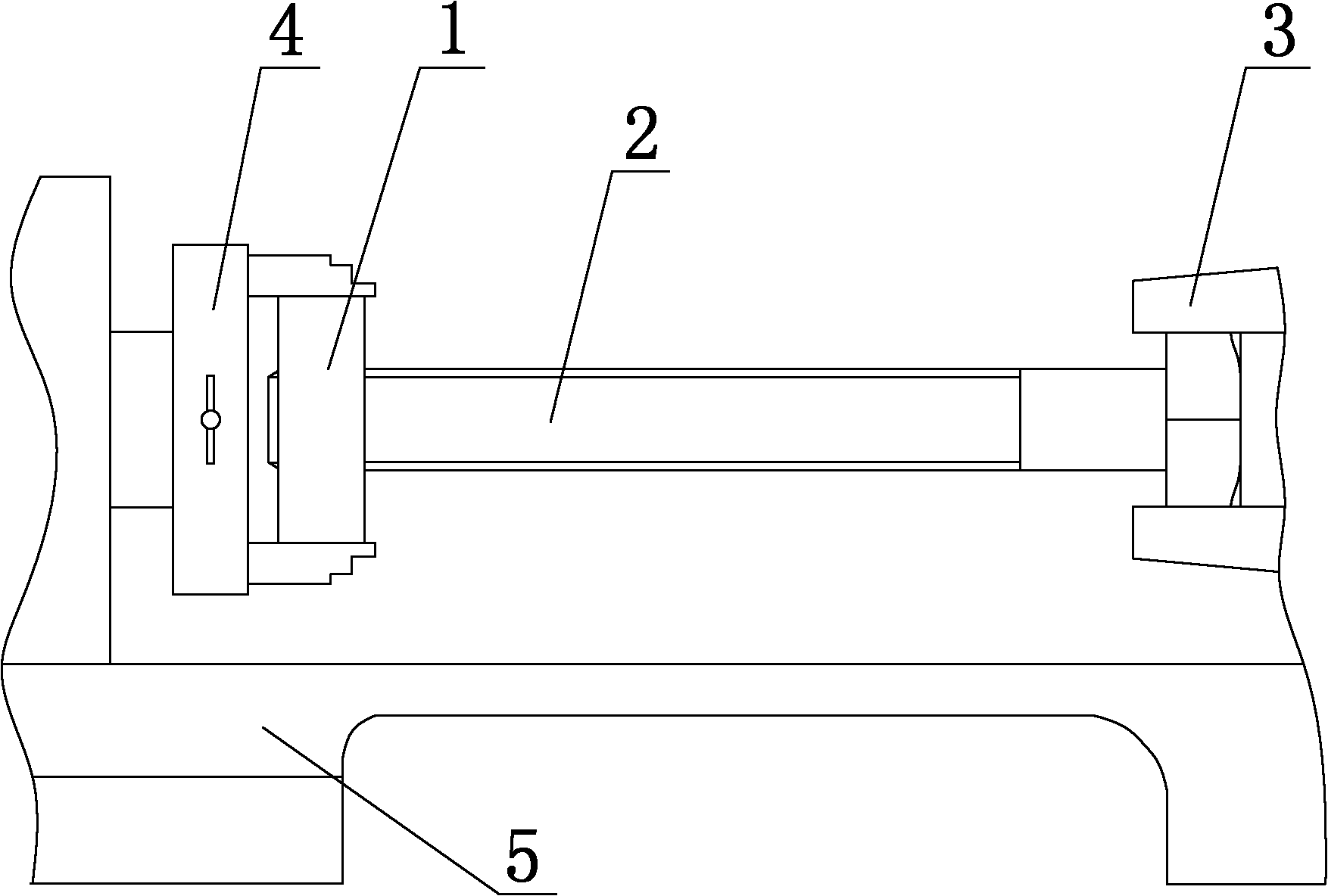

[0028] A. Select the external thread die 1 that matches the external thread to be processed on the workpiece 2, and install the external thread die 1 coaxially on the chuck 4. The external thread die 1 is an ordinary hand twisted external thread die. Can;

[0029] B. Install the workpiece 2 between the external thread die 1 and the tailstock 3 and ensure that the three are coaxial. The tailstock 3 can use an ordinary center frame. After the workpiece 2 is installed, the center frame is not fixed on the guide rail. It is necessary to ensure the state of axial movement;

[0030] C. Turn on the lathe to make the chuck 4 drive the externally threaded die 1 to rotate, so that the externally threaded die 1 can process the external thread on the workpiece 2, and pour cooling liquid on the processing part of the workpiece 2 in time during processing;

[0031] D. After ...

Embodiment 2

[0034] Use the following steps to process the external thread of a slender screw:

[0035] A. Select the external thread die 1 that matches the external thread to be processed on the workpiece 2, and install the external thread die 1 coaxially on the chuck 4. The external thread die 1 is an ordinary hand twisted external thread die. Can;

[0036] B. Install the workpiece 2 between the external thread die 1 and the tailstock 3 and ensure that the three are coaxial. The tailstock 3 adopts a special tailstock 3, and its lower part has a chute and a positioning bolt installed on the guide rail of the machine base 1. The upper part has an inner hexagonal through hole, and the workpiece 2 is directly inserted into the inner hexagonal through hole on the tailstock 3;

[0037] C. Turn on the lathe so that the chuck 4 drives the externally threaded die 1 to rotate, so that the externally threaded die 1 processes the external thread on the workpiece 2, and pours cooling liquid on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com