Device for automatically welding 90-degree large elbow

An automatic welding and pipe bending technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem that the trolley cannot realize automatic welding, etc., and achieve the effect of easy operation of the control mode, accelerated production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

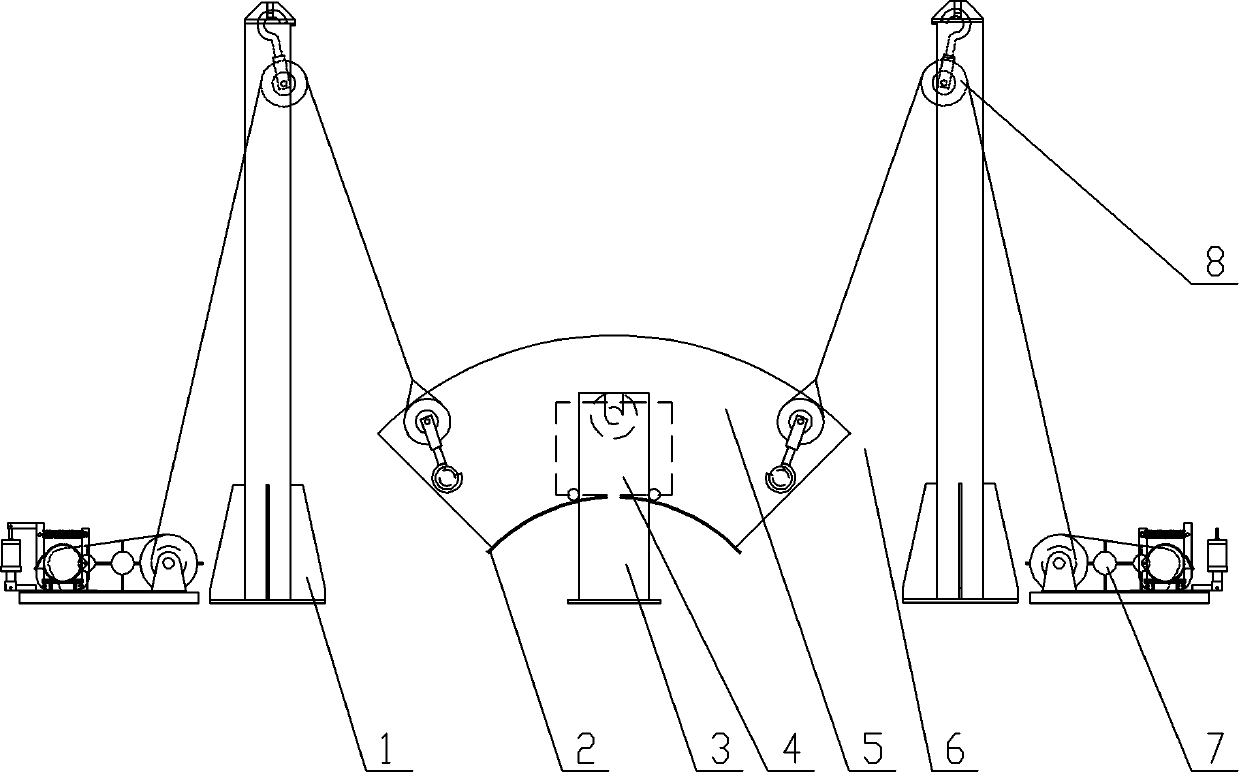

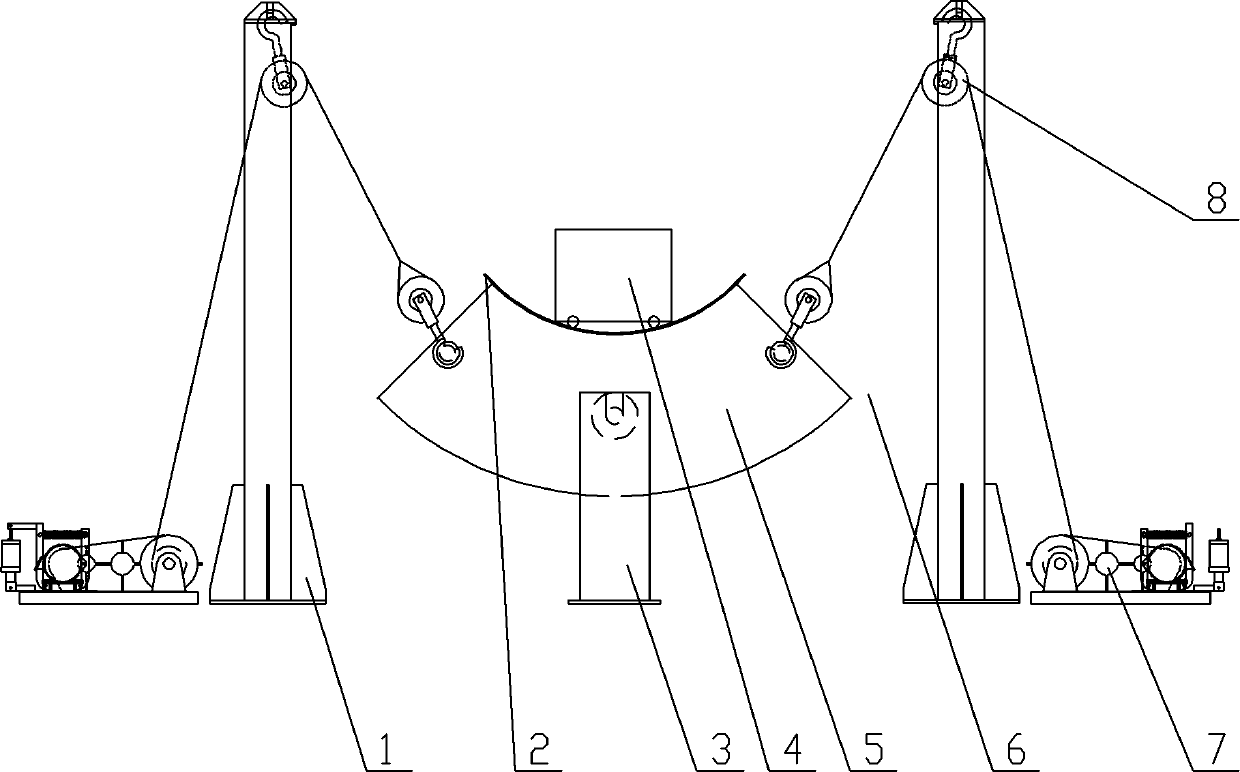

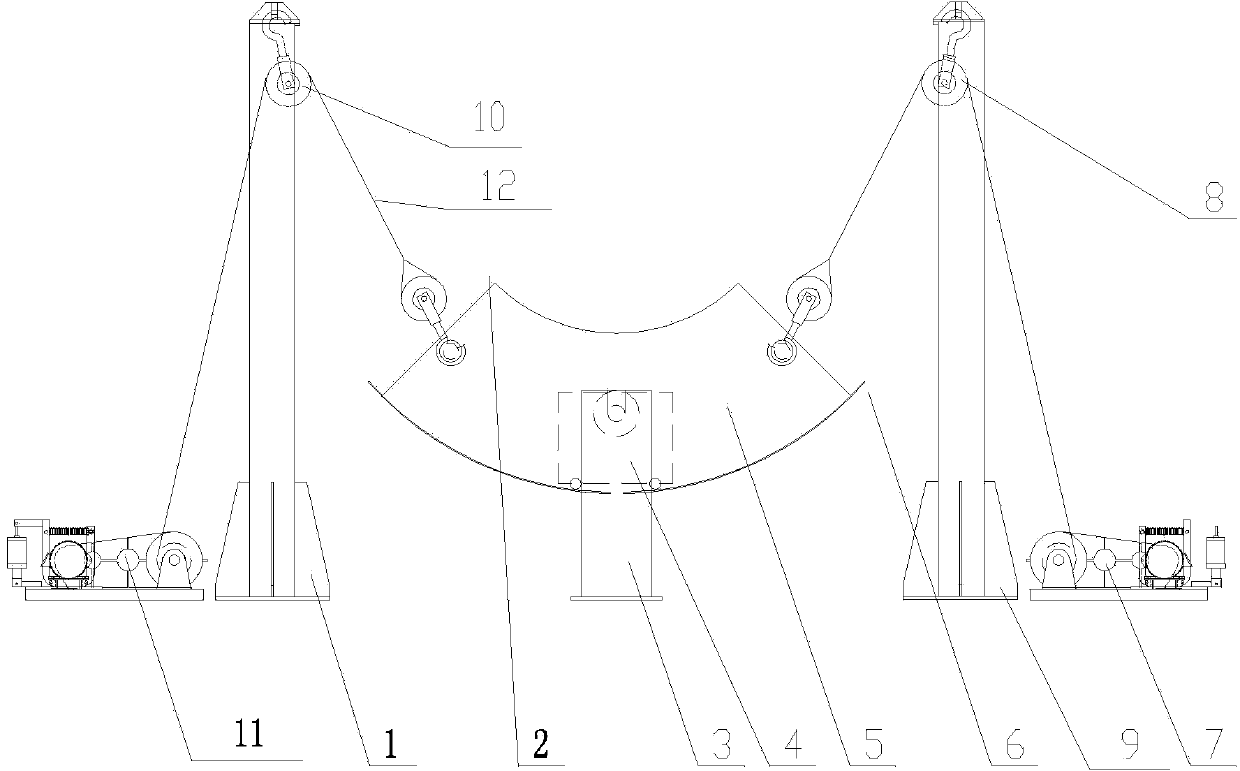

[0011] The present invention will be further described below in conjunction with specific drawings.

[0012] Such as Figure 1 to Figure 4 Shown: The 90-degree large-scale pipe bending automatic welding device includes the first pillar 1, the trolley track 2, the pipe bending rotating support 3, the submerged arc welding trolley 4, the pipe bending 5, the second steel wire rope 6, the second hoist 7, and the second pulley 8. The second pillar 9, the first pulley 10, the first winch 11, the first wire rope 12, etc.

[0013] The present invention includes an elbow rotating bracket 3, on both sides of the elbow rotating bracket 3 are respectively provided with a first pillar 1 and a second pillar 9; With the second pulley 8, a first hoist 11 is installed on one side of the first pillar 1, and a second hoist 7 is installed on one side of the second pillar 9, and one end of the second wire rope 6 is fixed on the second hoist 7 Above, one end of the first wire rope 12 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com