Mechanical arm with frame-type extension arm

A technology of extending arms and manipulators, which is applied in the field of manipulators, can solve problems such as limited operating range and range, small grasping weight, and complex structure, and achieve the effect of wide operating range, large grasping weight, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

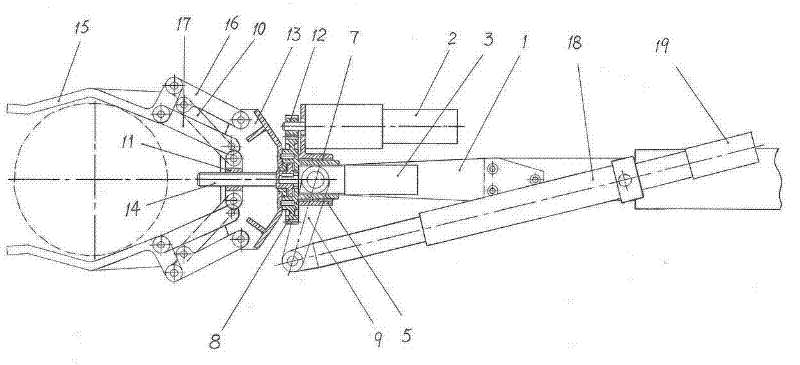

[0017] The manipulator of the present invention includes parts such as a support arm, a wrist raising mechanism, a wrist turning mechanism, and a pick-and-place mechanism.

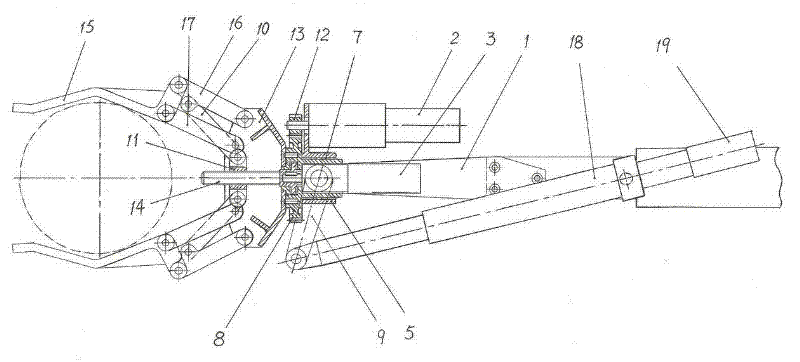

[0018] Such as figure 1 As shown, the wrist lifting mechanism of this manipulator is to hinge a telescopic rod 18 on the support arm 1, the telescopic rod driving mechanism 19 is connected to the rear end of the telescopic rod 18, and the front end of the telescopic rod 18 is hinged to the first connecting rod 9, the first The other end of the connecting rod 9 is connected to the wrist base 5, and the wrist base 5 is hinged to the front end of the support arm 1 through a pin. The telescopic rod driving mechanism 19 adopts a DC brushed servo motor, which controls the extension and retraction of the telescopic rod 18 through the rotation of the motor, and pulls the wrist base 5 through the linked first connecting rod 9 to realize the wrist in the Pitch motion within a certain angle.

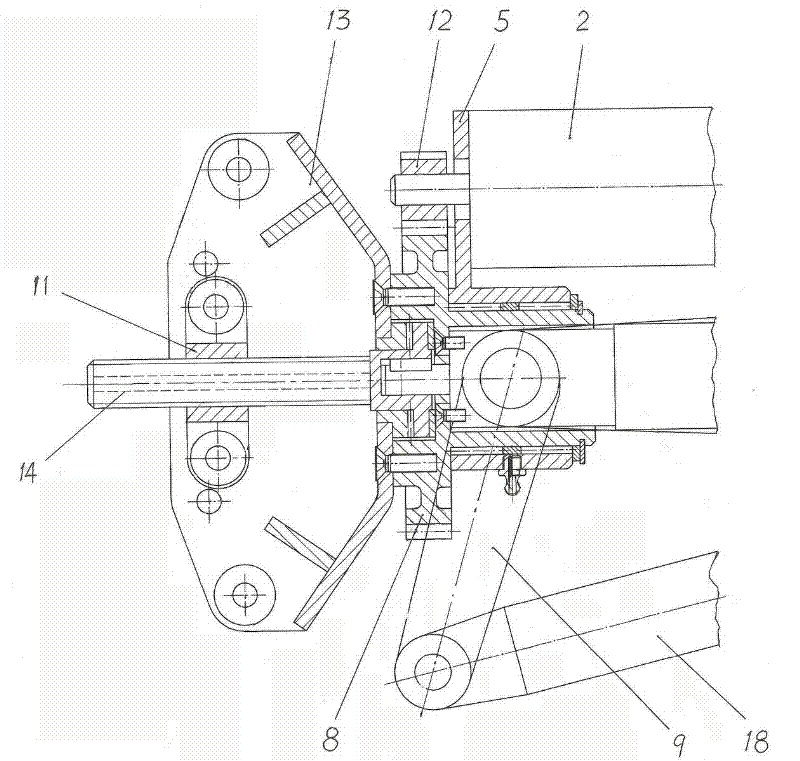

[0019] figure 2 Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com