Plastic mould self-heating device

An automatic heating, plastic mold technology, applied in the field of mold heating devices, can solve the problems of uncontrolled heating temperature, unstable liquefied gas exhaust volume, unstable flame size, etc., achieving good control, good power saving effect, close-knit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings.

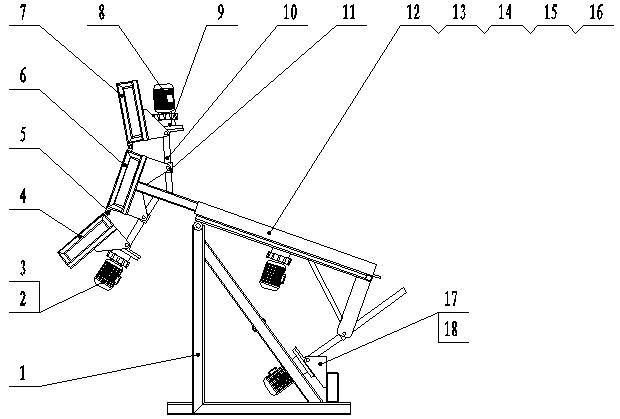

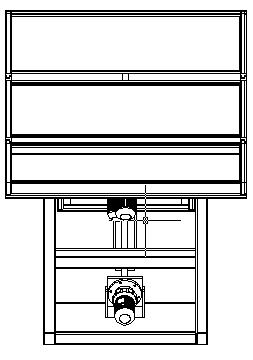

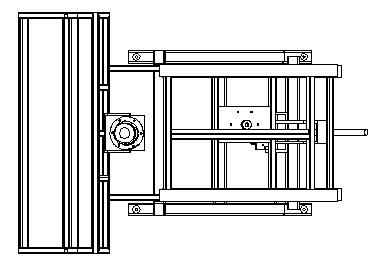

[0018] The part numbers in the figure are: main body frame 1, lower heating device motor 2, lower heating device reducer 3, lower heating device 4, universal regulator 5, middle heating device 6, upper heating device 7, upper heating device motor 8, Upper heating device reducer 9, leading screw 10, screw nut 11, telescopic beam 12, telescopic beam motor 13, telescopic beam reducer 14, gear 15, rack 16, telescopic beam bottom motor 17, telescopic beam bottom speed reducer 18.

[0019] The upper and lower heating devices of the heater of the present invention are connected to lead screws and nuts through the lower heating device motor 2, the upper heating device motor 8, the lower heating device reducer 3, and the upper heating device reducer 9, and rotate around the middle heating device. The telescopic beam moves back and forth, and can rotate up and down at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com