Underwater folding method for half ships

A hull and dock technology, applied in the field of precision control of half-ship closing, can solve problems such as heavy weight and inapplicability, and achieve the effects of ensuring safety, saving costs, and saving core resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A half-ship underwater closing method, the following steps are used to complete:

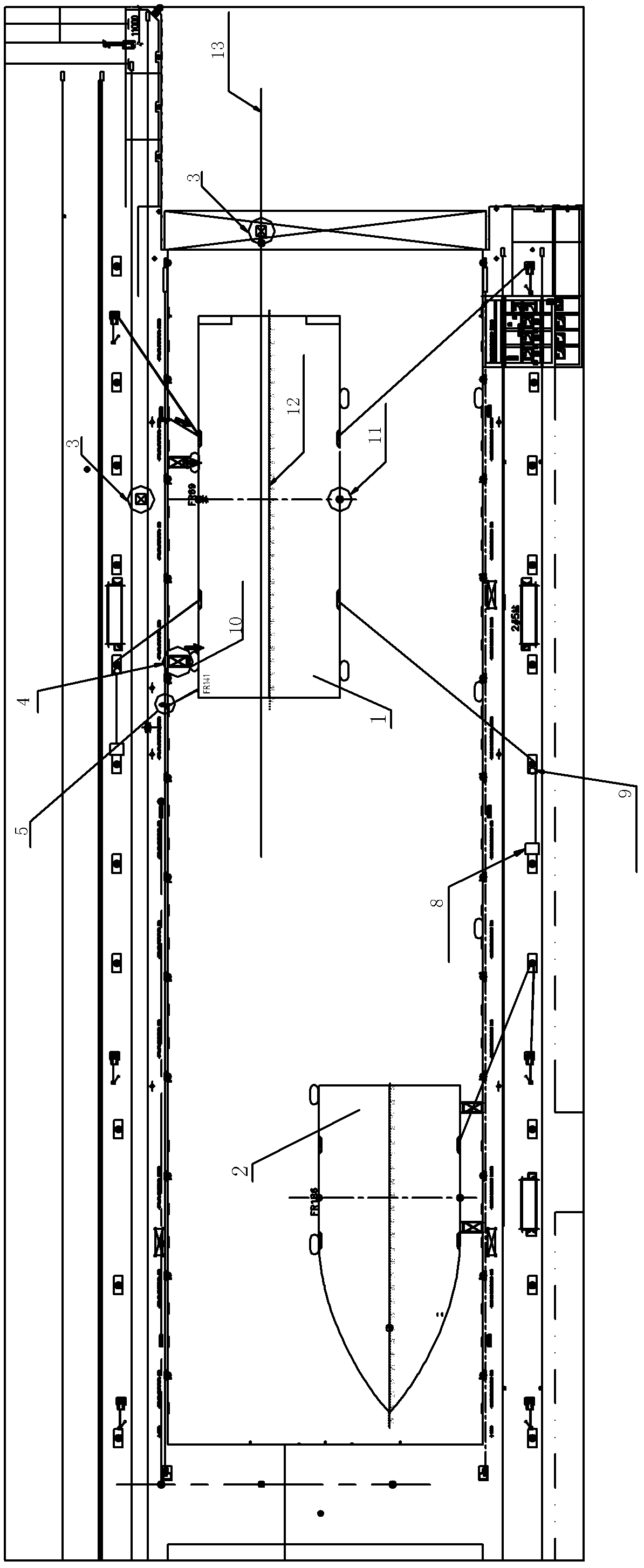

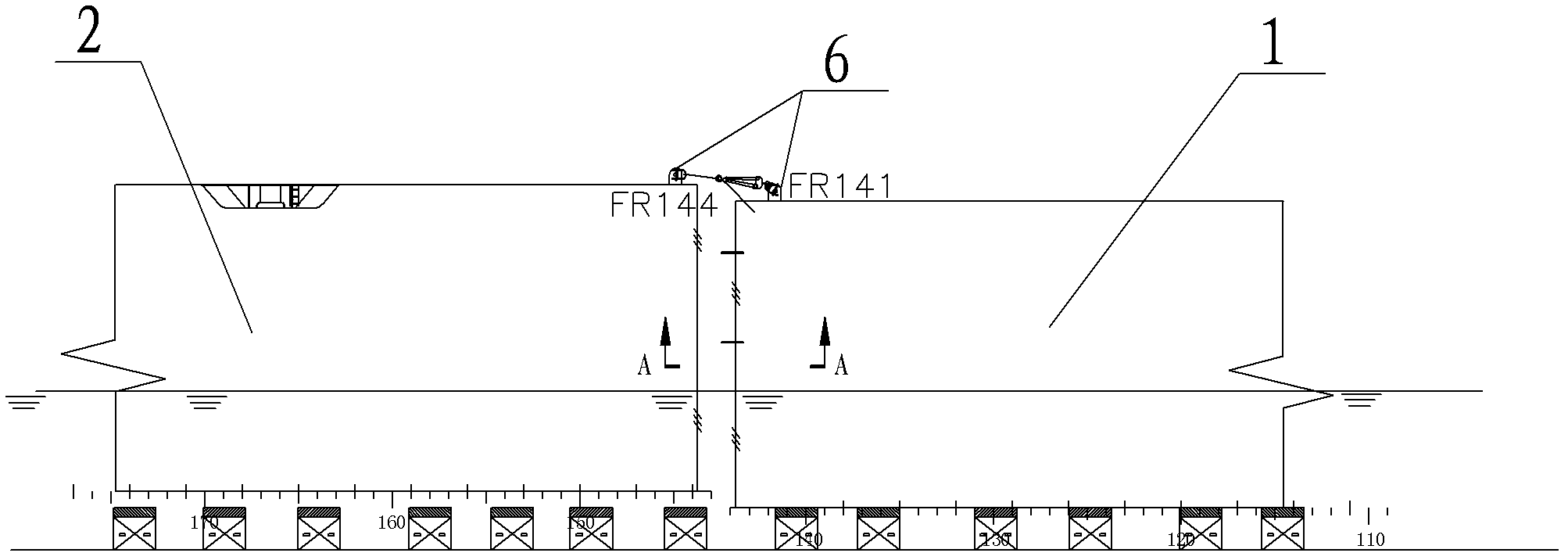

[0046] 1) if figure 1 As shown, the two halves of the ship are carried and built independently in the dock, and the data of the half of the ship’s end surface (such as Figure 8 shown) as a basis to carry the other half of the ship, so that the same plane of the closing mouth of the two halves of the ship meets the requirements;

[0047] 2) Draw the baseline of the whole ship at the pre-closed dock position, and arrange half dock piers at the height of this baseline;

[0048] 3) Arrange the precision measuring instrument 3 on the dock wall and dock door, and mark the captain mark and the center line of the hull behind the pier;

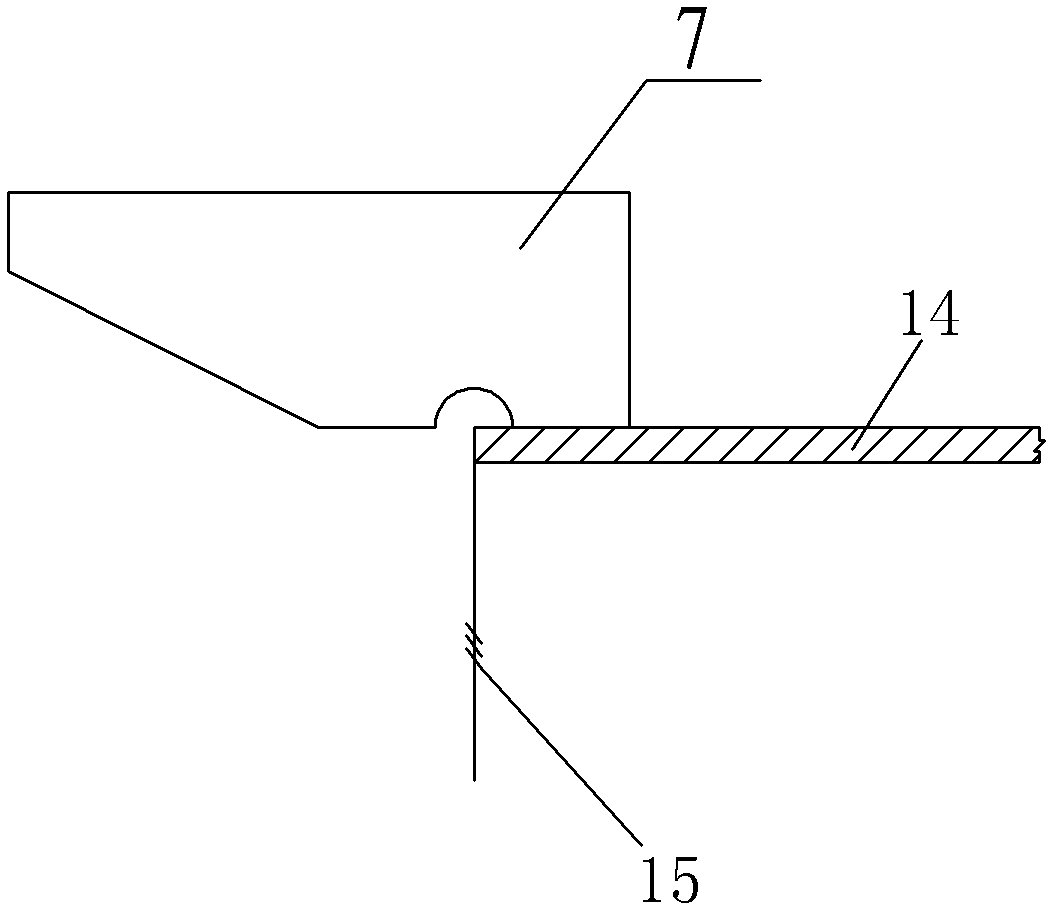

[0049] 4) Arrange the hanging codes and guide plates 7 installed on the outer plates of the half-hulls, the light targets attached to the outer plates of the half-hulls, and the pullers 5 installed on the dock wall tracks, and installed on the inner walls of th...

Embodiment 2

[0059] A half-ship underwater closing method, the following steps are used to complete:

[0060] 1) if figure 1 As shown, the two halves of the ship are built independently in the dock. When the half ships are carried separately, steel docking piers are used in the center longitudinal keel area to prevent the uneven sinking of the pier due to the uneven weight of the hull during the loading process. Guarantee the accuracy requirements of the baseline of the bottom of the ship after closing; Figure 8 shown) as the basis to carry the other half of the ship, so that the same plane of the closing mouth of the two halves of the ship is within the range of ±8mm;

[0061] 2) Draw the baseline of the whole ship at the pre-closed dock position, and arrange half dock piers at the height of this baseline, and arrange steel dock piers on the nearest row of dock piers on both sides of the closing port to reduce the pitch of the pier due to the trimming of the half ship. The influence of...

Embodiment 3

[0073] A half-ship underwater closing method, the following steps are used to complete:

[0074] 1) if figure 1 As shown, the two halves of the ship are built independently in the dock. When the half ships are carried separately, steel docking piers are used in the center longitudinal keel area to prevent the uneven sinking of the pier due to the uneven weight of the hull during the loading process. Guarantee the accuracy requirements of the baseline of the bottom of the ship after closing; Figure 8 shown) as the basis to carry the other half of the ship, so that the same plane of the closing mouth of the two halves of the ship is within the range of ±8mm;

[0075] 2) Draw the baseline of the whole ship at the pre-closed dock position, and arrange half dock piers at the height of this baseline, and arrange steel dock piers on the nearest row of dock piers on both sides of the closing port to reduce the pitch of the pier due to the trimming of the half ship. The influence of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com