Movable-arm tower crane

A technology of tower cranes and booms, which is applied in the direction of cranes, etc., can solve problems such as the rigidity or high rigidity of the boom and the top of the tower, difficulty in ensuring machining accuracy, and complicated manufacturing of the lower support, so as to save transportation costs and stress Reasonability and the effect of safety performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

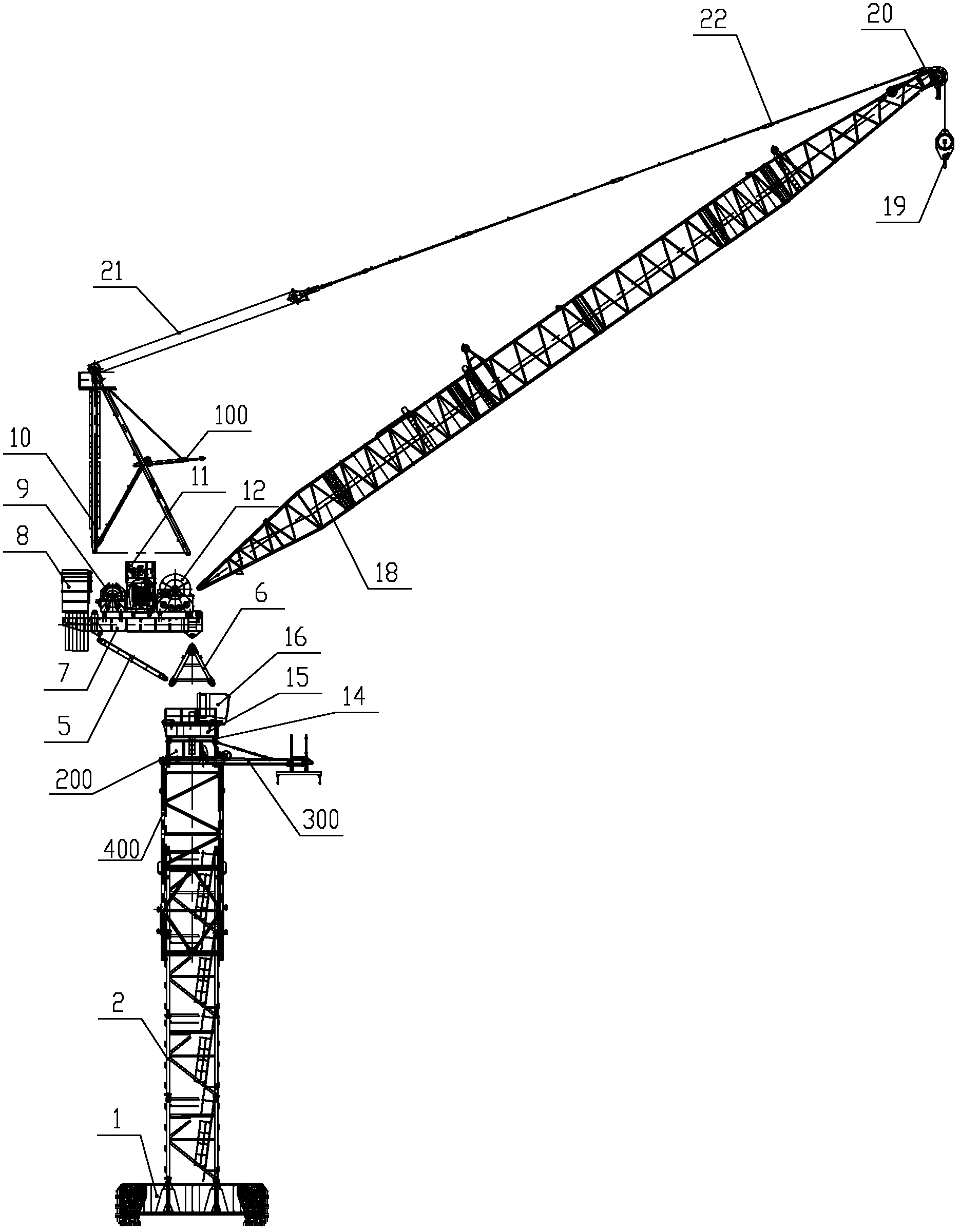

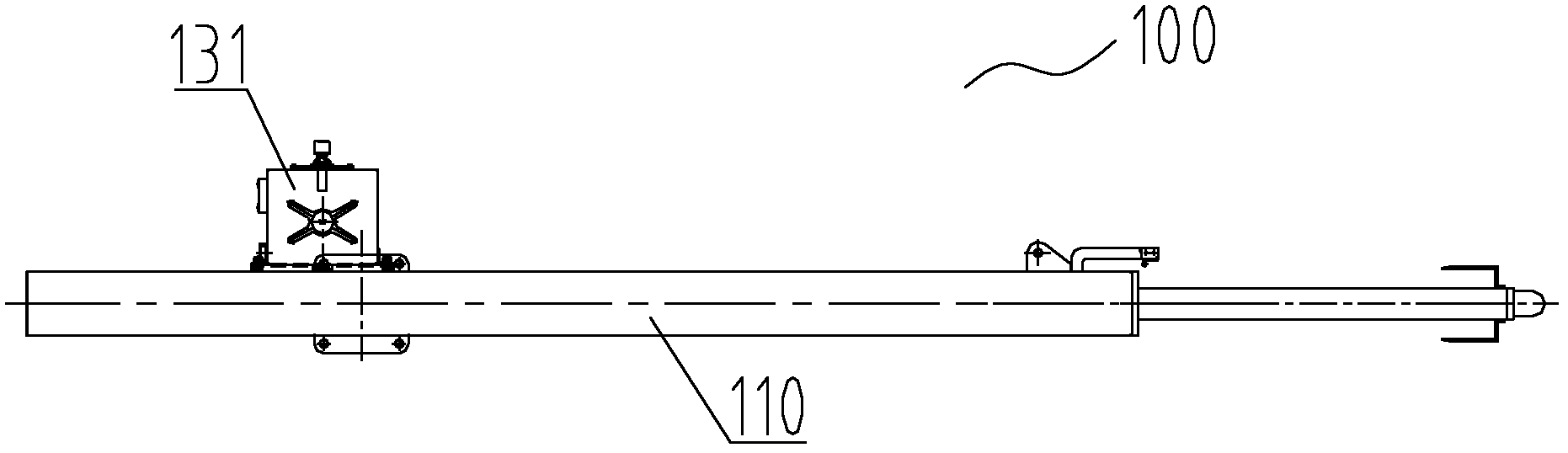

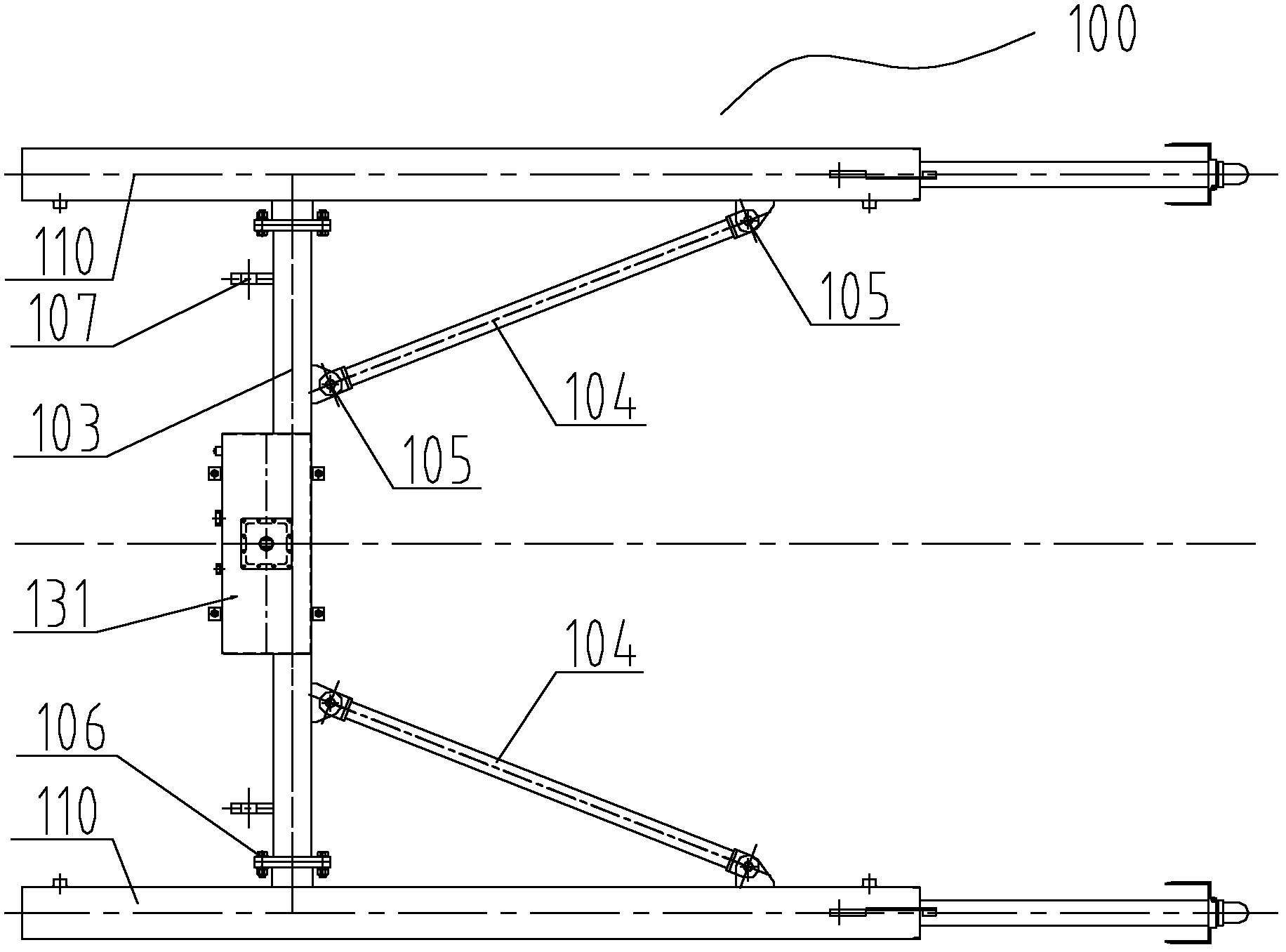

[0082] Such as figure 1 As shown, the boom tower crane of this embodiment mainly includes a fixed foundation 1, several standard sections 2, a climbing frame 400, a lower support 200, a balance arm strut 5, a slewing tower body 6, a balance arm 7, and a balance weight 8. Luffing mechanism 9, A frame 10, power pack 11, hoisting mechanism 12 (including hoisting rope), introduction system 300, slewing bearing 14, upper support 15, cab 16, anti-backward device 100, Lifting arm 18, hook assembly 19, anti-twist device 20, luffing wire rope 21, luffing rod 22, etc.

[0083] The standard sections 2 of the tower body are all integral structures, and the standard sections 2 are connected by pin shafts....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com